CAUTION: DO NOT USE THE MECHANICAL STANDARD PRACTICES MANUAL BY ITSELF. USE IT ONLY AS SPECIFIED IN THE APPLICABLE COMPONENT MAINTENANCE MANUAL OR OTHER FAA-APPROVED DOCUMENTS.

注意:请勿单独使用《机械标准操作手册》。仅可依据适用部件维护手册或其他联邦航空管理局批准文件中的规定使用。

通用数据

A. The reasons to clean hardware are as follows:

清洁硬件的原因如下:

• To permit a full check of components for the presence of service defects or a change in dimensions through abrasion and wear.

便于全面检查零件是否存在使用缺陷或因磨损导致的尺寸变化。

• To prepare the surface of the part for the application of a repair, a coat (other than adhesives), weld, or a paint process. Each adhesive will specify its own cleaning method for preparation.

为零件表面进行修复、涂层(粘合剂除外)、焊接或喷漆处理做准备。每种粘合剂均有其特定的清洁准备方法。

• To remove deposits, including rust, which can cause the parts not to operate correctly.

清除可能导致零件失效的沉积物(包括锈蚀)。

• To remove used coats that can cause the parts not to operate correctly.

去除可能影响零件正常运作的旧涂层。

B. Once clean, parts should be moved to and stored in a clean and dry room. Use extreme care to prevent the entrance of foreign material and/or corrosion.

清洁完毕的零件应转移至洁净干燥的房间存放。务必严防异物侵入及腐蚀发生。

C. After disassembly, thoroughly clean and dry all parts to permit thorough inspection to determine whether parts are serviceable or repairable. The paragraphs that follow give specific procedures to clean the parts.

拆卸后须彻底清洁并干燥所有零件,以便全面检验其是否具备使用价值或可修复性。以下段落提供零件清洁的具体操作程序。

WARNING: REFER TO THE MANUFACTURER’S MATERIAL SAFETY DATA SHEETS FOR CONSUMABLE MATERIAL INFORMATION SUCH AS: HAZARDOUS INGREDIENTS PHYSICAL/CHEMICAL CHARACTERISTICS FIRE, EXPLOSION, REACTIVITY, AND HEALTH HAZARD DATA, PRECAUTIONS FOR SAFE HANDLING USE AND CONTROL MEASURES.

警告:消耗性材料信息请参阅制造商的安全数据表,包括:危险成分、物理/化学特性、火灾/爆炸风险、反应性、 及健康危害数据、安全操作注意事项与控制措施。

CAUTION: HANDLE PARTS HAVING HIGHLY FINISHED SURFACES WITH EXTREME CARE TO AVOID DAMAGE. CLEAN ONLY A SMALL NUMBER OF PARTS AT ONE TIME, USING A COMPARTMENTED CONTAINER.

注意:处理表面精加工的零件时须格外小心避免损伤。每次仅清洁少量零件,并使用分隔容器。

NOTE: Titanium and titanium alloy must be cleaned only in alkaline solution.

注意:钛及钛合金部件仅可使用碱性溶液清洗。

D. Compressed air used for cleaning and drying must not exceed 30 PSIG as required by the Occupational Safety and Health Administration (Federal Register, Part 2, 1910.242 General, Paragraph B.).

清洗干燥用压缩空气压力不得超过30PSIG,此要求依据美国职业安全与健康管理局规定(联邦公报第2零件1910.242条通用条款B款)。

CAUTION: TANKS USED TO CLEAN PARTS MUST NOT BE USED TO STRIP PARTS. TANKS USED TO STRIP PARTS MUST NOT BE USED TO CLEAN PARTS.

警告:用于零件清洗的槽罐严禁用于零件剥离处理,反之亦然。

E. Because of the environmental and health concerns, VAPOR DEGREASING will no longer be specified in new/revised manual publications. Aqueous clean procedure is recommended in its place.

鉴于环境与健康考量,新版/修订版手册将不再指定使用蒸汽脱脂法,建议改用水性清洗程序。

F. Hamilton Sundstrand no longer recommends chlorinated solvents, such as trichlorethane.

HS公司不再推荐使用氯化溶剂(如三氯乙烷)。

零件清洗程序的选择

A. Selection of materials and processes to clean parts as specified in the component maintenance manual is dependent on:

根据部件维护手册规定的清洗材料与工艺选择,需依据以下因素:

• The contaminant to be removed.

待清除的污染物类型

• The type of material coating and surface finish of the part to be cleaned.

被清洗零件的材料涂层类型及表面处理状态

• The degree of cleanliness required for a full inspection and subsequent repair process.

完整检测及后续维修流程所需的清洁度等级

B. The procedure to clean a part must meet the requirements that follow:

零件清洁程序须满足以下要求:

• The method must clean parts sufficiently so that a correct inspection by recommended processes is possible.

