Cleaning Process for Boeing Oxygen System Components–Standard Practice Manual丨波音氧气系统部件清洁工艺–标准操作手册

TABLE OF CONTENTS

CLEANING PROCESS

1. Scope

2. General Recommendations

3. List of Abbreviations and Conversion Factors

4. Preliminary Cleaning Information

5. Pre-Cleaning

6. Miscellaneous Parts Cleaning

7 Visual Cleanliness Inspection

8. Nonvolatile Residue (NVR) Determination

9. Blank Sample Test

10. Particulate Sampling of Cleaned Detail Parts

11. Packaging for Oxygen Cleanliness

EXAMPLE FORMS

A INSPECTION DATA SHEET

B NONVOLATILE RESIDUE TEST REPORT

C CONTAMINATION ANALYSIS REPORT

APPENDIX A Cleaning Process for Transducers

APPENDIX B Use of Isopropyl Alcohol in Cleaning Processes

清洁流程

1.范围

2.一般建议

3.缩写和换算列表

4.初步清洁信息

5.预清洁步骤

6.其他部件清洁

7.视觉清洁检查

8.非挥发性残留物(NVR)测定

9.空白样品测试

10.清洁详细部件的颗粒采样

11.氧气清洁包装

示例表格

A检查数据表

B非挥发性残留物测试报告

C污染分析报告

附录A:传感器清洁流程

附录B:清洁过程中异丙醇的使用

CLEANING PROCESS清洁程序

1. Scope 范围

This document defines the cleanliness, packaging, marking, and inspection requirements for Boeing oxygen systems and components. When necessary, deviations from this specification to meet special situations or requirements may be mutually agreed upon by Carleton and Boeing. A list of Special Tools and Equipment is also included as well as a list of Consumable Materials required to perform cleaning procedures.

本文件规定了波音公司氧气系统和部件的清洁、包装、标记和检查要求。在必要时,卡尔顿公司和波音公司可就为满足特殊情况或要求而偏离本规范的情况达成一致。还包含特殊工具和设备清单以及执行清洁程序所需的消耗材料清单。

NOTE: Complete disassembly of the unit, including discarding all soft goods, in accordance with the applicable Component Maintenance Manual (CMM) is required prior to cleaning of parts.

注意:在清洁部件之前,需要按照适用的部件维护手册(CMM)对部件进行完全分解,包括丢弃所有软质物品。

1.1 Classification

分类

The following designations are provided for oxygen system components. A component may consist of parts classified to different categories based upon the oxygen pressure to which a part(s) surface is exposed.

氧气系统组件的命名如下。一个组件可能由根据部件表面暴露的氧气压力分类的不同类别的部件组成。

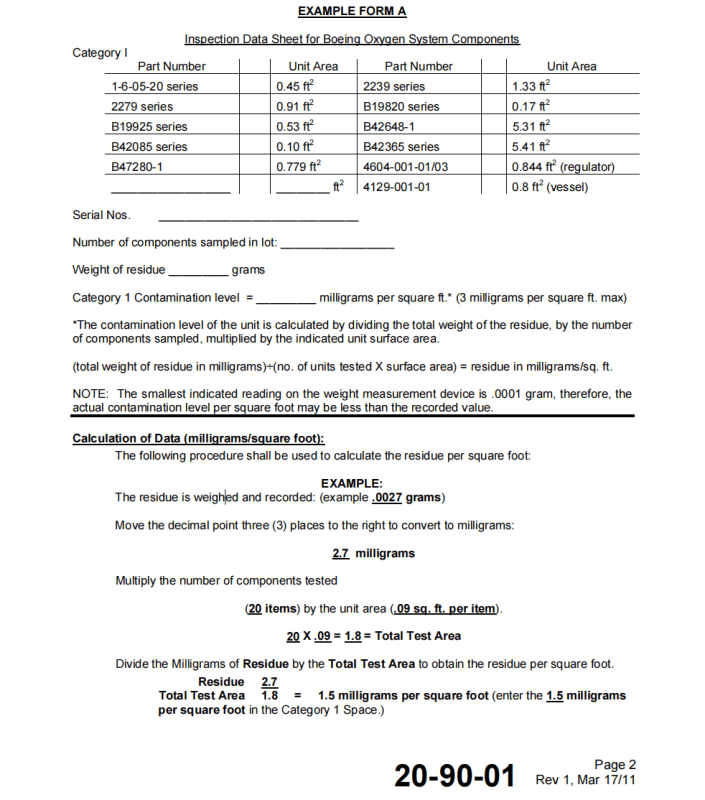

Category 1 – Components exposed to oxygen at pressures over 10 psi. Clean all component surfaces in direct contact with oxygen to a maximum of 3 milligrams of hydrocarbons and particulate residue, per square foot of surface area (see Example Form A).

第1类-暴露在压力超过10 psi的氧气中的组件。根据每平方英尺的表面面积,将所有直接接触氧气的组件表面清洁至最多3毫克碳氢化合物和颗粒残留物(参见示例表格A)。

NOTE: A practical way to meet the Category 1 requirement of 3 milligrams per square foot of surface area is to completely immerse all metallic parts (except transducers) in cleaning solution in accordance with this Standard Practice Manual.

注:满足每平方英尺表面面积3毫克的第1类要求的一种实用方法是,按照本标准操作手册的要求,将所有金属部件(除传感器外)完全浸入清洁溶液中。

Category 2 – Components exposed to oxygen at pressures up to and including 10 psi. Clean all component surfaces in direct contact with oxygen to produce visibly clean surfaces.

第2类-暴露在压力不超过10 psi的氧气中的组件。清洁所有直接接触氧气的组件表面,以产生可见的清洁表面。

![图片[1]-SPM 20-90-01波音氧气系统部件清洁工艺(Cobham)-航修札记](https://www.aeroacm.com/wp-content/uploads/2025/08/word-image-8646-1.png)

2. General Recommendations 一般建议

The following conditions are strongly recommended for the cleaning area.

强烈建议清洁区域满足以下条件。

A. Cleaning processes should be conducted in a Class 100,000 area maintained at a positive pressure, relative to surrounding areas and the outside of the building. Pressurized air should be drawn into the room through a series of filters which are inspected (at a minimum) every 3 months and changed as required.

清洁过程应在10万级区域进行,相对于周围区域和建筑物外部保持正压。加压空气应通过一系列过滤器吸入房间,过滤器至少每三个月检查一次,并根据需要更换。

B. The interior of the laminar flow workstations should be maintained at a class 10,000 level. The maximum number of 5 micron and larger particles per cubic foot should not exceed 65, and 0.5 micron size particles at less than 10,000.

层流工作站的内部应保持在10000级。每立方英尺中5微米及以上的颗粒的最大数量不得超过65个,小于10000个的0.5微米尺寸颗粒不得超过65个。

C. All paperwork required in the laminar flow work-station should be enclosed in poly film. Pull-out work tables should be provided at each laminar work bench. These tables are to be used for recording data, stamping, etc.

