CAUTION: DO NOT USE THE MECHANICAL STANDARD PRACTICES MANUAL BY ITSELF. USE IT ONLY AS SPECIFIED IN THE APPLICABLE COMPONENT MAINTENANCE MANUAL OR OTHER FAA-APPROVED DOCUMENTS. 警告:严禁单独使用《机械标准操作手册》。仅可依据适用部件维护手册或其他联邦航空局批准文件中的规定使用。

基本数据

• Use this to mark data on parts. The marks must be durable and stay legible for the normal life expectancy of a part or an assembly.

• 用于标注零件数据。标记必须持久耐用,在零件或组件正常使用寿命期间保持可读性。

• The necessary mark data is only applicable to a completed part or assembly.

• 必要标记数据仅适用于完成的零件或组件。

• Do not make a permanent mark on the dash numbered details of a part or an assembly unless specific instructions are given.

• 除非另有明确指示,不得在零件或组件的带破折号编号信息上进行永久性标记。

• Unless given specific instructions, all mark characters must be between 0.060 to 0.090 inch (1.524 to 2.286 mm) in height.

• 除非另有明确指示,所有标记字符高度必须在0.060至0.090英寸(1.524至2.286毫米)之间。

• Make sure that you can read all of the marks after the plate or coat processes have been completed.

• 确保在完成镀层或涂层工艺后,所有标记均可清晰辨识。

• Refer to Chapter 11, COATINGS, for procedures to replace a protective coat that has been removed.

• 有关修复受损保护涂层的操作程序,请参阅第11章《涂层工艺》。

• If a part or an assembly has been changed, mark the part or the assembly again.

• 若零件或组件发生变更,须重新进行标记。

• Unless given specific instructions, the new marks must be adjacent to the marking used before.

• 除非另有说明,新标记必须紧邻原有标记位置。

标记制作程序

A. Task 1: Deep Impression Mark

任务1:深压印标记

(1) Procedure 1: Hand Stamp

程序1:手工冲压

WARNING: USE GOGGLES WHEN YOU MARK THE PARTS. PIECES OF THE PART CAN GET IN YOUR EYES.

警告:标记零件时必须佩戴护目镜。零件碎屑可能飞溅入眼。

(a) Use a hand hammer and a punch stamp to make the characters. This will displace material.

使用手锤与冲头制作字符,此法会产生材料位移。

(b) Do not use this method if the hardness of the part is higher than Rockwell C45.

若零件硬度高于洛氏硬度C45,禁止使用此方法。

(c) The area to be stamped must be well supported.

被标记区域必须充分支撑。

(d) The maximum character depth is 0.010 inch (0.254 mm).

字符最大深度为0.010英寸(0.254毫米)。

(2) Procedure 2: Engrave

程序二:刻印

WARNING: USE GOGGLES WHEN YOU MARK THE PARTS. PIECES OF THE PART CAN GET IN YOUR EYES.

警告:标记零件时必须佩戴护目镜。零件碎屑可能飞溅入眼。

(a) Use a rotating cutter or grinder to make the characters.

使用旋转切割机或砂轮机刻制字符。

(b) The character depth will be between 0.003 to 0.010 inch (0.076 to 0.254 mm).

字符深度应在0.003至0.010英寸(0.076至0.254毫米)之间。

B. Task 2: Shallow Impression Mark

任务2:浅压印标记

(1) Procedure 1: Vibration Peen

程序1:振动压印

WARNING: USE GOGGLES WHEN YOU MARK THE PARTS. PIECES OF THE PART CAN GET IN YOUR EYES.

警告:标记零件时必须佩戴护目镜。零件碎屑可能飞溅入眼。

(a) Use a radius-tipped, conical tool that vibrates to make the characters.

使用振动式圆锥形圆角工具进行刻字。

(b) Do not use this method if the hardness of the part is higher than Rockwell C45.

若零件硬度高于洛氏硬度C45,禁止采用此方法。

(c) Aluminum or aluminum alloys can be marked by this method after anodizing.

铝或铝合金经阳极氧化处理后可采用此法标记。

(d) If the characters are made after the part has been anodized, refer to Chapter 11, COATINGS, to touch up with conversion coating, such as Alodine, the changed area.

若字符在零件阳极氧化后制作,需参照第11章《涂层》使用转化涂层(如Alodine)修补受影响区域。

(e) The maximum character depth is 0.006 inch (0.152 mm).

