镁合金的阳极氧化处理

ANODIZING OF MAGNESIUM ALLOYS

1. INTRODUCTION 介绍

A. The data in this subject comes from Boeing Process Specifications BAC5734 and 5742. The airline has a copy of the Boeing Process Specification Manual.

本主题中的数据来自波音工艺规范 BAC5734 和 5742。航空公司有一本《波音工艺规范手册》。

B. The data is general. It is not about all situations or specific installations. Use this data as a guide to help you write minimum standards.

数据是通用的。并不涉及所有情况或特定安装。请将此数据作为指南,帮助您编写最低标准。

C. The Dow 17 process makes a coating upon magnesium alloys by electrolytic treatment in a chromic acid-phosphoric acid solution. This coating has types and classes which are equivalent to MIL-M-45202 types and classes: Type 1, Class C, which is a thin light green coating, and Type 2, Class D, which is a heavy dark green coating. If the type or class is not specified by the overhaul instructions, use Type 1, Class C. Equivalent procedures that agree with MIL-M-45202, Type 1, Class C, or Type 2, Class D, can be used unless the parts are to be adhesive bonded.

Dow 17 工艺通过在铬酸-磷酸溶液中进行电解处理,在镁合金上形成涂层。这种涂层的类型和等级相当于 MIL-M-45202 的类型和等级: 类型 1,C 级,为浅绿色薄涂层;类型 2,D 级,为深绿色厚涂层。如果大修说明中没有规定类型或等级,则使用类型 1,C 级。可以使用与 MIL-M-45202、类型 1,C 级或类型 2,D 级一致的等效程序,除非零件要进行粘接。

D. The Dow 19 process is a manually applied anodize that uses a solution of chromic acid and calcium sulfate. The BMC process is an immersion applied anodize.

Dow 19 工艺是一种使用铬酸和硫酸钙溶液的手工阳极氧化工艺。BMC 工艺是一种浸入式阳极氧化工艺。

E. These coatings are used as a base for paints and adhesives.

这些涂层用作油漆和粘合剂的基底。

F. Refer to SOPM 20-00-00 for a list of all the vendor names and addresses.

所有供应商的名称和地址请参见 SOPM 20-00-00。

2. MATERIALS 材料

A. Dow 17 Process

Dow 17 流程

(1) Ammonium Bifluoride, Technical Grade

氟化氢铵,工业级

(2) Sodium Dichromate Dihydrate, Technical, O-S-595

重铬酸钠,工业级,O-S-595

(3) Phosphoric Acid (Orthophosphoric Acid) Technical, O-O-670

工业级磷酸(正磷酸),O-O-670

(4) Maskants

遮蔽剂

(a) Adcoat 828, V51686

(b) Aluminum tape — Scotch No. 425, V76381

(c) Lead tape — Scotch No. 420, V76381

(d) Turco 5696, V61102

B. Dow 19 Process

Dow 19 工艺

(1) Chromic Acid (Chromium Trioxide), technical, O-C-303

工业铬酸(三氧化二铬),O-C-303

(2) Calcium Sulfate (CaS04 2H20), technical

工业级硫酸钙 (CaS04 2H20)

(3) Sodium Hydroxide, technical, O-S-598

工业级氢氧化钠,O-S-598

(4) Sulfuric Acid, O-S-89

硫酸,O-S-89

(5) Magnesium Oxide, technical, MIL-M-12036

技术用氧化镁,MIL-M-12036

C. BMC Dip Process

BMC 浸渍工艺

(1) Sodium Dichromate Dihydrate, technical, O-S-595

二水重铬酸钠,工业级,O-S-595

(2) Sodium Sulfate, technical

工业级硫酸钠

(3) Chromic Acid (Chromium Trioxide), technical, O-C-303

铬酸(三氧化铬),工业级,O-C-303

D. Wipers — BMS 15-5, class A or B

擦拭布–BMS 15-5,A 级或 B 级 3.

3. DOW 17 ANODIZING PROCESS DOW 17 阳极氧化工艺

A. General Notes

通用说明

(1) Anodize the parts after they are machined (as in repair) and before assembly and operations during installation, such as trimming and drilling.

