Torque and Torque Wrenches

扭矩与扭矩扳手

As the speed of an aircraft increases, each structural member becomes more highly stressed. It is therefore extremely important that each member carry no more and no less than the load for which it was designed. To distribute the loads safely throughout a structure, it is necessary that proper torque be applied to all nuts, bolts, studs, and screws. Using the proper torque allows the structure to develop its designed strength and greatly reduces the possibility of failure due to fatigue.

随着飞机速度的增加,每个结构部件承受的应力也随之增大。因此,确保每个部件承受的载荷恰好等于其设计载荷至关重要。为将载荷安全地分布于整个结构中,必须对所有螺母、螺栓、螺柱和螺钉施加正确的扭矩。采用正确扭矩可使结构发挥设计强度,并大幅降低疲劳失效风险。

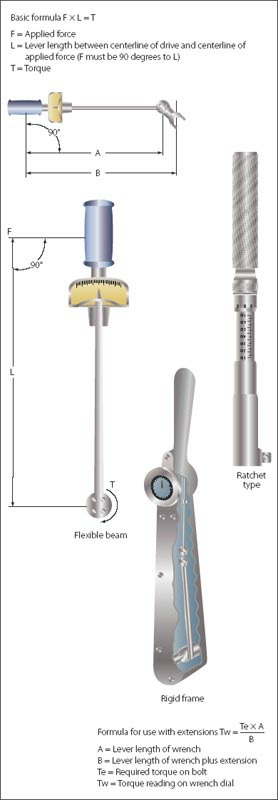

Torque wrenches. The three most commonly used torque wrenches are the flexible beam, rigid frame, and the ratchet types. [Figure 5-33] When using the flexible beam and the rigid frame torque wrenches, the torque value is read visually on a dial or scale mounted on the handle of the wrench.

扭矩扳手。最常用的三种扭矩扳手分别为柔性梁式、刚性框架式和棘轮式。[图5-33] 使用柔性梁式和刚性框架式扭矩扳手时,需通过扳手手柄上的刻度盘或量规目测读取扭矩值。

To use the ratchet type, unlock the grip and adjust the handle to the desired setting on the micrometer type scale, then relock the grip. Install the required socket or adapter to the square drive of the handle. Place the wrench assembly on the nut or bolt and pull the wrench assembly on the nut or bolt and pull in a clockwise direction with a smooth, steady motion. (A fast or jerky motion will result in an improperly torqued unit.) When the applied torque reaches the torque value indicated on the handle setting, the handle will automatically release or “break” and move freely for a short distance.

使用棘轮式扭矩扳手时,需先解锁手柄,将手柄调整至千分尺式刻度所需位置后重新锁定。将所需套筒或转接头安装至手柄方头驱动端。将扳手组件置于螺母或螺栓上,以顺时针方向平稳持续地施加扭矩。(快速或间断动作将导致扭矩值不准确。)当施加扭矩达到手柄设定值时,手柄会自动释放或“断开”,并短暂自由转动。

Figure 5-33. Common torque wrenches.

The release and free travel is easily felt, so there is no doubt about when the torquing process is completed.To assure getting the correct amount of torque on the fasteners, all torque wrenches must be tested at least once a month or more often if necessary.

