磨料清洗程序

A. Deleted.

已删除。

B. Task 1: Dry Abrasive Blast

任务1:干式磨料喷砂

CAUTION: DO NOT USE DRY ABRASIVE BLAST ON SURFACES WITH 63 RA OR FINER FINISH. ALSO, DO NOT USE ON VALVE WORKING SURFACES.

警告:严禁对表面粗糙度63 RA及更精细的表面进行干式磨料喷砂。同时禁止用于活门工作面。

(1) All parts must be free of oil and clean.

所有零件必须彻底除油并清洁。

(2) Apply protective material or plug all areas that will not be dry abrasive blasted.

对非喷砂区域覆盖防护材料或进行封堵。

(3) Put the parts inside the blast cabinet.

将零件置于喷砂柜内。

WARNING: THE VENTILATION SYSTEM MUST BE OPERATING. USE BREATHING PROTECTION AND GLOVES WITH GAUNTLETS WHEN YOU BLAST ABRASIVE PARTICLES. THE PARTICLES CAN DAMAGE YOUR BODY AND EYES, AND THE DUST CAN CAUSE DAMAGE TO YOUR RESPIRATORY TRACT.

警告:通风系统必须持续运行。喷砂作业时必须佩戴呼吸防护装置及带护腕的手套。砂粒可能损伤身体及眼睛,粉尘会危害呼吸道。

(4) Use the specified material and grit size; when not stated, use 240 or finer mesh.

使用指定材料及粒度;未指定时采用240目或更细砂粒。

(5) Set air pressure between 30 and 50 PSIG.

设定气压在30至50磅/平方英寸(PSIG)之间。

(6) Position the blast nozzle as follows:

喷嘴定位要求:

(a) The angle of the nozzle must be set at approximately 30 to 90 degrees to the surface to be blasted.

喷嘴与待喷表面夹角应保持在30至90度。

(b) The distance of the nozzle to the part surface will be between 2.0 to 4.0 inch (4.45 to 9.00 cm).

喷嘴与零件表面距离需控制在2.0至4.0英寸(4.45至9.00厘米)。

(7) Dry abrasive blast the part.

对零件进行干式磨料喷砂处理。

NOTE: Do not permit nozzle to stay in one area for an extended time.

注意:喷嘴不得在同一区域停留过久。

(8) Visually inspect the part surface to make sure the blasted area is evenly coated. Repeat steps (6) and (7) if necessary.

目视检查零件表面,确保喷砂区域均匀覆盖。必要时重复步骤(6)和(7)。

(9) Remove the protective material or plugs from the part.

移除零件上的防护材料或堵头。

(10) Visually inspect the part surface to make sure all of the abrasive has been removed.

目视检查零件表面,确保所有磨料已被清除。

WARNING: WHEN YOU USE COMPRESSED AIR TO CLEAN OR DRY PARTS, MAKE SURE THAT THE PRESSURE IS NOT MORE THAN 30 POUNDS PER SQUARE INCH (207 KILOPASCALS). DO NOT DIRECT THE AIRSTREAM AT PERSONNEL OR LIGHT OBJECTS. PUT ON GOGGLES OR A FACE SHIELD TO PROTECT YOUR EYES. THIS WILL HELP TO PREVENT INJURIES TO PERSONNEL OR DAMAGE TO THE EQUIPMENT. IF YOU HAVE AN EYE INJURY, GET MEDICAL ATTENTION.

警告:使用压缩空气清洁或干燥零件时,确保压力不超过30磅/平方英寸(207千帕)。切勿将气流直接吹向人员或易燃物体。佩戴护目镜或面罩保护眼睛。此举可有效防止人员受伤或设备损坏。若发生眼部损伤,请立即就医。

(11) Use a low pressure air gun with clean, dry oil-free air to remove any grit.

使用低压气枪配合洁净干燥的无油压缩空气清除砂粒。

(12) Refer to Chapter 16, Storage and Preservation, for instructions to apply finger print neutralizer per MIL-C-15074 and/or additional preservation.