在零件加工后(如维修)、装配前和安装过程中的操作(如修边和钻孔)前对零件进行阳极氧化处理。

(2) The Dow 17 coating makes a buildup that is equivalent to 2/3 of the coating thickness. For example, a 0.0015 inch thick coat makes a 0.0010 inch buildup.

Dow 17 涂层的堆积相当于涂层厚度的 2/3。例如,0.0015 英寸厚的涂层会产生 0.0010 英寸的堆积。

(3) The procedure can be done with AC (50-70 Hz) or DC systems. For a DC system, use the steel tank as the cathode or use steel cathodes. The parts are the anode. The cathode-to-anode area ratio must be 3 to 1 or larger. For AC systems, two electrodes are necessary, with area ratios as nearly equal as possible, and no more different than 2 to 1. These electrodes could be two of the same unit or group of parts, or one part with something else as the other electrode.

该程序可使用交流(50-70 Hz)或直流系统。对于直流系统,使用钢槽作为阴极或使用钢为阴极。零件为阳极。阴阳极面积比必须为 3 比 1 或更大。对于交流系统,必须有两个电极,面积比尽可能接近相等,相差不超过 2 比 1。这些电极可以是同一单元或零件组中的两个,也可以是一个零件,用其他东西作为另一个电极。

(4) Automatic electrical equipment is recommended, to control current density and time that the current is on.

建议使用自动电气设备,以控制电流密度和通电时间。

(5) For racks, use magnesium. As an alternative, 5000- or 6000-series aluminum racks can be used if inhibited alkaline cleaners are used. Mask all parts of the rack that will not be electrical connections to the parts.

支架应使用镁。如果使用抑制性碱性清洁剂,也可使用 5000 或 6000 系列铝制机架。屏蔽机架上所有不会与零件电气连接的部分。

(6) Surfaces must be water break-free after immersion or spray in a solution or rinse, but not after vapor degreasing or emulsion cleaning.

在溶液中浸泡或喷淋或冲洗后,表面必须无断水,但在蒸气脱脂或乳液清洗后则不能无断水。

NOTE: A water break-free surface is a surface which keeps a continuous layer of water for 30 seconds after it was rinsed with clean water at a temperature below 100°F. Clean again all surfaces which are not water break-free.

注: 无断水表面是指在温度低于 100°F 的清水冲洗 30 秒钟后,表面仍保持一层连续的水。再次清洗所有无断水的表面。

(7) In the fresh water stage of double counter-current rinsing facilities, or for immersion water rinses, do not let the level of total dissolved solids become higher than 750 parts per million, when parts will stay wet in subsequent procedures, or 350 parts per million, when parts are to be dried.

在双逆流漂洗设备的清水级或浸泡水漂洗中,如部件在随后的程序中将保持湿润,则溶解固体总含量不得超过百万分之 750,如部件将被烘干,则溶解固体总含量不得超过百万分之 350。

B. Solution Makeup and Control

溶液制备和控制

NOTE: The anodize procedure lets you use AC or DC power, but the decision must be made before you make the solution because the ammonium fluoride amounts are different.

注: 阳极氧化程序允许使用交流或直流电源,但必须在配制溶液前作出决定,因为氟化铵的用量不同。

(1) Fully clean the tank. Fill it partially with water.

充分清洗槽。部分加水。

(2) For AC operations, add 2 pounds ammonium bifluoride per gallon of tank values. For DC operations, use 2.5 pounds per gallon. Mix fully.

交流操作时,每加仑槽值加入 2 磅氟化氢铵。对于直流操作,每加仑使用 2.5 磅。充分混合。

(3) Add 0.83 pound sodium dichromate per gallon of tank volume. Add this smoothly all over the surface. Mix fully.

每加仑槽液加入 0.83 磅重铬酸钠。将其均匀地涂满表面。充分混合。

(4) Add 0.11 gallon phosphoric acid per gallon of tank volume.

每加仑槽液加入 0.11 加仑磷酸。

(5) Fill the tank with water. Dissolve and fully mix all chemicals.

向槽中注水。溶解并充分混合所有化学品。

(6) Control fluorides at 20-23 oz/gal (AC operation) or 25-30 oz/gal (DC operation). Control sodium dichromate at 8-14 oz/gal, as Na2Cr2O7.2H2O. Control phosphoric acid at 14-18 oz/gal as H3PO4.