层流工作台内所有需要的文件资料均应采用聚乙烯薄膜进行包裹,每个层流工作台应配备可拉出式工作台,用于记录数据、盖章等。

D. All tools, fixtures, test setups, etc., being placed under the Class 10,000 laminar flow stations, should be cleaned to meet the cleanliness levels specified in this document.

放置在10,000级层流站下的所有工具、固定装置、测试设置等,应进行清洁以满足本文件规定的洁净度水平。

E. A supply of lint-free cloths should be provided for cleaning. Soiled cloths should be properly disposed of after use.

应提供无绒布料用于清洁,使用后的污布料应妥善处理。

F. No abrasive material such as steel wool, sandpaper, crocus cloth, or equivalent items used for cutting, grinding, filing, should be permitted.

不得使用钢丝绒、砂纸、番红花布或等同物品等磨削、研磨、锉削的磨料。

G. Smoking, eating, drinking, and storage of food should be prohibited in the Assembly and Test Class 100,000 and 10,000 Areas.

在组装和试验级别100,000和10,000区域内,应禁止吸烟、饮食和储存食物。

H. The windows and doors should (at minimum) be cleaned monthly.

门窗至少每月清洁一次。

I. An airborne particulate monitoring test should be conducted weekly, in each workstation, under normal working conditions. In the event that a workstation does not conform to the airborne particle monitoring test, the station should be recleaned using a lint-free cloth saturated with isopropyl alcohol (or equivalent), and flow retested.

在正常工作条件下,每个工作站每周进行一次空气微粒监测试验。如果某个工作站不符合空气微粒监测试验,则应使用浸有异丙醇(或等效物)的无绒布重新清洁该工作站,并重新进行流量试验。

J. Personnel entering the cleanliness verification area should wear the following:

进入洁净度验证区域的人员应穿戴以下防护装置:

1. Long-sleeved lint-free smocks, securely fastened at the front, neck and wrist. The smock should be changed weekly (minimum) or more frequently, as required.

长袖无绒围裙,前襟、颈部和手腕处牢固固定。围裙应每周更换一次(至少),或根据需要更频繁地更换。

2. Cleanroom hood (including face/beard cover).

洁净室罩(包括面罩/胡须罩)。

3. Lint free gloves (approved fabric or elastomer).

无绒手套(经批准的织物或弹性体)。

K. The following tasks should be performed in the cleanliness verification area:

应在清洁度验证区域执行以下任务:

1. Final flushing of parts or assemblies

零件或组件的最终冲洗

2. Non-Volatile Residue (NVR) testing

非挥发性残留物(NVR)检测

3. Particulate sampling of cleaned parts or assemblies

对清洁后的零件或组件进行微粒采样

4. Counting of the particulate samples

微粒样品计数

5. Packaging of cleaned/tested and accepted items

清洁/测试和验收物品的包装

6. “Black Light” cleanliness verification

黑色光清洁度验证

3. List of Abbreviations and Conversion Factors 缩略语和换算系数列表

![图片[2]-SPM 20-90-01波音氧气系统部件清洁工艺(Cobham)-航修札记](https://www.aeroacm.com/wp-content/uploads/2025/08/word-image-8646-2.png)

4. Preliminary Cleaning Information 初步清洁信息

A. Reason for Job

工作原因

CAUTION: BEFORE CLEANING, THE UNIT SHALL BE DISASSEMBLED IN ACCORDANCE WITH APPROPRIATE DISASSEMBLY PROCEDURES. CLEANING SHALL BE PERFORMED AT THE PIECE PART LEVEL ONLY.

注意:清洁前,应按照适当的拆卸程序拆卸设备。仅可在零件级别进行清洁。

CAUTION: CLEANING SHALL BE IN ACCORDANCE WITH BPS-O-100 UNLESS OTHERWISE SPECIFIED.

注意:清洁应符合BPS-O-100,除非另有规定。

The oxygen assemblies and components are used in high-pressure oxygen systems aboard commercial aircraft. Due to the danger of fire in such a system resulting from internal contamination, it is critical that oxygen system components be cleaned to a level that renders them safe for use in a high-pressure oxygen environment.

氧组件和部件用于商用飞机上的高压氧系统。由于此类系统中的内部污染会造成危险,因此氧系统组件必须清洁到使其在高压氧环境中使用是安全的水平。

NOTE: If the appropriate level of cleanliness cannot be achieved or maintained within the repair/overhaul facility handling this unit, it is STRONGLY RECOMMENDED that all servicing be referred back to the original manufacturer.

注:如果处理该装置的维修/检修机构无法达到或保持适当的清洁度,则强烈建议将所有维修工作交还给原始制造商。

WARNING: FAILURE TO USE SUITABLE EYE PROTECTION DURING CLEANING PROCEDURES MAY CAUSE INJURY TO THE EYES. WHEN USING CLEANING SOLVENTS AVOID PROLONGED OR REPEATED CONTACT WITH SKIN AND INHALATION OF TOXIC VAPORS OR SERIOUS INJURY MAY OCCUR. MAKE SURE THAT CLEANING PROCEDURES ARE PERFORMED IN AN APPROVED CLEANING CABINET, OR IN A WELL-VENTILATED ROOM OR AREA, OR SERIOUS PERSONAL INJURY MAY OCCUR. DO NOT USE SOLVENTS NEAR OPEN FLAMES, OR IN AREAS WHERE THERE ARE HIGH TEMPERATURES, OR SERIOUS PERSONAL INJURY, FIRE OR EXPLOSION MAY OCCUR. DO NOT ALLOW OIL, GREASE, FLAMMABLE SOLVENTS OR OTHER COMBUSTIBLE MATERIALS TO COME IN CONTACT WITH PARTS THAT WILL BE EXPOSED TO PRESSURIZED OXYGEN. DUST, LINT, AND FINE METAL PARTICLES ARE ALSO POTENTIAL COMBUSTIBLES THAT CAN IGNITE, AND RESULT IN EXPLOSION OR FIRE, WHEN EXPOSED TO PRESSURIZED OXYGEN. REFER TO AND FOLLOW APPLICABLE MANUFACTURER’S OR SUPPLIER’S MATERIAL SAFETY DATA SHEET (MSDS) BEFORE USING CLEANING MATERIALS SPECIFIED IN THIS PROCEDURE OR SERIOUS PERSONAL INJURY MAY OCCUR.