松开和自由行程感明显,因此扭矩操作完成时毫无疑问。为确保紧固件获得正确扭矩值,所有扭矩扳手必须每月至少测试一次,必要时需更频繁检测。

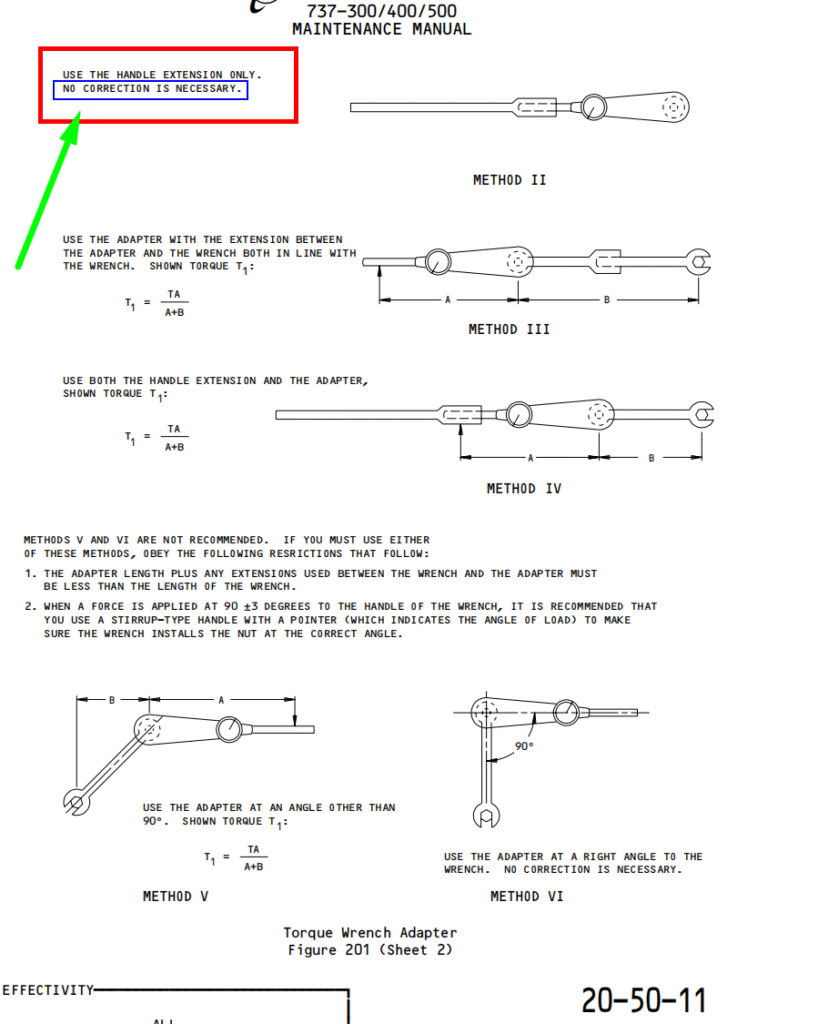

Note: It is not advisable to use a handle length extension on a flexible beam type torque wrench at any time. A handle extension alone has no effect on the reading of the other types. The use of a drive end extension on any type of torque wrench makes the use of the formula mandatory. When applying the formula, force must be applied to the handle of the torque wrench at the point from which the measurements were taken. If this is not done, the torque obtained will be incorrect.

注:柔性梁式扭矩扳手严禁使用手柄延长杆。其他类型扳手使用延长杆不影响读数。任何类型扭矩扳手使用驱动端延长杆时,必须应用计算公式。应用公式时,必须在扭矩扳手测量点施加作用力于手柄。否则所得扭矩值将不准确。

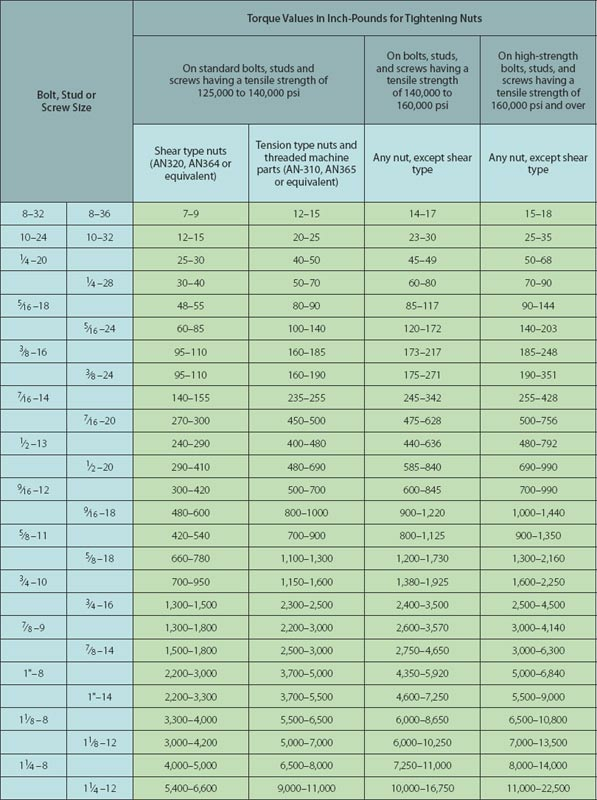

Torque Tables. Use the standard torque table as a guide in tightening nuts, studs, bolts, and screws whenever specific torque values are not called out in maintenance procedures. The following rules apply for correct use of the torque table: [Figure 5-34]