将氟化物控制在 20-23 oz/gal(交流操作)或 25-30 oz/gal(直流操作)。将重铬酸钠控制在 8-14 盎司/加仑(以 Na2Cr2O7.2H2O 计)。将磷酸控制在 14-18 盎司/加仑(以 H3PO4 计)。

(7) Control the solution temperature at 160-180°F.

将溶液温度控制在 160-180 °F.

C. Parts Preparation

零件准备

(1) If the parts are oily or greasy, vapor degrease or solvent clean them per SOPM 20-30-03.

如果零件上有油污或油脂,则应按照 SOPM 20-30-03 进行蒸气脱脂或溶剂清洗。

(2) Remove or mask off all metals that are not magnesium. Make sure the masks are resistant to the solutions used in the procedure.

去除或遮盖所有非镁金属。确保面罩可耐受程序中使用的溶液。

(3) Put the parts in the racks. Make sure the electrical connections are good.

将零件放入架子。确保电气连接良好。

(4) Remove oxides, scale, and contamination per BAC5769, Type 2.

按照 BAC5769 第 2 类清除氧化物、水垢和污染物。

D. Anodize with this procedure:

按此程序进行阳极氧化:

(1) Set the electrical controls to zero.

将电气控制设置为零。

(2) Put the parts into the solution with the power off.

关闭电源,将零件放入溶液中。

(3) Within 30 seconds, adjust the controls to 20 amps/sq. ft. (or the value found by tests for the alloy).

在 30 秒内,将控制器调至 20 安培/平方英尺(或合金测试发现的值)。

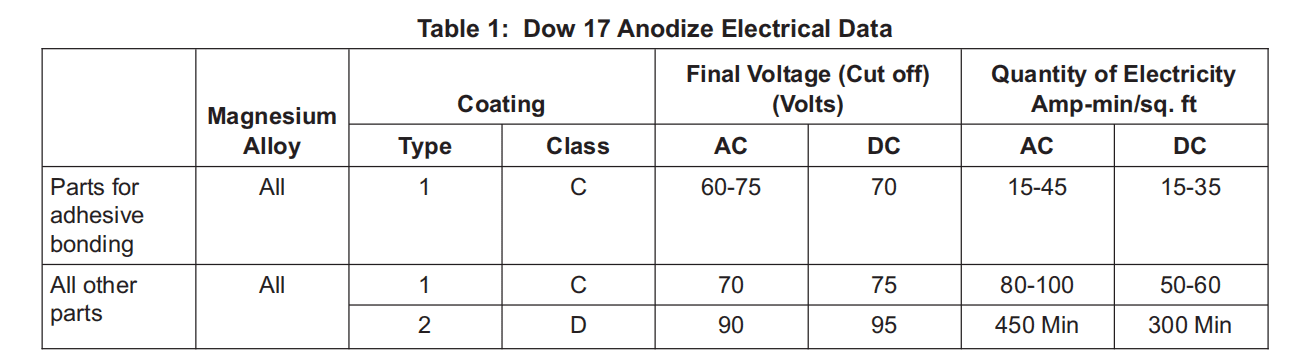

(4) As the coating forms, increase the voltage to keep the current density constant, until you get to the minimum cut-off voltage specified in Table 1. Then let the current decrease until the specified amp-minute/sq. ft. value is reached. The approximate total time at 20 amps/sq. ft. is 4-5 minutes (Type 1, Class C) or 20-25 minutes (Type 2, Class D).

当涂层形成时,增加电压以保持电流密度不变,直到达到表 1 规定的最小关闭电压。然后让电流减小,直到达到规定的安培分/平方英尺值。20 安培/平方英尺的总时间大约为 4-5 分钟(类型 1,C 级)或 20-25 分钟(类型 2,D 级)。

(5) Turn the current off at the correct time.

在正确的时间关闭电流。

(6) Remove the part from the solution within 45 seconds. Let the part drain into the anodizing tank for 1 minute before you move the part to the rinse tank.