警告:清洁过程中未使用适当眼部防护装置可能导致眼睛受伤。使用清洁溶剂时,避免长时间或反复接触皮肤及吸入有毒蒸气,否则可能造成严重伤害。请确保清洁操作在经批准的清洗柜内进行,或在通风良好的房间/区域进行,否则可能导致严重人身伤害。切勿在明火附近或高温区域使用溶剂,否则可能发生严重人身伤害、火灾或爆炸。禁止让油污、油脂、易燃溶剂或其他可燃物质接触将暴露于加压氧气的部件。粉尘、棉绒和细小金属颗粒也是潜在可燃物,接触加压氧气后可能引发火灾或爆炸。使用本程序指定的清洁材料前,请务必查阅并遵循制造商或供应商提供的材料安全数据表(MSDS),否则可能导致严重人身伤害。

B. Job Set-up Information

作业设置信息

(1) Reference Documents

参考文件

![图片[3]-SPM 20-90-01波音氧气系统部件清洁工艺(Cobham)-航修札记](https://www.aeroacm.com/wp-content/uploads/2025/08/word-image-8646-3.png)

(2) Special Tools, Fixtures and Equipment

专用工具、夹具和设备

Special tools, fixtures and equipment necessary for cleaning in accordance with BPS-O-100 must be cleaned for oxygen service before use. Cleaning equipment must be capable of cleaning the unit to a nonvolatile residue (NVR) level equal to or less than 3 milligrams (mg) per square foot. Equivalent equipment and/or materials may be substituted.

根据BPS-O-100要求进行清洁所需的专用工具、夹具和设备在使用前必须进行氧气服务清洁。清洁设备必须能够将装置的非挥发性残留物(NVR)水平清洁到等于或小于每平方英尺3毫克(mg)。可采用等效的设备和/或材料代替。

![图片[4]-SPM 20-90-01波音氧气系统部件清洁工艺(Cobham)-航修札记](https://www.aeroacm.com/wp-content/uploads/2025/08/word-image-8646-4.png)

![图片[5]-SPM 20-90-01波音氧气系统部件清洁工艺(Cobham)-航修札记](https://www.aeroacm.com/wp-content/uploads/2025/08/image-49-837x1024.png)

(3) Consumable Cleaning Materials

可消耗的清洁材料

International environmental agreements may limit the use of some consumable cleaning materials. Equivalent materials may be substituted.

国际环境协议可能会限制某些消耗性清洁材料的使用,可采用同等材料代替。

5. Pre-cleaning 预清洗

CAUTION: EXERCISE CARE WHEN HANDLING, LOADING AND PROCESSING PARTS THROUGH ALL CLEANING OPERATIONS. PARTS SHOULD BE PROCESSED IN WAYS THAT PREVENT CRITICAL FEATURES FROM BEING DAMAGED DURING CLEANING.

注意:在通过所有清洁操作处理、装载和加工零件时,应小心谨慎。零件的加工方式应能防止关键特征在清洁过程中受损。

Pre-cleaning shall consist of the removal of undesirable or excessive contamination and visual inspection.

预清洗应包括去除不良或过度的污染物和目视检查。

A. Preparation:

准备:

– Visually inspect all parts and remove tape, stickers, labels and adhesive residues. Aqueous cleaner solution of cleaning agent and deionized water shall be replaced daily or more frequently when visibly contaminated. The mix concentration shall be approximately 1 ounce (30 cc) of cleaning agent per gallon of deionized water.

-目视检查所有零件,去除胶带、贴纸、标签和粘合剂残留。每天更换清洁剂和去离子水的水溶液,如果明显污染,则更频繁地更换。混合浓度应为每加仑去离子水约1盎司(30 cc)清洁剂。

B. Pre-cleaning

预清洗

– Pre-cleaning shall include the removal of chips, corrosion, slag, burrs, preservatives, and similar foreign materials. Appropriate methods of removal shall apply and. As required, use aqueous cleaner solution or isopropyl alcohol, hand wash, scrub, or flush, using appropriate brushes, swabs, or other applicable tools.

-预清洗应包括去除切屑、腐蚀、渣滓、毛刺、防腐剂和类似的异物。应采用适当的去除方法,必要时使用水性清洁剂溶液或异丙醇、洗手液、擦洗、冲洗,使用适当的刷子、棉签或其他适用工具。

C. Inspection

检查

– While performing this operation, the operator is to inspect threads, the intersection of bores and drilled passages, blind holes, undercut features, and all visible surfaces for hanging burrs or jagged edges. Suspect items/parts shall be segregated from the order and properly dispositioned.

-在执行该操作时,操作员应检查螺纹、孔与钻孔的交界处、盲孔、倒角特征以及所有可见表面是否存在悬挂毛刺或锯齿状边缘。可疑物品/零件应从订单中分离并妥善处置。

6. Miscellaneous Parts Cleaning 杂项零件清洗

A. Equipment Temperature Parameters:

设备温度参数

![图片[6]-SPM 20-90-01波音氧气系统部件清洁工艺(Cobham)-航修札记](https://www.aeroacm.com/wp-content/uploads/2025/08/word-image-8646-6.png)

B. Cleaning Solution Preparation

清洗液制备

WARNING: METEX™ TS-40A AND TURCO® ARE ALKALINE MATERIALS. PROTECT YOUR EYES AND SKIN AND AVOID INHALATION OF POWDER DURING MAKE UP OPERATION. WEAR GOGGLES OR FACE SHIELD, DUST MASK, AND PROTECTIVE CLOTHING. FLUSH EXPOSED AREAS WITH CLEAN COLD WATER. CONSULT A PHYSICIAN IN CASE OF INJURY.

警告:METEX™TS-40A和TURCO®是碱性材料。在制作操作过程中,请保护眼睛和皮肤,避免吸入粉末。请佩戴护目镜或面罩、防尘口罩和防护服。用清洁的冷水冲洗暴露部位。如受伤,请咨询医生。

Initial cleaner solution mixture shall be prepared by filling the wash tank with de ionized water. Activate the heater system until the water reaches the approximate operating temperature. Turn on the ultrasonics and slowly add 1 ounce (30 cc) of Turco® or Metex™ powder, per each gallon (4 liters) of deionized water. Allow 5 minutes minimum for thorough mixing.

初始清洁溶液混合物的制备方法是:向洗涤槽中注入去离子水。启动加热系统,直至水温达到近似工作温度。打开超声波发生器,并根据每加仑(4升)去离子水的量,缓慢加入1盎司(30毫升)Turco®或Metex™粉末。至少需要5分钟时间来充分混合。

C. Controls:

控制

Solution concentration shall be verified using the appropriate Turco® or Metex™ test kit and the titration method. Record concentration measurement on process control chart. Add cleaner or water as required to maintain proper concentration. Allow five minutes for stabilization after adding cleaner or water to the solution.

溶液浓度应使用适当的Turco®或Metex™检测试剂盒和滴定法进行验证。在过程控制图上记录浓度测量值。根据需要添加清洁剂或水以保持适当的浓度。向溶液中添加清洁剂或水后,静置5分钟以稳定。

D. Cleaning (Station #1)

清洗 (Station #1)

NOTE: Parts with special surface treatments such as electrofilm shall not be placed in the detergent ultrasonic. The parts may be hand agitated or swished in the detergent solution, without ultrasonics, and at medium heat (115 – 125°F, 46 – 52°C).