清洁方法必须充分清除污染物,以确保通过推荐流程进行正确检查。。

• The procedure to clean a part must not change the dimensions or damage the coating or surface finish of the parts.

清洁程序不得改变零件尺寸或损伤涂层/表面处理。

C. To avoid unnecessary cleaning, follow these instructions:

避免不必要清洁的指导原则:

• It is not necessary to remove stains from cadmium and nickel-cadmium plated parts.

无需清除镉镀层及镍镉镀层零件上的污渍。

• It is not necessary to remove coatings unless a part must have critical penetrant inspection.

除非零件必须进行关键渗透检测,否则无需清除涂层。

• It is not necessary to strip paints and varnishes on aluminum or magnesium parts unless the penetrant inspection can not be performed.

除非无法实施渗透检测,否则铝或镁零件上的油漆和清漆无需剥离。

水性清洗程序

A. General Aqueous Process Information

水性工艺通用信息

(1) Do not put electrical devices in the aqueous solution.

电气设备不得浸入水溶液。

(2) Do not put any of the listed hardware in the aqueous solution:

下列硬件不得浸入水溶液:

• Part assemblies

零件组件

• Bellows

波纹管

• Sintered metals

烧结金属

• Parts that have dry film lubricant, such as Electrofilm, on them.

表面附有干膜润滑剂(如Electrofilm)的零件

• Carbon bushings.

碳衬套

(3) Aqueous cleaners are intended for oil and grease removal from metal parts.

水性清洗剂仅适用于清除金属零件上的油脂。

(4) Aqueous cleaners are not intended to remove buffing compounds, adhered solids, or similar contaminants from parts.

水性清洗剂不适用于清除抛光膏、附着固体或类似污染物。

(5) If they are rustproof, matched valves can be cleaned with aqueous cleaner but the spool and the sleeve must be kept separate.

防锈活门可使用水基清洗剂清洁,但滑阀与阀套必须分开处理。

(6) Materials such as glass and plastics can be cleaned by this process.

玻璃、塑料等材料可通过此工艺清洁。

(7) Parts can be suspended in the aqueous cleaner in baskets, hooks, nylon slings, or cable slings.

零件可悬挂于水基清洗剂中,使用篮筐、挂钩、尼龙吊带或钢缆吊带。

(8) Do not use manila slings, canvas slings, or hemp rope to suspend baskets because exposure weakens them.

禁止使用麻绳吊带、帆布吊带或麻绳悬挂篮筐,因浸泡会导致其强度降低。

(9) Position the parts so that the cleaning liquid does not become trapped in the part.

零件应摆放妥当,避免清洗液滞留于零件内部。

(10) Covers or lids of aqueous clean equipment must be kept closed when not in use.

水性清洗设备闲置时必须保持盖板或顶盖关闭。

(11) Turn off the aqueous clean equipment if the equipment will not be in operation for several hours to extend the life of the equipment.

若设备停用数小时,应关闭电源以延长设备寿命。

(12) The operator must check the parts to make sure they are fully clean, dry, and visually free of all chips and foreign material after cleaning.

操作员必须检查零件,确保清洗后完全清洁、干燥,且肉眼可见无任何碎屑和异物。

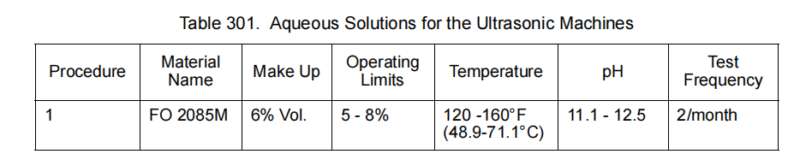

(13) Refer to Table 301 for the correct aqueous solution.

正确的水溶液配方请参见表301。

B. Task 1: Ultrasonic Clean That Uses Aqueous Solutions

任务1:使用水溶液的超声波清洗

WARNING: DO NOT PUT YOUR HANDS INTO THE TANK. IT CAN CAUSE DAMAGE TO YOUR SKIN.

警告:切勿将手伸入清洗槽,可能导致皮肤损伤。

NOTE: A machine that uses high frequency sound (ultrasonic) waves to agitate the solution which in turn cleans the parts. It is important to position parts to take advantage of sound waves.

注:本设备利用高频声波(超声波)振荡溶液实现零件清洗。需合理定位零件以充分利用声波作用。

(1) Use a Crest Ultrasonic or equivalent machine to clean the parts. The ultrasonic frequency shall be 38 kHz minimum.Refer to the manufacturer’s user instructions to correctly operate the ultrasonic clean machine.

使用Crest超声波清洗机或同等设备进行零件清洗。超声频率不低于38千赫兹。请参照制造商操作说明正确使用超声波清洗机。

(2) Refer to Table 301 for the recommended temperatures and solutions.