参照第16章《储存与保养》中关于按MIL-C-15074标准涂覆指纹中和剂及/或实施附加保养的操作指南。

C. Task 2: Wet Abrasive Blast

任务2:湿式喷砂

CAUTION: DO NOT USE DRY ABRASIVE BLAST ON SURFACES WITH 32 RA OR FINER FINISH. ALSO, DO NOT USE ON VALVE WORKING SURFACES.

警告:严禁对表面粗糙度32 RA及更精细的表面进行干式喷砂处理,亦不得用于活门工作面。

(1) All parts must be free of oil and clean.

所有零件必须彻底除油并清洁。

(2) Apply protective material or plug all areas that will not be wet abrasive blasted.

对非喷砂区域覆盖防护材料或进行封堵。

(3) Use the specified material and grit size. Although various materials and grit sizes are used, 320 mesh and 400 mesh are most often used for overhaul and repair cleaning purposes.

使用指定材料及粒度规格。虽存在多种材料与粒度选择,但320目和400目砂粒最常用于大修及维修清洁。

(4) Check the wet abrasive blast solution once each work shift.

每班次检查一次湿式磨料喷砂溶液。

NOTE: Slurry must be discarded and replaced after 30 hours of use.

注意:使用30小时后必须废弃并更换砂浆。

(a) Shake the slurry for a minimum of 5 minutes.

充分搅拌砂浆至少5分钟。

(b) Immerse a 100cc graduated cylinder into the slurry.

将100毫升量筒浸入砂浆中。

(c) Put the graduated cylinder on a flat surface for one hour. This will let the abrasive to go to the bottom of the cylinder.

将量筒置于平坦表面静置一小时,使磨料沉降至底部。

(d) Examine the quantity of slurry in the graduated cylinder. The abrasive level will be 35 – 45% of the total volume (the 35 – 45 ml level).

观察量筒内砂浆液位。磨料含量应维持在总体积的35-45%(即35-45毫升刻度线)。

(5) Put the part inside the blast cabinet.

将零件放入喷砂柜。

WARNING: USE GLOVES WITH GAUNTLETS WHEN YOU BLAST ABRASIVE PARTICLES. THE PARTICLES CAN DAMAGE YOUR BODY AND EYES, AND THE DUST CAN CAUSE DAMAGE TO YOUR RESPIRATORY TRACT.

警告:喷砂作业时必须佩戴带护腕的手套。磨料颗粒可能损伤身体及眼睛,粉尘会危害呼吸道。

(6) Set air pressure between 70 and 90 PSIG.

将气压设定在70至90磅/平方英寸(PSIG)之间。

(7) Position the blast nozzle as follows:

喷嘴定位要求:

(a) The angle of the nozzle will be set at approximately 90 degrees to the surface to be blasted.

喷嘴与待喷表面保持约90度夹角。

(b) The distance of the nozzle to the part surface will be between 3.0 to 4.0 inch (6.75 to 9.00 cm).

喷嘴与零件表面距离为3.0至4.0英寸(6.75至9.00厘米)。

(8) Wet abrasive blast the part to parameters specified in CMM.

按照CMM规定的参数对零件进行湿式磨料喷砂处理。

NOTE: Do not permit nozzle to stay in one area for an extended time.

注意:禁止喷嘴在同一区域停留过久。

(9) Visually inspect the part surface to make sure the blasted area is constant. Repeat steps (6) and (7) if necessary.

目视检查零件表面,确保喷砂区域均匀一致。必要时重复步骤(6)和 (7) 步骤。

(10) Remove the protective material or the plugs from the part.

移除零件上的防护材料或堵头。

(11) Immerse the part in hot 150°-190F° (66°-88C°) water and agitate the part lightly for 15 minutes minimum until all abrasives have been removed. You may add a corrosion inhibitor to the water.