注:带有特殊表面处理的零件,如电膜等,不得放入清洗液超声波清洗机中。可将零件在清洗液中用手搅拌或晃动,但不进行超声波清洗,并保持中温(115-125°F,46-52°C)。

CAUTION: TRANSDUCERS CANNOT BE SUBMERGED. SEE APPENDIX A FOR CLEANING PROCEDURES SPECIFIC TO TRANSDUCERS.

注意:传感器不能浸入水中。有关传感器的清洁程序,请参见附录A。

When loading parts into the cleaning system basket, parts with blind holes or cavities should be oriented to eliminate air locks and to ensure that all surfaces are covered by the ultrasonic action. Submerge basket in cleaning tank and verify all of the parts to be cleaned are totally submerged. Turn on ultrasonics for a time period of not less than 4 minutes, or greater than 6 minutes. Turn off the ultrasonics. Turn on the sparger and allow to flow for 15 seconds minimum. Turn off the sparger and raise the basket above the cleaner. Suspend over the cleaner for 10 seconds minimum to allow residual cleaner to drip/drain into tank. Immediately proceed to rinse operation. The Pre-Rinse operation must be performed within 1 minute of removal of parts from the cleaner.

在将零件装入清洗系统篮筐时,带有盲孔或空腔的零件需调整方向以消除气锁现象,并确保所有表面都能被超声波作用覆盖。将篮筐浸入清洗槽中,确认待清洗零件完全浸没。开启超声波清洗功能至少4分钟(建议6分钟以上),随后关闭超声波。启动喷淋器并持续运行至少15秒,之后关闭喷淋器并将篮筐抬升至清洗槽上方。让篮筐悬停于清洗槽上方至少10秒,使残留清洁剂滴落至槽内。立即进行冲洗操作。预冲洗步骤必须在零件取出后1分钟内完成。

E. Pre-Rinse (Stations #2 and #3)

预冲洗(Stations #2 and #3)

Place parts rack into ambient temperature de ionized water rinse station #1 for a minimum of 30 seconds. Place parts rack into rinse station #2 for a minimum of 30 seconds while alternately raising and lowering the basket to provide agitation. The Final Rinse operation (step F) must be performed within 1 minute of removal of parts from the pre-rinse.

将零件架放入环境温度的去离子水中,冲洗站#1至少冲洗30秒。将零件架放入冲洗站#2,交替升降篮筐以提供搅拌,至少冲洗30秒。最终冲洗操作(步骤F)必须在从预冲洗中取出零件后1分钟内完成。

F. Final Rinse (Station #4)

最终冲洗(Station #4)

Submerge basket in final rinse tank and verify all of the parts are totally submerged. Turn on ultrasonics for a time period of not less than 3 minutes (additional time may be needed for unusually shaped items). Turn off the ultrasonics and raise the basket out of the final rinse. Suspend over the rinse tank for 10 seconds minimum to allow water to drip/drain into tank. Immediately proceed to drying operation.

将浸没篮放入最终冲洗槽,确认所有部件完全浸没。开启超声波清洗机,持续运行至少3分钟(对于形状特殊的产品可能需要延长时间)。关闭超声波后提起浸没篮脱离冲洗槽。悬挂在冲洗槽上方至少10秒,使水分自然滴落排出。立即启动干燥程序。

G. Drying (Station #5)

干燥(Station #5)

Place rack into dryer and close lid. Dry at 140 – 160°F (60 – 71°C) for a minimum of 10 minutes. Complex shapes and ports in items may require additional time. Adjust time and temperature to provide adequate drying of parts being processed. Remove parts from drying station and position at the load station.

将架子放入干燥器,关闭盖子。在140-160°F(60-71°C)温度下干燥至少10分钟。若物品存在复杂形状或接口结构,可能需要延长干燥时间。请根据加工件的具体情况调整干燥时间和温度参数,确保充分干燥。取出待干燥部件后,将其移至装载工位(站)。

NOTE: Blow dry using dry nitrogen, while parts are at an elevated temperature, to expedite thorough drying.

注:当部件处于高温状态时,请使用干燥氮气进行吹风干燥,以加速彻底干燥过程。

(Option): To facilitate drying after final rinse, parts may be momentarily sprayed, dipped or flushed, using clean isopropyl alcohol. Blow dry using dry nitrogen.

(选项):为便于最终冲洗后的干燥,可使用洁净的异丙醇对部件进行瞬时喷淋、浸没或冲洗。用干燥的氮气吹干。

H. Inspection and Packaging, Standard Process

检查和包装,标准流程

Visually examine all accessible surfaces in accordance with Section 7. Rejected items shall be re-cleaned and retested. Place parts on tray, petri dishes, or in heat-sealed poly bags. All containers must be cleaned to a level necessary to protect the cleanliness of the parts. Label package “Cleaned for Oxygen Service”.

根据第7节的要求,目视检查所有可接触表面。被拒收的物品应重新清洁并重新测试。将部件放在托盘、培养皿或热封聚乙烯袋中。所有容器必须清洁到足以保护部件清洁度的程度。在包装上贴上“Cleaned for Oxygen Service”的标签。

7. Visual Cleanliness Inspection – White Light and Ultraviolet Light Source 目视清洁度检查-白光和紫外光源

A. Using a 100 foot-candle power (minimum) light source, visually examine all accessible surfaces for objectionable matter that can be seen with the unaided ye (approximately 50 microns or larger in size). All parts shall be subjected to this examination. Visible material is cause for rejection.

使用100英尺烛光功率(最小)光源,目视检查所有可接触表面是否存在肉眼可见的不良物质(尺寸约50微米或更大)。所有部件均应接受此检查。可见材料是导致拒收的原因。

B. Visually examine all accessible surfaces for presence of petroleum type hydrocarbons and fluorescent materials with ultraviolet (black light) source. Visible material is cause for rejection.

使用紫外(黑光)光源,目视检查所有可接触表面是否存在石油类碳氢化合物和荧光材料。可见材料会导致拒收。

C. Re-clean as required based on results of visual examination. Visible material is cause for rejection.

根据目视检查结果,按要求重新清洁。可见材料是导致拒收的原因。

8. Nonvolatile Residue (NVR) Determination 非挥发性残留物(NVR)测定

The nonvolatile residue test is conducted on the basis of 100 ml of isopropyl alcohol per square foot. If the area is less than a square foot, it shall be left up to the discretion of the operator as to the sampling size. A minimum of 100 ml shall be taken. The following levels apply per square foot of unit surface area.

非挥发性残留物试验以每平方英尺100毫升异丙醇为基准进行。如果面积小于一平方英尺,则应由操作人员自行决定取样量,但至少应取100毫升。以下各值适用于单位表面积的每平方英尺。

![图片[7]-SPM 20-90-01波音氧气系统部件清洁工艺(Cobham)-航修札记](https://www.aeroacm.com/wp-content/uploads/2025/08/word-image-8646-7.png)

A. All glassware/test containers shall be cleaned so that they have NVR levels equal to or less than 3 mg per square ft.

所有玻璃器皿/试验容器均应清洁,以使其NVR水平等于或小于3 mg/平方英尺。

B. A blank or comparative sample test, of the isopropyl alcohol being used, shall be performed, and data recorded, in accordance with Section 9.