字符最大深度为0.006英寸(0.152毫米)。

C. Task 3: Electrolytic Etch

任务3:电蚀刻

(1) General

概述

• Use a small amount of electric current and an applicable electrolyte to make the characters.

采用微弱电流与适用电解液形成字符。

• Apply the electric current through a stencil with a hand-held marking tool and a grounding clip attached to the part being marked. Follow the manufacterer’s instructions.

使用手持标记工具通过模板施加电流,并连接接地夹至待标记零件。遵循制造商说明。【stencil:用模板印刷】

• The type of electrical current and the type of electrolyte must agree with the characteristics of the material to be marked.

电流类型与电解液类型须符合待标记材料特性。

• The maximum impression depth is not larger than 0.003 inches (0.076 mm).

最大压痕深度不得超过0.003英寸(0.076毫米)。

• Parts must be thoroughly rinsed to remove all traces of the electolytic etch fluid.

零件必须彻底冲洗以清除所有电蚀刻液残留。

(2) Procedure 1: Non-Aluminum

程序1:非铝材质

WARNING: USE GOGGLES WHEN YOU MARK THE PARTS. CHEMICALS CAN GET IN YOUR EYES.

警告:标记零件时必须佩戴护目镜。化学物质可能溅入眼睛。

(a) The parts to be marked must be clean.

被标记的零件必须清洁。

(b) Make the stencil and apply to the part to be etched.

制作模板并覆盖于待蚀刻的零件。

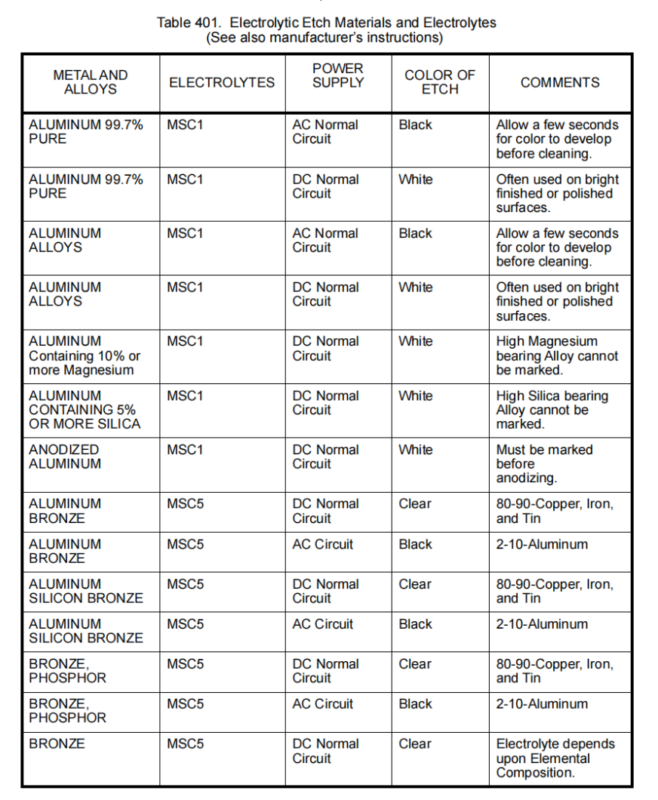

(c) Use the applicable electrolyte and current from Table 401.

选用表401对应的电解液及电流参数。

(d) Apply the electrolyte to the etch pad.

将电解液涂布于蚀刻垫。

(e) To mark the part, use sufficient pressure to make sure the etch pad, the stencil and the part are in contact.

标记时施加足够压力确保蚀刻垫、模板与零件紧密接触。

(f) Time of contact with the part is 4 or 5 seconds.

与零件接触时间为4至5秒。

(g) Wipe off any liquid electrolyte.

擦拭残留电解液。

(h) Wipe part with a solution that neutralizes and make sure the part is dry.

用中和溶液擦拭零件并确保完全干燥。

(i) If the characters are not clear:

若字符不清晰:

NOTE: Bear-Tex is a coarse abrasive material that is used to remove a large quantity of material. Scotch-Brite is a fine abrasive material that is used to remove a smaller quantity of material than will be removed with the Bear-Tex.

注:Bear-Tex是一种粗磨料,用于去除大量材料。Scotch-Brite为细磨料,用于去除比Bear-Tex更少量的材料。

1 Rub the area that was marked with a light emery cloth or suitable abrasive product such as “Bear-Tex”, “Cratex” or “Scotch-Brite” to remove the characters.