在 45 秒内将零件从溶液中取出。让零件在阳极氧化槽中 1 分钟,然后再将零件移到冲洗槽中。

(7) Rinse with a cold water spray for 5-10 minutes. Or immersion rinse for 5-8 minutes. If you spray rinse the parts, make sure you hit all of the anodized surfaces and let the parts fully drain. Also, to prevent streaks, make sure you lower the load of parts fully into the rinse water before you start the spray.

用冷水喷淋冲洗 5-10 分钟。或浸泡冲洗 5-8 分钟。如果喷淋冲洗零件,应确保冲洗到所有阳极氧化表面,并让零件完全沥干。此外,为了防止出现条纹,在开始喷淋之前,确保将装载的零件完全放入冲洗水中。

(8) As an option to help dry the parts, rinse them in hot (120-160°F) water for a maximum of 3 minutes.

可以选择在热水(120-160 °F)中最多冲洗 3 分钟,以帮助擦干零件。

(9) Dry in air from room temperature to 180°F.

在室温至 180°F 的空气中烘干。

(10) Examine the anodize coating per Paragraph 4.C. Use only clean white gloves.

按照第 4.C 段检查阳极氧化涂层。只使用干净的白手套。

(11) Paint the part, or adhesive bond it, as specified by overhaul instructions, as quickly as possible. Keep the part clean and dry until painted or bonded.

按照大修说明的规定,尽快给零件上漆或粘接。在喷漆或粘接之前,保持零件清洁干燥。

E. Quality Control

质量控制

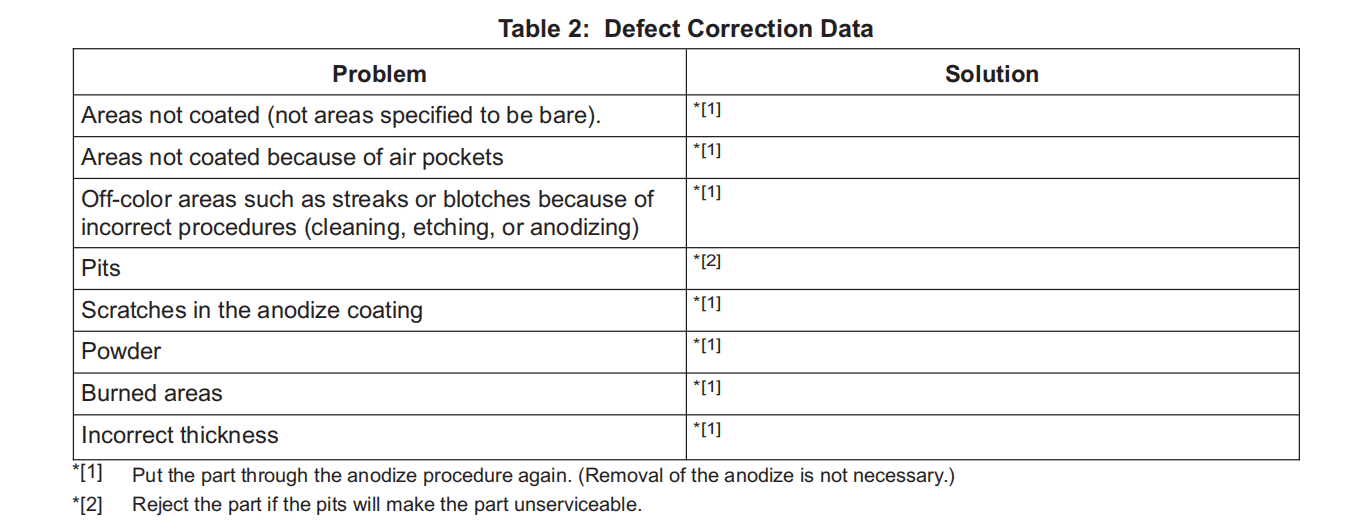

(1) The coating must be continuous over all the surface and have no powder, scratches, burrs or breaks (other than at electrical contact points). If you find defects, see Table 2.

涂层必须在整个表面上连续,没有粉末、划痕、毛刺或破损(电接触点除外)。如果发现缺陷,请参见表 2。

(2) The coating thickness on all parts which are to be adhesive bonded must be 0.0001-0.0002 inch. On other parts, thickness must be 0.00015-0.00070 inch (Type 1, Class C) or 0.00090-0.00160 inch (Type 2, Class D).