将零件浸入150°-190°F(66°-88°C)热水中,轻柔搅动至少15分钟直至清除所有磨料。水中可添加腐蚀抑制剂。

WARNING: WHEN YOU USE COMPRESSED AIR TO CLEAN OR DRY PARTS, MAKE SURE THAT THE PRESSURE IS NOT MORE THAN 30 POUNDS PER SQUARE INCH (206.8 KILOPASCALS). DO NOT DIRECT THE AIRSTREAM AT PERSONNEL OR LIGHT OBJECTS. PUT ON GOGGLES OR A FACE SHIELD TO PROTECT YOUR EYES. THIS WILL HELP TO PREVENT INJURIES TO PERSONNEL OR DAMAGE TO THE EQUIPMENT. IF YOU HAVE AN EYE INJURY, GET MEDICAL ATTENTION.

警告:使用压缩空气清洁或干燥零件时,确保压力不超过每平方英寸30磅(206.8千帕)。切勿将气流直接对准人员或易燃物体。佩戴护目镜或面罩保护眼睛。此举可有效预防人员受伤或设备损坏。若发生眼部损伤,请立即就医。

(12) Use a low pressure air gun with clean, dry oil-free air to dry the part.

使用低压气枪配合洁净干燥的无油空气干燥零件。

(13) Visually inspect the part surface to make sure all of the abrasive has been removed.

目视检查零件表面,确保所有研磨剂已被清除。

(14) Alternatively, ultrasonic cleaning can be used to remove the particulates.

也可采用超声波清洗去除颗粒物。

(15) Refer to Storage & Preservation, Chapter 16, for instructions to apply finger print neutralizer per MIL-C-15074 and/or additional preservation.

参照第16章《储存与保养》中关于按MIL-C-15074标准使用指纹中和剂及/或额外保养措施的说明。

清洁程序

A. Task 1: Flush Partially Assembled Jet Fuel Controls

任务1:冲洗半组装状态的喷气燃料控制装置

WARNING: JET FUEL IS TOXIC AND FLAMMABLE. DO NOT BREATHE VAPORS. USE IN WELL-VENTILATED AREA FREE FROM SPARKS, FLAME, OR HOT SURFACES. PUT ON SPLASH GOGGLES, SOLVENT-RESISTANT GLOVES, AND OTHER PROTECTIVE GEAR. IN CASE OF EYE CONTACT, FLUSH WITH WATER FOR 15 MINUTES AND SEEK MEDICAL ATTENTION. IN CASE OF SKIN CONTACT, WASH WITH SOAP AND WATER.

警告:喷气燃料具毒性且易燃。切勿吸入蒸汽。须在通风良好且远离火花、明火或高温表面的区域操作。佩戴防溅护目镜、耐溶剂手套及其他防护装备。若溅入眼睛,立即用清水冲洗15分钟并就医;若接触皮肤,用肥皂水清洗。

(1) Put partially assembled fuel control with open face down on fixture or hang on hook in flushing compartment of the flushing rig.

将部分组装好的燃油控制装置敞口朝下放置于冲洗架固定装置上,或悬挂于冲洗装置冲洗舱的挂钩上。

(2) Flush internal area of fuel control with upward stream of pressurized MIL-C-7024D, Type II calibrating fluid for 1 to 3 minutes.

用向上喷射的加压MIL-C-7024D II型校准液冲洗燃油控制装置内部区域,持续1至3分钟。

(3) Flush external area with horizontal stream of pressurized fuel for 1 to 3 minutes.

用水平喷射的加压燃油冲洗外部区域,持续1至3分钟。

(4) Shut off the pressurized stream of fuel.

关闭加压燃油流。

(5) Drain the partially assembled fuel control over the flushing compartment of the flushing rig.

将部分组装好的燃油控制装置置于清洗装置的冲洗舱上方进行排水。

B. Task 2: Cleaning Electrical Components

任务2:电气元件清洁

(1) Procedure 1: External Surfaces

程序1:外部表面

WARNING: USE GOGGLES AND RUBBER GLOVES WHEN YOU USE LPS NOFLASH CLEANER. USE IT IN AN AREA WITH A GOOD FLOW OF AIR. IT CAN CAUSE IRRITATION TO YOUR EYES, SKIN AND RESPIRATORY TRACT.