用细砂纸或“Bear-Tex”、‘Cratex’、“Scotch-Brite”等适宜磨料擦拭标记区域以去除字符。

2 Apply the stencil to the part to be etched.

将模板覆盖于待蚀刻零件。

3 Use the applicable electrolyte and current from Table 401. See also HS 333, and the manufacturer’s instructions for the electolyte.

参照表401选用适用的电解液与电流参数。另请查阅HS 333及电解液制造商说明。

4 To mark the part, use sufficient pressure to make sure the etch pad, the stencil and the part are in contact.

标记时施加足够压力,确保蚀刻垫、模板与零件紧密接触。

5 Time of contact with the part is usually 4 or 5 seconds.

接触零件时间通常为4至5秒。

6 Wipe off any liquid electrolyte.

擦拭残留电解液。

7 Wipe part with a neutralizing solution and make sure the part is dry.

用中和溶液擦拭零件并确保其干燥。

(3) Procedure 2: Aluminum or Aluminum Alloy

程序二:铝或铝合金

WARNING: USE GOGGLES WHEN YOU MARK THE PARTS. CHEMICALS CAN GET IN YOUR EYES.

警告:标记零件时必须佩戴护目镜。化学物质可能溅入眼睛。

(a) Do not etch on any anodized surface.

不得在阳极氧化表面进行蚀刻。

(b) If the part must be etched, remove the anodize surface.

若必须蚀刻,需先去除阳极氧化层。

(c) The parts to be marked must be clean.

需标记的零件必须清洁。

(d) Make the stencil and apply to the part to be etched.

制作模板并覆盖于待蚀刻零件。

(e) Use the applicable electrolyte and current from Table 401.

选用表401对应的电解液及电流参数。

(f) Apply the electrolyte to the etch pad.

将电解液涂布于蚀刻垫。

(g) To mark the part, use sufficient pressure to make sure the etch pad, the stencil and the part are in contact.

标记时施加足够压力确保蚀刻垫、模板与零件紧密接触。

(h) Time of contact with the part is 4 or 5 seconds.

与零件接触时间为4至5秒。

(i) Wipe off any liquid electrolyte.

擦拭残留电解液。

(j) Wipe part with a solution that neutralizes and make sure the part is dry.

用中和溶液擦拭零件并确保完全干燥。

(k) If the characters are made after the part has been anodized, refer to Chapter 11, COATINGS, to touch up the changed area.

![图片[1]-MARKING 标识-航修札记](https://www.aeroacm.com/wp-content/uploads/2026/01/20260127230043719-image-842x1024.png)

![图片[2]-MARKING 标识-航修札记](https://www.aeroacm.com/wp-content/uploads/2026/01/20260127230051342-image-842x1024.png)

![图片[3]-MARKING 标识-航修札记](https://www.aeroacm.com/wp-content/uploads/2026/01/20260127230058692-image-831x1024.png)

![图片[4]-MARKING 标识-航修札记](https://www.aeroacm.com/wp-content/uploads/2026/01/20260127230104964-image.png)

![图片[5]-MARKING 标识-航修札记](https://www.aeroacm.com/wp-content/uploads/2026/01/20260127230112104-image-854x1024.png)

![图片[6]-MARKING 标识-航修札记](https://www.aeroacm.com/wp-content/uploads/2026/01/20260127230118163-image.png)

D. Task 4: Ink Mark

任务4:油墨标记

(1) Procedure 1: Ink Mark. Use State Stamp TT-I-558 or AA-208-A, Type 1. For aluminum and plastic parts, use epoxy base ink per A-A-56032 or MIL-I-43553.

程序1:油墨标记。使用州印章TT-I-558或AA-208-A(1型)。铝制及塑料零件需采用符合A-A-56032或MIL-I-43553标准的环氧基油墨。

(a) Use a permanent ink that dries fast to make the characters.

使用快干型永久油墨制作字符。

(b) The parts to be marked must be clean.

被标记零件必须清洁。

(c) Apply ink with a pen, brush, marker and a stencil or rubber stamp.

采用钢笔、刷具、标记笔配合模板或橡胶印章施墨。

(2) Procedure 2: Ink Mark Covered with a Clear Layer

程序2:透明层覆盖油墨标记

(a) Use an India ink that dries fast to make the characters.

使用速干印度墨水绘制字符。

(b) The parts to be marked must be clean.