应按照第9节的要求,对所用异丙醇进行空白或对照样品试验,并记录数据。

C. Absolutely no parts shall be flushed unless they have undergone (as a minimum) cleaning in accordance with the Sections 5, 6, and 7.

绝对不能冲洗任何部件,除非其(至少)按照第5、6和7节进行了清洁。

D. Parts may be flushed individually by holding them with forceps (or other appropriate means) or placing them in a basket and inserting basket into the catch basin. This normally depends on the size and/or the complexity of the parts.

零件可单独冲洗,方法是用镊子(或其他适当方式)夹持零件或将零件放入篮子,然后将篮子放入收集槽中。这通常取决于零件的尺寸和/或复杂程度。

E. Special particle-free cleanroom gloves shall be worn when flushing and handling test items and while performing testing. Verify that cavities, blind holes, threaded holes, etc., are thoroughly flushed.

冲洗和处理试验物品以及进行试验时,应佩戴无特殊颗粒的洁净室手套,确认彻底冲洗空腔、盲孔、螺纹孔等。

F. Continue until all surfaces have been flushed and a minimum of 100 ml of test fluid has been accumulated.

继续冲洗,直到所有表面都被冲洗干净,并且至少累积了100 ml的测试液体。

G. Transfer the isopropyl alcohol into a clean, dry graduated beaker. Rinse beaker with a small amount of clean fluid, and pour into/include with sample.

将异丙醇转移至洁净干燥的量筒中,用少量洁净液体冲洗量筒,然后倒入/加入样品。

H. Evaporate to 10–20 ml using a rotary evaporation system, steam bath, or equivalent.

使用旋转蒸发系统、蒸汽浴或等效装置蒸馏至10-20 mL。

I. Continue monitoring evaporation until approximately 5 ml. remains in the beaker. Do not allow the isopropyl alcohol to completely evaporate.

继续监测蒸发,直到烧杯中剩余约5 ml。不要让异丙醇完全蒸发。

J. Transfer to a constant weight (± 0.1 mg tare weighing container). Rinse beaker with a small amount of clean fluid, and pour into/include with sample.

转移至恒重(± 0.1 mg)称量容器中,用少量洁净液体冲洗烧杯,然后倒入/加入样品。

K. Place the container in a constant temperature oven at 140 – 160°F (60 – 71°C) until the remainder of the solvent has evaporated.

将容器置于恒温烘箱中,温度为140-160°F(60-71°C),直至剩余溶剂蒸发。

L. Cool in dessicator for a minimum of 15 minutes and then weigh to nearest 0.1 mg.

置于干燥器中冷却至少15分钟,然后称重,精确到0.1 mg。

M. Repeat steps K and L to constant weight.

将步骤K和L重复至恒定重量。

N. Subtract weight of container in step F from weight of container and residue in step H.

在步骤F中,从步骤H中的容器重量和残留物重量中减去容器重量。

O. Compare the results obtained from the used isopropyl alcohol with the results obtained from the same volume of the isopropyl alcohol blank sample. The weight difference shall not be greater than 1.0 mg per square foot of surface area.

将使用后的异丙醇所得结果与相同体积的异丙醇空白样品所得结果进行比较,重量差异应不大于每平方英尺表面积1.0 mg。

P. Record results (see Example Form B)

记录结果(参见示例表格B)

Q. Package/protect items in accordance with Section 11.

根据第11节对物品进行包装/保护。

![图片[8]-SPM 20-90-01波音氧气系统部件清洁工艺(Cobham)-航修札记](https://www.aeroacm.com/wp-content/uploads/2025/08/word-image-8646-8.png)

9. Blank Sample Test 空白样品试验

A. Clean all glassware in accordance with the following:

按照以下要求清洁所有玻璃器皿:

(1) Pre wash – Hand wash using Turco® T-4215 (Metex™ TS-40A optional) detergent and barber shaving-brush, or use automatic dishwasher. At the completion of dishwasher cycle, proceed to step 5.

预洗-使用Turco®T-4215(可选Metex™TS-40A)洗涤剂和剃须刷进行手洗,或使用自动洗碗机。在洗碗机循环完成后,继续执行步骤5。

(2) Place in Turco® T-4215 (Metex™ TS-40A optional) detergent sonics for two minutes.

在Turco®T-4215(可选Metex™TS-40A)清洗剂中超声处理2分钟。

(3) Rinse with hot tap water.

用热水冲洗。

(4) Rinse with deionized water.

用去离子水冲洗。

(5) Rinse with isopropyl alcohol from a filtered IPA dispenser.

用过滤的IPA分配器中的异丙醇冲洗。

(6) Dry part with dry, filtered nitrogen.

用干燥、过滤的氮气吹干部件。

(7) Rinse funnel with super clean isopropyl alcohol from the filtered IPA dispenser.

用超洁净的异丙醇冲洗过滤IPA分配器上的漏斗。

(8) Dry with filtered, dry nitrogen.

用过滤的干燥氮气吹干。

B. Assemble the base of the filtering apparatus in the Laminar Flow Alcohol Flushing Station.

在层流酒精冲洗站中组装过滤装置的底座。

C. Pre rinse a BDWE 04700 (2-Propanol Filter) type filter with isopropyl alcohol (IPA) from the filtered IPA dispenser (2-propanol, BSWP 02500 Millipore). A preliminary visual scan of the filter for contamination is optional.

用异丙醇(IPA)对BDWE 04700(2-丙醇过滤器)型过滤器进行预冲洗,该过滤器来自经过过滤的IPA分配器(2-丙醇,BSWP 02500 Millipore)。可选择对过滤器进行初步污染目视检查。

D. Install the filter in the sampling apparatus between the fritted glass base and the funnel. Clamp both parts together.

将过滤器安装在采样装置的玻璃基座和漏斗之间,夹紧两部分。

E. Flow 100 ml of isopropyl alcohol into the funnel, making sure to wash down the sides of the funnel. When a nonvolatile residue test is required, a 100 ml sample is the minimum.

向漏斗中注入100 ml异丙醇,确保将异丙醇冲洗至漏斗内壁。当需要进行非挥发性残留物检测时,100 ml样本为最小要求。

F. Apply vacuum to draw the isopropyl alcohol through the filter.

施加真空,使异丙醇通过过滤器。

G. Turn off the vacuum and simultaneously remove the holding clamp and filter funnel so that the filter disc remains on the fritted glass base.

关闭真空,同时移除夹持钳和过滤漏斗,使过滤盘保持在玻璃基座上。

H. Remove the filter from the base and transfer to a clean petri slide. The filter should be counted immediately since no further work may take place until the cleanliness of the test fluid is verified.