所有要粘接的零件的涂层厚度必须为 0.0001-0.0002 英寸。在其他零件上,厚度必须为 0.00015-0.00070 英寸(类型 1,C 级)或 0.00090-0.00160 英寸(类型 2,D 级)。

4. DOW 19 TOUCH-UP PROCESS DOW 19 修补程序

A. General

通用

(1) Until it dries, the coating is soft and easily rubbed off or damaged by swabs used to apply the coating, high pressure spray, or the full force of compressed air blast used to dry the parts.

在干燥之前,涂层是柔软的,很容易被用于涂抹涂层的棉签、高压喷涂或用于干燥零件的全力压缩空气喷射擦掉或损坏。

(2) Use distilled or deionized water for solution makeup.

使用蒸馏水或去离子水修补溶液。

B. Solution Makeup and Control

溶液修补和控制

(1) Fill a clean polyethylene or glass container to the 90 percent level with water.

在干净的聚乙烯或玻璃容器中注入 90% 的水。

(2) Slowly add 1-1/3 ounce chromic acid per gallon of final solution.

每加仑最终溶液缓慢加入 1-1/3 盎司铬酸。

(3) Add 1 ounce calcium sulfate per gallon of final solution.

每加仑最终溶液加入 1 盎司硫酸钙。

(4) Fill the task to the operating level with water.

注入水至操作水平。

(5) Stir with much force for 15 minutes to make sure that the solution is saturated with calcium sulfate.

用力搅拌 15 分钟,确保溶液中的硫酸钙达到饱和。

(6) Control the pH at 1.2-1.6 with sodium hydroxide or sulfuric acid as necessary.

必要时用氢氧化钠或硫酸将 pH 值控制在 1.2-1.6。

(7) Discard the solution when you are done with it.

溶液用完后报废。

C. Touch-Up Application

补涂(修饰、修整)

(1) Manually sand to blend the area smoothly into the adjacent good finish.

手工打磨,使该区域与邻近的良好饰面平滑融合。

(2) Remove all loose dust and particles with a soft bristle brush or a clean wiper.

用软毛刷或干净的抹布清除所有松散的灰尘和颗粒。

(3) Cold solvent alkaline clean per SOPM 20-30-03 to get a water break free surface. If water breaks do not go away, hand scrub with a water slurry of magnesium oxide.

按照 SOPM 20-30-03 标准进行冷溶剂碱性清洁,使表面无断水。如果水渍仍未消除,则用氧化镁水浆手工擦洗。

(4) Apply the Dow 19 solution with a swab until the metal surface becomes dull golden to dark brown in color. Be careful, because you could rub away the coating. As you use the solution, remove suspended material from it. Frequently apply large quantities of clean new full-strength solution, and discard runoff, because the chemicals quickly become weak as they react with the magnesium surface.

用棉签涂抹 Dow 19 溶液,直到金属表面变成暗金色至深褐色。要小心,因为可能会擦掉涂层。在使用溶液时,要清除其中的悬浮物。经常使用大量干净的新的全浓度溶液,并丢弃流出的溶液,因为化学物质在与镁表面发生反应后很快就会变弱。

(5) Rinse with cold water.

用冷水冲洗。

CAUTION :HIGH PRESSURE SPRAY OR THE FRICTION OF A WIPER WILL DAMAGE THE FRESH COATING.

注意:高压喷雾或擦拭布的摩擦会损坏新涂层。

(6) Dry with circulating air (room temperature to 180°F) or compressed air. Do not turn the full blast of the compressed air at the parts.

用循环空气(室温至 180 °F)或压缩空气吹干。不要将压缩空气全部对准零件。

(7) Apply primer or other coating as specified. Give parts protection from contamination until they are painted.

按照规定涂上底漆或其他涂层。保护零件免受污染,直至涂漆。

D. Quality Control

质量控制

(1) The coating must have no pits, striations, powder, scratches, uncoated areas or other defects.

涂层不得有凹坑、条纹、粉末、划痕、未涂层区域或其他缺陷。

(2) Defects which make the part unserviceable cannot be repaired.

使零件无法使用的缺陷不能修复。

(3) Wipe off powder with a clean cloth.

用干净的布擦掉粉末。

(4) Touch up uncoated areas and scratches per Paragraph 4.C., as necessary.