扭矩表。当维护程序未指定具体扭矩值时,紧固螺母、螺柱、螺栓及螺钉均应参照标准扭矩表。正确使用扭矩表需遵循以下规则:[图5-34]

- To obtain values in foot-pounds, divide inch-pounds by 12.

要获得英尺磅单位的数值,请将英寸磅除以12。

- Do not lubricate nuts or bolts except for corrosion-resistant steel parts or where specifically instructed to do so.

除防腐蚀钢零件(不锈钢零件)或有特殊指示的情况外,请勿对螺母或螺栓进行润滑。

- Always tighten by rotating the nut first if possible. When space considerations make it necessary to tighten by rotating the bolt head, approach the high side of the indicated torque range. Do not exceed the maximum allowable torque value.

紧固时应优先旋转螺母操作。若因空间限制必须旋转螺栓头部紧固,请尽量采用扭矩范围上限值进行操作,切勿超过最大允许扭矩值。

- Maximum torque ranges should be used only when materials and surfaces being joined are of sufficient thickness, area, and strength to resist breaking, warping, or other damage.

最大扭矩范围仅适用于被连接材料及表面具备足够厚度、面积和强度,可抵抗断裂、变形或其他损伤的情况。

- For corrosion resisting steel nuts, use torque values given for shear type nuts.

耐腐蚀钢制螺母应采用剪切型螺母的扭矩值。

- The use of any type of drive end extension on a torque wrench changes the dial reading required to obtain the actual values indicated in the standard torque range tables. When using a drive end extension, the torque wrench reading must be computed by use of the proper formula, which is included in the handbook accompanying the torque wrench.

扭矩扳手加装任何类型驱动端延长杆时,需通过专用公式计算实际扭矩值(标准扭矩范围表所示数值),该公式详见扭矩扳手随附手册。

Figure 5-34. Standard torque table (inch-pounds)

Torque Wrench

扭力扳手

There are times when definite pressure must be applied to a nut or bolt as it is installed. In such cases, a torque wrench must be used. The torque wrench is a precision tool consisting of a torque indicating handle and appropriate adapter or attachments. It measures the amount of turning or twisting force applied to a nut, bolt, or screw.

在安装螺母或螺栓时,有时必须施加特定的压力。这种情况下必须使用扭力扳手。扭力扳手是一种精密工具,由扭矩指示手柄和相应的适配器或附件组成。它用于测量施加在螺母、螺栓或螺钉上的旋转或扭转力矩。

Before each use, the torque wrench should be visually inspected for damage. If a bent pointer, cracked or broken glass (dial type), or signs of rough handling are found, the wrench must be tested. Torque wrenches must be tested at periodic intervals to ensure accuracy.

每次使用前,应目视检查扭力扳手是否有损坏。若发现指针弯曲、玻璃破裂(指针式)或粗暴操作痕迹,必须对扳手进行测试。扭力扳手必须定期测试以确保精度。

Calibrating a torque wrench is the process in which the manufacturers of the torque wrench set ensure a precise torque occurs on a standard and consistent basis. Regular torque wrench calibration ensures repeatable accuracy and adherence to standards. A torque wrench is a precision tool and should be treated and maintained like a delicate measuring instrument. A torque wrench must be properly calibrated and maintained on a preventative maintenance and calibration schedule. In order to maintain accuracy, it is crucial that a torque wrench and other measuring equipment be calibrated regularly. Some wrenches or tools may recommend six (6) month calibration intervals, while others may schedule it at twelve (12) months.