从基座上取下过滤器并转移至洁净的培养皿载玻片上。应立即对过滤器进行计数,因为在验证试验液的洁净度之前不得进行进一步工作。

I. Perform a particle count following the procedure outlined in Section 10.

按照第10节所述程序进行微粒计数。

J. The blank particulate analysis shall be in accordance with the table below.

空白微粒分析应符合下表。

![图片[9]-SPM 20-90-01波音氧气系统部件清洁工艺(Cobham)-航修札记](https://www.aeroacm.com/wp-content/uploads/2025/08/word-image-8646-9.png)

K. Should test results indicate an out of specification condition (failure), reclean/repeat this process until acceptable levels are obtained.

如果测试结果表明存在超出质量标准的情况(失效),则重新清洁/重复该过程,直至达到可接受水平。

L. Transfer 500 ml of the isopropyl alcohol into a clean, dry 800 ml graduated beaker.

将500 ml异丙醇转移至洁净、干燥的800 ml刻度烧杯中。

M. Evaporate to 10–20 ml using an evaporation system, steam bath or equivalent.

使用蒸发系统、蒸汽浴或同等设备将溶液蒸发至10-20 mL。

N. Continue monitoring evaporation until approximately 5 ml remains in the beaker. Do not allow the isopropyl alcohol to completely evaporate.

继续监测蒸发,直到烧杯中剩余约5 ml。不要让异丙醇完全蒸发。

O. Transfer to a constant/known and recorded, weight (± 0.1 mg tare) container. Rinse the container using a small quantity of fresh solvent, and include in the test Quantity.

转移至恒定/已知并记录的容器(± 0.1毫克净重)。用少量新鲜溶剂冲洗容器,并将其纳入测试量中。

P. Place the container in a constant temperature oven at 120–130°F (49-54°C) until the remainder of the solvent has evaporated.

将容器置于恒温烘箱中,温度为120-130°F (49-54°C),直至剩余溶剂蒸发。

Q. Cool in dessicator for 15 minutes minimum and then weigh to nearest 0.1 mg.

置于干燥器中冷却至少15分钟,然后称重,精确到0.1 mg。

R. Repeat steps P and Q to obtain a consistent weight.

重复步骤P和Q以获得一致的权重。

S. Subtract weight of container in step O from weight of container and residue in step R.

在步骤O中,从容器重量和步骤R中的残留物重量中减去容器重量。

NOTE: Blank sample residue (determined in step S) shall never exceed 1.0 mg/100 ml.

注:空白样品残留(步骤S中测定)不得超过1.0 mg/100 ml。

T. Record results (see Example Form B).

记录结果(参见示例表格B)。

P. Place the container in a constant temperature oven at 120–130°F (49-54°C) until the remainder of the solvent has evaporated.

将容器置于恒温烘箱中,温度为120-130°F (49-54°C),直至剩余溶剂蒸发。

Q. Cool in dessicator for 15 minutes minimum and then weigh to nearest 0.1 mg.

置于干燥器中冷却至少15分钟,然后称重,精确到0.1 mg。

R. Repeat steps P and Q to obtain a consistent weight.

重复步骤P和Q以获得一致的权重。

S. Subtract weight of container in step O from weight of container and residue in step R.

在步骤O中,从容器重量和步骤R中的残留物重量中减去容器重量。

NOTE: Blank sample residue (determined in step S) shall never exceed 1.0 mg/100 ml.

注:空白样品残留(步骤S中测定)不得超过1.0 mg/100 ml。

T. Record results (see Example Form B).

T.记录结果(参见示例表格B)。

10. Particulate Sampling of Cleaned Detail Parts 清洗后的零件的微粒采样

A. All parts to be sampled shall be cleaned in accordance with Sections 5, 6, and 7.

所有待取样的零件应按照第5、6和7节进行清洁。

B. Parts may be grouped according to assemblies or components in order to maintain accurate records.

零件可根据装配或组件进行分组,以便保持准确的记录。

(1) Prior to sampling, all parts must be pre flushed using clean isopropyl alcohol from a filtered dispenser. Clean sampling apparatus in accordance with Section 9.

采样前,必须使用过滤分配器中的洁净异丙醇对所有部件进行预冲洗。采样器具应符合第9节的要求。

(2) Rinse the parts with particle-free solvent and collect into the filter funnel. Particular attention should be paid to internal areas. If the size or shape of the item does not lend itself to flushing directly into the funnel, collect the solvent in a clean glass container of appropriate size, and then pour the solvent onto the funnel. Rinse container using clean solvent and pour into the funnel.

用无颗粒溶剂冲洗零件后,收集到滤液漏斗中。特别要注意内部区域的清洁。若物品尺寸或形状不适合直接冲入漏斗,可先将溶剂收集到适当容量的洁净玻璃容器中,再倒入漏斗。用洁净溶剂冲洗容器后,将其倒入漏斗。

(3) Use a minimum of 500 ml of the solvent for each square foot of significant surface area, unless otherwise specified. If the area is less than a square foot, it shall be the discretion of the operator to determine sample size. A minimum of 100 ml sample shall be taken.

除非另有规定,否则每平方英尺的重要表面积至少使用500 ml溶剂。如果面积小于一平方英尺,则应由操作人员自行决定样本量。至少应取100 ml样本。

(4) Care must be taken in handling the parts during the sampling to avoid the introduction of contamination from other sources.

在取样过程中,必须小心处理零件,以避免来自其他来源的污染。

(5) Turn on vacuum to filter the solvent. When filtration is 2/3 complete, release the vacuum while some liquid remains in the funnel. Carefully wash down the sides of the funnel with clean filtered solvent Reapply vacuum until funnel is empty. Do not rinse the funnel walls after the filter has dried. This will disturb the distribution of particles or fibers on the filter surface.

开启真空以过滤溶剂。当过滤完成三分之二时,释放真空但需保留漏斗内残留液体。用洁净的过滤溶剂仔细冲洗漏斗内壁。重新启动真空直至漏斗完全排空。切记:滤膜干燥后切勿冲洗漏斗内壁,以免破坏滤膜表面颗粒或纤维的分布状态。

(6) Turn off the vacuum and remove the clamp and filter funnel. The filter disc shall remain on the fritted glass base.

关闭真空,取下夹钳和过滤漏斗。过滤盘应留在玻璃基座上。

(7) Remove the filter from the base and transfer it to a clean petri slide.

从基座上取下过滤器,并将其转移至洁净的培养皿载玻片上。

(8) Perform a particle count in accordance with step C, Particle Count Methods.

根据步骤C,粒子计数方法进行粒子计数。

(9) When requirements dictate Total Filterable Solid Weight Test (step D), a blank test filter shall be retained for a comparative test after sampling.

当要求进行总过滤物重量检测(步骤D)时,应在采样后保留空白检测滤器用于比较检测。

C. Particle Count Methods

微粒计数法

All particle counting shall be performed in the Cleanliness Verification Area. The Counting of Particulate shall be performed using the following procedure.