根据需要,按第 4.C 段的规定修补未涂层区域和划痕。

5. BMC DIP PROCESS 浸渍工艺

A. General

通用

(1) Until it dries, the coating is soft and easily rubbed off or damaged by agitation of dip solution, high pressure spray, or compressed air used to dry parts.

在干燥之前,涂层是软的,很容易被浸渍溶液的搅拌、高压喷雾或用于干燥零件的压缩空气擦掉或损坏。

(2) Use distilled or deionized water for solution makeup.

溶液修补使用蒸馏水或去离子水。

B. Solution Makeup and Control

溶液修补和控制

(1) Fill a cleaned tank to 75 percent of operating level with water.

将水注入清洗过的槽至工作水位的 75%。

(2) Slowly add 5 ounces sodium dichromate dihydrate per gallon of final solution.

每加仑最终溶液缓慢加入 5 盎司二水重铬酸钠。

(3) Add 0.5 ounce sodium sulfate per gallon of fuel solution.

每加仑燃料溶液加入 0.5 盎司硫酸钠。

(4) Fill to operating level with water.

加水至操作水平。

(5) Mix fully.

充分混合。

(6) Controls

控制

(a) Control the pH at 1.6-1.9 with chromic acid as necessary.

必要时用铬酸将 pH 值控制在 1.6-1.9。

(b) Agitate solution with filtered air. Keep the solution at 60-80°F.

用过滤空气搅拌溶液。溶液温度保持在 60-80°F。

(c) Discard the solution when the magnesium is more than 2.0 oz/gal.

当镁含量超过 2.0 oz/gal 时,报废溶液。

C. Coating Application

涂层应用

(1) Vapor degrease per SOPM 20-30-03. Let the parts fully dry.

根据 SOPM 20-30-03 进行蒸汽脱脂。让零件完全干燥。

(2) If the parts have faying surfaces, without the full protection of an organic finish or sealant, do not immersion clean.

如果零件表面是粘合的,没有有机涂层或密封剂的全面保护,则不要浸泡清洗。

(3) Alkaline clean and rinse per SOPM 20-30-03.

按照 SOPM 20-30-03 进行碱性清洁和冲洗。

(4) Soak the part in concentrated chromium-nitrate solution (BAC 5769, solution no. 2), for sufficient time to remove scale or corrosion plus one minute.

将零件浸泡在浓硝酸铬溶液(BAC 5769,2 号溶液)中,浸泡时间应足以除去水垢或锈蚀加一分钟。

(5) Cold water rinse 8-10 minutes. Immersion rinse is preferred; spray rinse is optional.

冷水冲洗 8-10 分钟。首选浸泡冲洗;可选择喷淋冲洗。

(6) Soak the parts in the BMC solution (Paragraph 4.B.) for 3-10 minutes. Adjust this time as necessary to get a dull golden to dark brown coating.

将零件浸泡在 BMC 溶液(第 4.B 段)中 3-10 分钟。根据需要调整时间,以获得暗金色至深棕色的涂层。

(7) Rinse in cold water. Immersion rinse of 3 minutes is preferred; 3-5 minute spray rinse is optional.

用冷水冲洗。最好浸泡冲洗 3 分钟;可选择喷淋冲洗 3-5 分钟。

(8) Dry with a good flow of 60-180°F air, or compressed air.

用 60-180 °F 的良好气流或压缩空气吹干。

(9) Apply the primer or other coating as specified by the overhaul instructions. Give the parts protection from contamination until they are painted.

按照大修说明的规定涂上底漆或其他涂层。在涂漆前保护零件免受污染。

D. Quality Control

质量控制

(1) The coating must have no pits, striations, powder, scratches, uncoated areas or other defects.

涂层不得有凹坑、条纹、粉末、划痕、未涂层区域或其他缺陷。

(2) Defects which make the part unserviceable cannot be repaired.

使零件无法使用的缺陷不能修复。

(3) Wipe away powder by wiping with a clean cloth.

用干净的布擦掉粉末。

(4) Touch up scratches and uncoated areas by the Dow 19 procedure per Paragraph 4.

按照第 4 段中 Dow 19 的程序修补划痕和未涂层区域。