警告:使用LPS无闪光清洁剂时须佩戴护目镜和橡胶手套。操作需在通风良好的区域进行。该清洁剂可能刺激眼睛、皮肤及呼吸道。

(a) Wipe the external surface of the electrical component with a clean, lint-free cloth moistened with LPS NoFlash Cleaner or equivalent.

用浸有LPS NoFlash清洁剂或同等产品的无绒布擦拭电气元件外部表面。

(b) Use a low pressure air gun with clean, dry, oil-free air to dry the electrical components.

使用低压气枪以清洁干燥的无油空气吹干电气元件。

(2) Procedure 2: Clean Electrical Connectors

程序2:电气连接器清洁

WARNING: USE ISOPROPYL ALCOHOL, TT-I-735 OR ASTM D770, CORRECTLY. ISOPROPYL ALCOHOL IS FLAMMABLE, EXPLOSIVE, AND A MILD POISON. IT CAN HAVE A BAD EFFECT ON YOUR HEALTH OR SAFETY. BEFORE YOU USE THE ISOPROPYL ALCOHOL, GET THE MATERIAL SAFETY DATA SHEET FROM THE MANUFACTURER OR SUPPLIER OF THE MATERIAL AND READ IT CAREFULLY. READ THE DETAILED WARNING, W0046SE, IN THE WARNINGS REGISTRY SPM 20-00-04. BEFORE YOU USE THE ISOPROPYL ALCOHOL, PUT ON CHEMICAL-SPLASH GOGGLES. MAKE SURE THAT YOU HAVE SUFFICIENT AIRFLOW TO KEEP THE ISOPROPYL ALCOHOL FUMES BELOW THE MATERIAL SAFETY DATA SHEET LIMIT.

警告:正确使用异丙醇(TT-I-735或ASTM D770标准)。异丙醇具有易燃、易爆特性,属轻度毒性物质,可能危害健康与安全。使用异丙醇前,请向制造商或供应商索取材料安全数据表并仔细阅读。请查阅警告登记册SPM 20-00-04中的详细警示W0046SE。使用异丙醇前务必佩戴防化学溅射护目镜。确保通风充足,使异丙醇蒸气浓度低于安全数据表限定值。

(a) Put a non-metallic bristle brush or swab into isopropyl alcohol momentarily. Use the brush to clean the surfaces, the pins and the sockets of the electrical connectors.

将非金属毛刷或棉签短暂浸入异丙醇中。用刷子清洁电气连接器的表面、插针及插座。

WARNING: WHEN YOU USE COMPRESSED AIR TO CLEAN OR DRY PARTS, MAKE SURE THAT THE PRESSURE IS NOT MORE THAN 30 POUNDS PER SQUARE INCH (206.8 KILOPASCALS). DO NOT DIRECT THE AIRSTREAM AT PERSONNEL OR LIGHT OBJECTS. PUT ON GOGGLES OR A FACE SHIELD TO PROTECT YOUR EYES. THIS WILL HELP TO PREVENT INJURIES TO PERSONNEL OR DAMAGE TO THE EQUIPMENT. IF YOU HAVE AN EYE INJURY, GET MEDICAL ATTENTION.

警告:使用压缩空气清洁或干燥零件时,确保压力不超过每平方英寸30磅(206.8千帕)。切勿将气流直接吹向人员或易燃物体。佩戴护目镜或面罩保护眼睛,此举可有效避免人员受伤或设备损坏。若发生眼部损伤,请立即就医。

(b) Use a low pressure air gun with clean, dry, oil-free air to dry the electrical connectors.

使用低压气枪,以清洁干燥的无油压缩空气吹干电气连接器。

C. Task 3: Remove Surface Rust from Steel Parts

任务3:清除钢制零件表面锈迹

NOTE: Use the procedure that follows to remove surface rust.