被标记零件必须清洁。

(c) The characters must be covered with a protective layer of clear epoxy or urethane. Refer to Chapter 11, COATINGS, for the applicable procedure.

字符必须覆盖透明环氧树脂或聚氨酯保护层。具体操作参见第11章《涂层》。

NOTE: Marking can be done by Vibropeening with a carbide tip.

注:可采用碳化物尖头的振动铣削工艺进行标记。

NOTE: Laser marking is acceptable on nonmagnetic stainless steels and on most non-elastomer plastics.

注:在非磁性不锈钢及大多数非弹性体塑料上允许采用激光标记。

E. Task 5: Mark Hamilton Sundstrand Identification Plates

任务5:标记HS识别铭牌

(1) The Hamilton Sundstrand identification plate supplies information about the unit.

HS识别牌提供部件相关信息。

(a) This can include but is not limited to part number, serial number, CAGE code, part name, and model.

信息包括但不限于件号、序号、CAGE代码、零件名称及型号。

(b) Other customer or contract specific information can also be included on the identification plate.

识别标牌亦可包含其他客户或合同特定信息。

(c) Some HS parts are identified with both human-readable and two-dimensional (2D) machine readable information on the identification plate.

部分HS零件的识别标牌同时标注人眼可读信息与二维(2D)机器可读信息。

(2) For plates larger than 0.008 inch (0.20 mm) thick:

针对厚度大于0.008英寸(0.20毫米)的铭牌:

(a) Use the hand stamp marking procedure or shallow vibration peen marking procedure to mark the necessary information on the nameplate.

采用手工冲压标记法或浅振动锤击标记法在铭牌上标注必要信息。

(b) The characters must be filled with a red pigment such as “Markal B Paintstik”.

字符必须填充红色颜料(如“Markal B Paintstik”)。

(c) Rub the pigment across the nameplate.

将颜料涂抹于铭牌表面。

(d) Rub a clean cloth across the nameplate to wipe off any excess pigment.

用干净布料擦拭铭牌表面,清除多余颜料。

(e) To apply the nameplate to the part, refer to Chapter 14, ASSEMBLY AND REPAIRS, or the applicable Component Maintenance Manual, for instructions.

铭牌安装操作请参照第14章《组装与修理》或相应部件维护手册中的说明。

(3) For plates equal to or smaller than 0.008 inch (0.20 mm) thick:

厚度等于或小于0.008英寸(0.20毫米)的铭牌:

(a) Use the hand stamp marking procedure, shallow vibration peen marking procedure or a typewriter with the typewriter ribbon removed to mark the necessary information on the nameplate.

采用手工压印标记法、浅振动锤击标记法或拆去色带的打字机,在铭牌上标注必要信息。

(b) The characters must be filled with a red pigment, such as “Markal B Paint Stick” or “Wipe on Paint in Stick Form” by Lake Chemical Co.

字符必须填充红色颜料,例如莱克化学公司生产的“Markal B Paint Stick”或“棒状擦涂颜料”。

(c) Rub the pigment across the nameplate.

将颜料涂抹于铭牌表面。

(d) Rub a clean cloth across the nameplate to wipe off any excess pigment.

用干净布料擦拭铭牌表面,清除多余颜料。

(e) To apply the nameplate to the part, refer to Chapter 14, Repairs Section, or the applicable Component Maintenance Manual, for instructions.

铭牌安装方法参见第14章修理章节或相应部件维护手册。

(4) As an alternative to stamp or peen marking methods, laser marking is permitted on 300 series steel, and solid color background aluminum identification plates.

除冲压或锤击标记法外,允许在300系列钢材及纯色背景铝制识别板上采用激光标记。

(a) The laser markings can be made by heat tinting or surface melting, but markings must not cause deformation or buckling of the plate.

激光标记可采用热着色或表面熔融工艺,但标记不得导致铭牌变形或翘曲。

(b) For adhesive backed plates, there must be no sign of degradation of the adhesive outer side of the area immediately opposite of the marking, and no bubbling or blistering of the adhesive that can prevent the plate from lying flat and fully touching a flat surface.

对于背胶铭牌,标记区域正对面的胶粘剂外侧不得出现劣化迹象,且胶粘剂表面不得产生气泡或起泡,以免影响铭牌平整贴合于平面。

(c) To apply the nameplate to the part, refer to Chapter 14, ASSEMBLY AND REPAIRS, or the applicable Component Maintenance Manual, for instructions.