扭力扳手的校准是制造商确保其在标准条件下持续产生精确扭矩的过程。定期校准可保障重复精度并符合标准规范要求。扭力扳手属于精密工具,应如精密测量仪器般精心维护。必须依据预防性维护与校准计划进行规范校准与保养。为维持精度,扭力扳手及其他测量设备必须定期校准。部分扳手或工具建议每6个月校准一次,另一些则安排为每12个月一次。

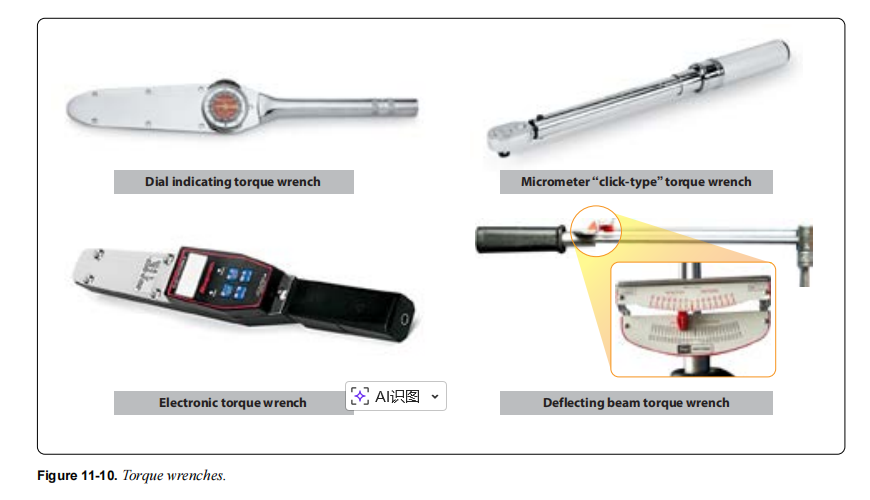

Commonly used torque wrenches include the deflecting beam (not shown), dial indicating, micrometer, and electronic setting types. [Figure 11-10] When using the deflecting beam and the dial indicating torque wrenches, the torque is read visually on a dial or scale mounted on the handle of the wrench. The micrometer setting torque wrench is preset to the desired torque. When this torque is reached, the operator notices a sharp impulse or breakaway “click.”

常用的力矩扳手类型分别为:弯曲梁式、指针式和千分尺和电子设定式。[图11-10]使用弯曲梁式和指针式扭矩扳手时,需通过扳手手柄上的刻度盘或量规目视读取扭矩值。千分表式扭矩扳手预设目标扭矩值,当达到设定扭矩时,操作者会感知到明显的冲击感或脱扣“咔嗒”声。

拓展1:手柄加长是否影响力矩??

拓展2:开口销孔对齐

Cotter Pin Hole Line Up

开口销孔对齐

When tightening castellated nuts on bolts, the cotter pin holes may not line up with the slots in the nuts for the range of recommended values. Except in cases of highly stressed engine parts, the nut may not be over torque. Remove hardware and realign the holes. The torque loads specified may be used for all unlubricated cadmiumplated steel nuts of the fine or coarse thread series which have approximately equal number of threads and equal face bearing areas. These values do not apply where special torque requirements are specified in the maintenance manual.

紧固螺栓上的带槽螺母时,开口销孔可能无法与螺母槽口在推荐扭矩范围内对齐。除高应力发动机零件外,螺母扭矩不得超标。拆卸紧固件并重新对齐孔位。所规定的扭矩负荷值适用于所有未润滑的镀镉钢制螺母(细牙或粗牙系列),前提是螺纹数量大致相等且端面承压面积相同。若维护手册中规定了特殊扭矩要求,则这些值不适用。

If the head end, rather than the nut, must be turned in the tightening operation, maximum torque values may be increased by an amount equal to shank friction,provided the latter is first measured by a torque wrench.

若紧固操作中需旋转头部而非螺母,可将最大扭矩值增加相当于螺杆摩擦阻力的数值——前提是该阻力需事先通过扭矩扳手进行测量。(这个应该是对螺栓打力矩,最终力矩=螺栓的摩擦力矩+螺母的力矩????)

暂无评论内容