注意:请按以下程序清除表面锈迹。

(1) Refer to Chapter 300 CLEANING, Section 4, Task 1, to clean the part.

参照第300章清洁规范第4节任务1进行零件清洁。

NOTE: Bear-Tex is a coarse abrasive material that is used to remove a large quantity of material, depending on the grade of Bear-Tex used. Scotch-Brite is a fine abrasive material that is used to remove a smaller quantity of material than will be removed with the Bear-Tex.

注:Bear-Tex是一种粗磨料,根据所用Bear-Tex的等级不同,可去除大量材料。Scotch-Brite是一种细磨料,其去除材料的量少于Bear-Tex。

(2) Rub Bear-Tex or Scotch-Brite on the area of the part that has the surface rust.

用Bear-Tex或Scotch-Brite擦拭零件表面锈蚀区域。

NOTE: Rust can also be removed with commercial acidic liquids such as RustEater, Turtle Rust Remover, or phosphoric acid. If used, neutralize with mild alkaline solution such as 2% sodium carbonate or sodium hydroxide, then rinse well in potable water, and dry quickly.

注:也可使用市售酸性液体(如RustEater除锈剂、Turtle除锈剂或磷酸)清除锈迹。若采用此法,需用2%碳酸钠或氢氧化钠等弱碱溶液中和,随后用饮用水充分冲洗并快速干燥。

(3) Use a low pressure air gun with clean, dry oil-free air to remove any loose particle.

使用低压气枪吹除松动颗粒,确保使用清洁干燥的无油压缩空气。

(4) Examine the area to make sure there is no surface rust.

检查该区域,确保无表面锈迹。

(5) If the rust is not fully removed, then repeat steps (2) thru (4).

若锈迹未完全清除,则重复步骤(2)至(4)。

(6) Replace the part if there are any pits exceeding limits specified in the CMM.

若存在超过CMM规定限值的凹坑,则更换零件。

D. Task 4: Procedure to Clean Small Surface Areas

任务4:小面积表面清洁程序

WARNING: USE ISOPROPYL ALCOHOL, TT-I-735 OR ASTM D770, CORRECTLY. ISOPROPYL ALCOHOL IS FLAMMABLE, EXPLOSIVE, AND A MILD POISON. IT CAN HAVE A BAD EFFECT ON YOUR HEALTH OR SAFETY. BEFORE YOU USE THE ISOPROPYL ALCOHOL, GET THE MATERIAL SAFETY DATA SHEET FROM THE MANUFACTURER OR SUPPLIER OF THE MATERIAL AND READ IT CAREFULLY. READ THE DETAILED WARNING, W0046SE, IN THE WARNINGS REGISTRY SPM 20-00-04. BEFORE YOU USE THE ISOPROPYL ALCOHOL, PUT ON CHEMICAL-SPLASH GOGGLES. MAKE SURE THAT YOU HAVE SUFFICIENT AIRFLOW TO KEEP THE ISOPROPYL ALCOHOL FUMES BELOW THE MATERIAL SAFETY DATA SHEET LIMIT.

警告:正确使用异丙醇(TT-I-735或ASTM D770标准)。异丙醇具有易燃、易爆特性,且为轻度毒物,可能危害健康与安全。使用异丙醇前,须向制造商或供应商索取材料安全数据表并仔细阅读。请查阅警告登记册SPM 20-00-04中的详细警告W0046SE。使用异丙醇前,请佩戴防化学溅射护目镜。确保通风充足,使异丙醇蒸气浓度维持在安全数据表限定值以下。

(1) You can use one of the steps that follows to clean the surface of the part:

可采用以下任一步骤清洁零件表面:

(a) Put a non-metallic bristle brush or swab into isopropyl alcohol momentarily. Rub the surface of the part with the brush. Use a clean, lint-free cloth to wipe the surface of the part.

将非金属刷毛刷或棉签短暂浸入异丙醇中。用刷子擦拭零件表面。使用干净无绒布擦拭零件表面。

(b) Wipe the external surface of the part with a clean, lint-free cloth moistened with isopropyl alcohol.