所有微粒计数均应在洁净度验证区域内进行。微粒计数应使用以下程序进行。

(1) Place the petri slide with filter to be read on the microscope stage.

将带滤膜的培养皿载玻片放置在显微镜载物台上进行观察。

(2) Using oblique illumination, adjust the light intensity to obtain maximum particle definition.

使用斜射照明,调节光强度以获得最大的颗粒清晰度。

(3) A magnification of 35X shall be used for counting particles 30 microns or larger, and 100X for counting particles smaller than 30 microns.

使用35倍放大镜对30微米或更大的颗粒进行计数,使用100倍放大镜对小于30微米的颗粒进行计数。

(4) Particles and fibers shall be counted and tabulated according to the largest sizes first. If a particular fiber is found that exceeds the maximum size limitations, the count shall cease and the parts under test shall be re flushed, unless applicable specification (Customer) provides other direction.

应首先根据最大尺寸对颗粒和纤维进行计数并制表。如果发现某个特定纤维超过最大尺寸限制,则停止计数,并重新冲洗受试零件,除非适用规范(客户)提供了其他指示。

(5) Particles smaller than 5 microns are not to be counted by this method.

小于5微米的颗粒物不能用这种方法来计算。

(6) Fibers are defined as any particle whose length-to-diameter ratio exceeds 10 to 1, regardless of composition. Fibers are counted as particles and are not differentiated unless the length exceeds 80 microns. Particle size shall be determined/measured by the greatest dimension. Fibers larger than 80 microns shall be considered only when they appear in the background count of the test filter. If excess fibers are evident, it indicates possible contamination from other sources. Applicable recleaning and re-sampling of the parts shall be performed.

纤维的定义是任何长径比超过10:1的颗粒,无论其成分如何。纤维按颗粒计数,除非长度超过80微米则不作区分。颗粒尺寸应以最大尺寸为准进行测定/测量。当纤维在测试过滤器背景计数中出现时,其长度需超过80微米才视为有效。若发现纤维数量异常增多,可能表明存在其他污染源。此时应立即对相关部件进行重新清洁和采样检测。

(7) At 35X, the ocular scale is calibrated to read 30 microns per division. At 100X, the ocular scale is calibrated to read 10 microns per division. These values have been pre calculated and no further calibration is Necessary.

在35倍放大镜下,目镜刻度校准为每分划读数30微米。在100倍放大镜下,目镜刻度校准为每分划读数10微米。这些数值已预先计算,无需进一步校准。

(8) When using 35X magnification, the entire surface of the filter is scanned and counted under normal conditions. Equipment is to be clean for oxygen service – no visible (viewed without magnification) hydrocarbons, corrosion products, metal chips, weld slag or other contamination.

使用35倍放大镜时,在正常条件下扫描并计数过滤器的整个表面。设备应清洁,以供氧服务使用——在无放大镜观察的情况下,不得看到碳氢化合物、腐蚀产物、金属碎屑、焊渣或其他污染物。

(9) When using 100X magnification, a representative number of grid squares are counted (normally 20 total squares on a double diameter cross pattern). The filter area contains 100 grid squares. Therefore, the results obtained by counting 20 squares are multiplied by a conversion factor of five to arrive at a total statistical count for the entire area of the filter.

在使用100倍放大镜时,需统计具有代表性的网格方格数量(通常采用双直径交叉图案的20个方格)。滤光片区域包含100个网格方格。因此,通过统计20个方格获得的结果需乘以五倍转换系数,即可得出整个滤光片区域的统计总数。

(10) When performing count process, use the counters provided, and record the final tally (see Example Form C).

执行计数过程时,使用提供的计数器,并记录最终计数(参见示例表格C)。

(11) A correction for the minimum volume may be required. Record results (see Example Form C).

可能需要对最小体积进行校正。记录结果(见示例表格C)。

D. Total Filterable Solid Weight Test (performed only when required by contract)

总可过滤固体重量试验(仅在合同要求时进行)

NOTE: This weight analysis is performed in conjunction with the particle sampling test. This test shall be conducted when required by contract.

注:该重量分析与颗粒取样试验一起进行,当合同要求时进行。

(1) The membrane filter, before and after filtration, shall be dried to a constant weight.

过滤前后的膜滤器应干燥至恒重。

(2) Subtract the weight of the filter prior to test, from the weight after test.

从测试后的重量中减去测试前过滤器的重量。

(3) The difference obtained shall not exceed the value stated in the customer specifications.

所得的差值不得超过客户规范中规定的数值。

![图片[10]-SPM 20-90-01波音氧气系统部件清洁工艺(Cobham)-航修札记](https://www.aeroacm.com/wp-content/uploads/2025/08/word-image-8646-10.png)

11. Packaging for Oxygen Cleanliness 氧气包装清洁度

Immediately after a cleaning or disassembly operation, all ports or openings to the functional interior of the oxygen system component shall be capped or plugged using non-shredding dust caps or dust plugs. Caps or plugs must be dry, non-contaminating, and clean to the level of cleanliness specified in Section 1 above. For non-threaded openings and non-standard orifices, cover the opening with a polyethylene bag and secure the bag around the opening or the entire component. For protection when transporting components between cleaning facilities and controlled cleanliness assembly stations, packaging or closing with new, dry, non-contaminating polyethylene film or a bag is acceptable. Do not reuse the film or bags. Components going into storage shall have openings plugged or capped and will be placed in heat-sealed polyethylene bags of a minimum 4 mils thickness if the component weighs less than 1 pound; use 6 mil minimum thickness polyethylene to package all others.

在完成清洁或拆卸作业后,应立即使用防碎防尘盖或防尘塞封住氧气系统组件功能内部的所有端口或开口。封盖或塞子必须保持干燥、无污染,并达到上文第1节规定的洁净度标准。对于非螺纹开口及非标准孔口,可用聚乙烯袋覆盖开口并将其固定于开口处或整个组件。在运输组件于清洁设施与受控洁净组装站之间时,可采用全新干燥且无污染的聚乙烯薄膜或袋子进行包装密封。严禁重复使用已用过的薄膜或袋子。待入库组件需封堵或加盖开口,重量不足1磅的组件应装入至少4密耳厚度的热封聚乙烯袋;其他所有组件则需使用6密耳最小厚度的聚乙烯材料进行封装。

APPENDIX A附录a

Cleaning Process for Transducers 传感器的清洁过程

A1. Scope

A1.范围

Since transducers may be damaged when submerged in cleaning solution as described in Section 6, this appendix defines cleaning procedures that are specific to transducers. However, the classification, cleanliness, packaging, marking, and inspection requirements defined elsewhere in the main body of this document still apply. Cleaning of transducers requires the use flushing fixtures. This appendix applies to the following transducers and associated fixtures and fittings:

由于传感器在浸入清洁溶液时可能受损(如第6节所述),本附录制定了专门针对传感器的清洗规程。但需注意,本文正文中其他章节规定的分类、洁净度、包装、标识及检验要求仍适用。传感器清洗必须使用冲洗装置。本附录适用于以下传感器及其配套的冲洗装置和连接件:

![图片[11]-SPM 20-90-01波音氧气系统部件清洁工艺(Cobham)-航修札记](https://www.aeroacm.com/wp-content/uploads/2025/08/word-image-8646-11.png)

A2. Cleaning Procedure

A2. 清洁程序

A. Verify that the unit has been disassembled IAW the applicable CMM.

验证部件是否已拆卸至适用的CMM。

CAUTION: DO NOT TOUCH TRANSDUCER SENSING MEMBRANE WITH ANY HARD OBJECT AS IT MAY DAMAGE MEMBRANE.