铭牌安装操作请参照第14章《组装与修理》或适用部件维护手册中的说明。

F. Task 6: Laser Part Marking (Stress Raiser)

任务6:激光零件标记(应力集中区)

(1) Laser marking is done by melting the surface in a specific pattern to produce the required letters and numbers.

激光标记通过按特定图案熔化表面形成所需字母数字。

(2) The marking may resemble a bead or plate weld, slightly raised above the surface, or trough not exceeding 0.0015 (0.0380 mm) deep that may or may not have raised edges.

标记可呈现为略高于表面的珠状或板焊状,或深度不超过0.0015英寸(0.0380毫米)的凹槽(边缘可有可无凸起)。

(3) When used on martensitic or martensitically hardened steels, the part shall be retempered after marking at the previous tempering temperature minus 50°F (27°C) plus 0°F (0°C) for one hour.

若在马氏体或马氏体淬硬钢上使用,零件在标记后需在原回火温度减去50°F(27°C)加0°F(0°C)的温度下回火1小时.

G. Task 7: Laser Part Marking (Non Stress Raiser)

任务7:激光零件标记(非应力增高)

(1) Laser marking in this manner will cause dark heat treat on the material, but there will be no visible sign of raised ridges or troughs.

此类激光标记将在材料上形成暗色热处理痕迹,但不会产生可见的凸起棱脊或凹槽。

(2) It is applicable to thin materials such as shims and sheet metal parts.

适用于垫片及薄板金属件等薄型材料。

耗材

A. Table 402 will give you the necessary data to do the procedures in this section.

表402提供执行本节程序所需数据。

NOTE: Maintenance personnel must use the specified consumable material for the specified task. These consumable materials are known to agree with all of the design and qualification requirements. Only approved materials engineering personnel can make equivalent consumable material decisions. These materials are used at the risk of the organization who makes the decision.

注意:维护人员必须使用指定任务的专用耗材。这些耗材已通过所有设计与认证要求验证。仅经批准的材料工程人员可决定使用等效耗材,相关决策风险由决策组织自行承担。

NOTE: You can get the full address and other information for vendors or suppliers listed in this table from the World Wide Web (www) at URL http://www.bpn.gov/ bincs/begin_search.asp. Other CAGE Code sites are also available on the Web.

注:本表所列供应商的完整地址及其他信息可通过万维网(www)查询,网址为:http://www.bpn.gov/bincs/begin_search.asp。其他CAGE代码网站亦可通过网络获取。

![图片[7]-MARKING 标识-航修札记](https://www.aeroacm.com/wp-content/uploads/2026/01/20260127230432397-image.png)

二维机器可读零件标识

A. Some HS parts are identified with both human-readable and two-dimensional (2D) machine readable information.

部分HS零件同时采用人眼可读与二维(2D)机器可读信息标识。

(1) HS parts with machine readable part identification will typically have two matrix marks applied to the product. The primary mark contains the CAGE code and serial number, and the secondary mark contains the current part number. See Figure 401.

带机器可读标识的HS零件通常在产品上施加两个矩阵标记。主标记包含CAGE代码和序列号,副标记包含当前零件编号。参见图401。

![图片[8]-MARKING 标识-航修札记](https://www.aeroacm.com/wp-content/uploads/2026/01/20260127230530188-image.png)

(2) The basic 2D data matrix requirements to be used on HS parts are in Table 403.

HS零件所用基础二维数据矩阵要求详见表403。

![图片[9]-MARKING 标识-航修札记](https://www.aeroacm.com/wp-content/uploads/2026/01/20260127230547864-image.png)

(3) If it is necessary to modify the part number of 2D machine readable marking, the 2D matrix data containing the old part number must be completely obliterated. If possible, make a new 2D machine readable marking to accompany the new (human readable) part number. See Figure 402.

若需修改二维机器可读标记的件号,必须彻底清除含旧编号的二维矩阵数据。若条件允许,应制作新的二维机器可读标记配合新版(人眼可读)件号使用。参见图402。

NOTE: If an identification plate or label is used, the best practice is to completely replace the identification plate or label containing only the new part number data.

注:若使用识别铭牌或标签,最佳实践是完全替换仅含新零件号数据的识别铭牌或标签.

![图片[10]-MARKING 标识-航修札记](https://www.aeroacm.com/wp-content/uploads/2026/01/20260127230614944-image.png)

暂无评论内容