用浸有异丙醇的干净无绒布擦拭零件外部表面。

(c) You can also use Bear-Tex or Scotch-Brite.

也可使用Bear-Tex或Scotch-Brite清洁剂。

WARNING: WHEN YOU USE COMPRESSED AIR TO CLEAN OR DRY PARTS, MAKE SURE THAT THE PRESSURE IS NOT MORE THAN 30 POUNDS PER SQUARE INCH (206.8 KILOPASCALS). DO NOT DIRECT THE AIRSTREAM AT PERSONNEL OR LIGHT OBJECTS. PUT ON GOGGLES OR A FACE SHIELD TO PROTECT YOUR EYES. THIS WILL HELP TO PREVENT INJURIES TO PERSONNEL OR DAMAGE TO THE EQUIPMENT. IF YOU HAVE AN EYE INJURY, GET MEDICAL ATTENTION.

警告:使用压缩空气清洁或干燥零件时,确保压力不超过30磅/平方英寸(206.8千帕)。切勿将气流直接对准人员或易燃物体。佩戴护目镜或面罩保护双眼。此举可有效避免人员受伤或设备损坏。若发生眼部损伤,请立即就医。

(d) Use a low pressure air gun with clean, dry oil-free air to dry the electrical connectors.

使用低压气枪配合洁净干燥的无油压缩空气干燥电气连接器。

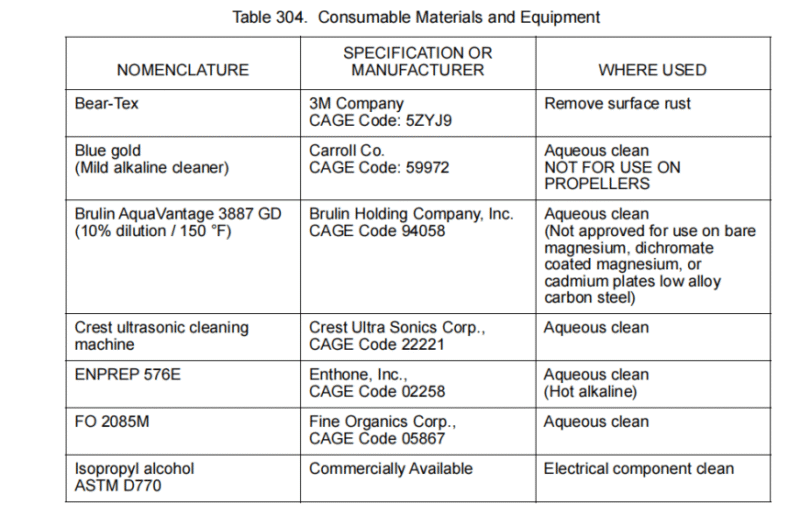

消耗品

NOTE: Maintenance personnel must use the specified consumable material for the specified task. These consumable materials are known to agree with all of the design and qualification requirements. Only approved materials engineering personnel can make equivalent consumable material decisions. These materials are used at the risk of the organization who makes the decision.

注:维护人员必须使用指定任务的专用消耗材料。这些材料已通过所有设计与认证要求验证。仅经批准的材料工程人员可决定使用等效消耗材料,相关决策风险由决策组织自行承担。

NOTE: You can get the full address and other information for vendors or suppliers listed in this table from the World Wide Web (www) at URL http://www.logisticsinformationservice.dla.mil. Other CAGE Code sites are also available on the Web.

注:本表所列供应商的完整地址及其他信息可通过万维网(www)访问网址 http://www.logisticsinformationservice.dla.mil 获取。其他CAGE代码网站同样可在网络上查阅。

![图片[1]-清洁 二 CLEANING-航修札记](https://www.aeroacm.com/wp-content/uploads/2026/01/20260119224703780-image.png)

![图片[2]-清洁 二 CLEANING-航修札记](https://www.aeroacm.com/wp-content/uploads/2026/01/20260119224712129-image.png)

暂无评论内容