注意:请勿用任何硬物接触探头感应膜,否则可能损坏感应膜。

B. Verify that the Flushing Fixture has been cleaned IAW Section 9, Cleaned for Oxygen service. Install the Flushing Fixture IAW Figure 1.

根据IAW第9节“ Cleaned for Oxygen service”验证冲洗夹具是否已清洁。安装冲洗夹具IAW图1。

![图片[12]-SPM 20-90-01波音氧气系统部件清洁工艺(Cobham)-航修札记](https://www.aeroacm.com/wp-content/uploads/2025/08/word-image-8646-12.png)

C. The cleaning and testing shall be performed using isopropyl alcohol, which has been sampled in accordance with Section 9.

应使用异丙醇进行清洁和试验,根据第9节对异丙醇进行了取样。

D. Fill the Gelman™ with the tested isopropyl alcohol (TT-I-735, Grade A or B) and attach to the Flushing Fixture. Flush/clean the item with a minimum of 20 milliliters of alcohol (do not collect as sample).

用已测试的异丙醇(TT-I-735,A级或B级)灌注Gelman™,然后将其连接到冲洗夹具上。使用至少20毫升酒精冲洗/清洁物品(不要收集作为样品)。

E. Flush and collect an additional 5 milliliters minimum. Add this sample to the samples collected from the other parts of the unit (total fluid sample shall be a minimum of 100 milliliters).

冲洗并收集至少额外的5毫升液体。将该样本与从部件其他部位收集的样本一起加入(总液体样本应至少为100毫升)。

F. Dry items using filtered, dry nitrogen, at a maximum regulated pressure of 40 psig. Vacuum bake at 120°F (49°C) for 1 hour min. at ≤ .25 psia (.02 bara) to ensure total removal of all test fluid.

用过滤的干燥氮气对干燥物品进行干燥,最大调节压力为40 psig。在≤.25 psia(0.02 bar)下真空烘烤1小时,温度为120°F(49°C),以确保完全去除所有测试液体。

G. Perform the Non Volatile Residue measurement and record data in accordance with Section 8 of this procedure.

根据本规程第8节进行非挥发性残留物测量并记录数据。

APPENDIX B附录B

Use of Isopropyl Alcohol in Cleaning Processes. 在清洁过程中使用异丙醇。

In response to the requirements of the Montreal Protocol on Ozone Depleting Substances, a cleaning system with an aqueous alkaline medium and a de-ionized water rinse is now used.

为响应《关于消耗臭氧层物质的蒙特利尔议定书》的要求,现在使用一种采用碱性水介质和去离子水冲洗的清洗系统。

Isopropyl Alcohol (IPA) is used for two purposes in the cleaning process:

在清洁过程中,异丙醇(IPA)用于两个目的:

1. As a drying aid, to ensure that all water is removed from the internal passageways of complex parts after cleaning.

作为干燥辅助工具,确保清洗后从复杂部件的内部通道中去除所有水分。

2. As a test medium where Non Volatile Residue testing is required.

作为需要进行非挥发性残留物检测的试验介质。

There have been some objections raised about the use of Isopropyl Alcohol for oxygen cleaning. A NASA report indicated that IPA leaves a significant residue when used for cleaning/flushing of parts. However, this is contrary to much field experience using IPA and the findings of this report have been questioned. The test described in the NASA report consisted of:

关于使用异丙醇进行氧气清洗的争议持续发酵。美国国家航空航天局(NASA)报告显示,该溶剂在清洗或冲洗零件时会产生明显残留物。但这一结论与大量现场实践经验相悖,相关研究结果也遭到质疑。NASA报告中描述的测试包含以下内容:

a) Immersing identical samples simultaneously in Freon and Isopropyl Alcohol.

将相同的样品同时浸入氟利昂和异丙醇中。

b) Removing both samples from the solvents simultaneously, and weighing both of them at the exact moment the Freon was observed to have evaporated from its sample.

同时从溶剂中取出两个样品,并在观察到氟利昂从样品中蒸发的准确时刻对二者进行称量。

c) The difference between the starting weight and the post dip weight was recorded as the weight of residue.

记录起始重量和后浸提重量之间的差值作为残留物重量。

This test simply proves that alcohol takes longer to evaporate than Freon. This issue has been discussed with personnel from the United States Air Force at Tinker Air Force Base, who are pursuing their own tests of residue formation. Other testing has been performed that indicates that, when the IPA has evaporated, there is no more residue present than there is with Freon.

这项测试结果表明,酒精的挥发速度确实比氟利昂要慢。我们已就此问题与美国空军廷克空军基地的人员进行过沟通,他们正在开展自己的残留物形成实验。其他测试数据也显示,当异丙醇完全挥发后,其残留量与氟利昂相比并无差异。

Other objections have been raised to the use of IPA as a result of accidents which have happened when this medium has been used to clean full up assemblies in the field. In those incidents, the problem can be directly attributed to the failure to remove the alcohol completely from the units before returning them to service. This resulted from flushing at low temperatures when the alcohol gelled and did not evaporate, or to a failure to use an adequate post-flush purging process.

由于在野外作业中使用IPA清洗组件时发生事故,引发了对IPA使用的其他质疑。这些事故直接归因于设备重新投入使用前未能彻底清除残留酒精。究其原因,要么是低温冲洗导致酒精凝胶化无法挥发,要么是后续未进行充分的冲洗后吹扫处理。

Completed assemblies must not be flushed with IPA and those items which are cleaned with IPA must be subjected to baking, hot air drying or nitrogen gas purging to ensure that all alcohol is removed from the component.

不得用IPA冲洗已完成组装的部件,必须对使用IPA清洁的物品进行烘烤、热空气干燥或氮气吹扫,以确保从组件中去除所有酒精。

As a result of these considerations, it is believed that the processes described in this document, which include the use of IPA as a flushing/cleaning medium, are entirely safe and consistent with the end use of the equipment.

基于这些考虑,认为本文件中描述的工艺(包括使用IPA作为冲洗/清洁介质)是完全安全的,并且与设备的最终用途一致。

![图片[13]-SPM 20-90-01波音氧气系统部件清洁工艺(Cobham)-航修札记](https://www.aeroacm.com/wp-content/uploads/2025/08/image-50-1024x390.png)

暂无评论内容