推荐温度及溶液配方详见表301。

NOTE: Maintenance personnel must use the specified consumable material for the specified task. These consumable materials are known to agree with all of the design and qualification requirements. Only approved materials engineering personnel can make equivalent consumable material decisions. These materials are used at the risk of the organization who makes the decision.

注意:维护人员必须使用指定耗材执行指定任务。这些耗材已通过所有设计与资质要求验证。仅经批准的材料工程师可决定使用等效耗材,使用风险由决策单位自行承担。

![图片[1]-清洁 一 CLEANING-航修札记](https://www.aeroacm.com/wp-content/uploads/2025/12/20251213233327923-word-image-11497-1.png)

(3) Make sure all of the tanks are at the correct temperature before the procedure to clean the parts is started.

启动零件清洗程序前,确保所有清洗槽均达到正确温度。

(4) Position the parts in trays or baskets so they can drain unwanted fluid into the tank.

将零件置于托盘或篮筐中,使其多余液体能流入清洗槽。

CAUTION: TO PREVENT DAMAGE, MAKE SURE PARTS DO NOT COME INTO METAL TO METAL CONTACT WITH OTHER PARTS OR THE PROCESSING EQUIPMENT. USE ONLY PLASTIC OR PLASTIC COATED BASKETS OR SEPARATORS.

注意:为防止损坏,确保零件与其他零件或处理设备之间不发生金属间接触。仅使用塑料或塑料涂层篮筐/隔板。

(5) Put the parts fully into the cleaning solution tank and turn on the ultrasonic power.

将零件完全浸入清洗液槽中,开启超声波电源。

(6) Keep the power on for 3 to 5 minutes. For aluminum parts, move them periodically to prevent pitting.

持续通电3至5分钟。铝制零件需定期移动以防点蚀。

(7) Remove the parts from the solution.

从溶液中取出零件。

WARNING: WEAR PROTECTIVE GLOVES AND AN APRON WHEN HANDLING PARTS TO AVOID DAMAGE TO YOUR SKIN.

警告:处理零件时务必佩戴防护手套和围裙,避免皮肤损伤。

(8) Drain the parts fully over the tank.

将零件置于槽体上方彻底沥干。

(9) If soil remains on the part after one cleaning cycle, repeat steps (4) through (8).

若单次清洗后零件仍有污垢残留,请重复步骤(4)至(8)。

(10) Put the parts fully into the first rinse tank.

将零件完全浸入第一道冲洗槽。

(11) Turn on ultrasonic power for 3 to 5 minutes. For aluminum parts, move them periodically to prevent pitting.

启动超声波电源3至5分钟。铝制零件需定期移动以防点蚀。

(12) Remove the parts from the solution.

从溶液中取出零件。

(13) Drain the parts fully over the tank.

将零件置于槽体上方彻底沥干。

WARNING: WHEN YOU USE COMPRESSED AIR TO CLEAN OR DRY PARTS, MAKE SURE THAT THE PRESSURE IS NOT MORE THAN 30 POUNDS PER SQUARE INCH (206.8 KILOPASCALS). DO NOT DIRECT THE AIRSTREAM AT PERSONNEL OR LIGHT OBJECTS. PUT ON GOGGLES OR A FACE SHIELD TO PROTECT YOUR EYES. THIS WILL HELP TO PREVENT INJURIES TO PERSONNEL OR DAMAGE TO THE EQUIPMENT. IF YOU HAVE AN EYE INJURY, GET MEDICAL ATTENTION.

警告:使用压缩空气清洁或干燥零件时,确保压力不超过每平方英寸30磅(206.8千帕)。切勿将气流直接吹向人员或易燃物体。佩戴护目镜或面罩保护眼睛。此举可有效避免人员受伤或设备损坏。若发生眼部损伤,请立即就医。

(14) Use a low pressure air gun with clean, dry, oil-free air to remove any solution caught in the part.

使用低压气枪,以洁净干燥的无油空气清除零件内残留的溶液。

(15) Remove the parts from the basket.

从篮筐中取出零件。

(16) Dry to remove all visible moisture.

干燥以去除所有可见水分。

(17) Take the parts out of the drying chamber. Visually inspect the parts for the absence of residual moisture.

从干燥室取出零件。目视检查零件是否存在残留水分。

(18) If the parts can resist the temperature, dry them at 160 deg F. Otherwise, place parts with blind passages into a vacuum drying chamber for 5-15 minutes, at a minimum reading of 25 inches Hg, as indicated by the vacuum gage, to remove all remaining moisture. Repeat procedure if necessary.

若零件耐受该温度,可于160华氏度(71摄氏度)环境中干燥;否则需将带盲孔的零件置于真空干燥室,在真空表显示至少25英寸汞柱(25 in Hg)的条件下干燥5-15分钟,彻底清除残留水分。必要时重复操作。

C. Task 2: Pressure Washer That Uses Aqueous Solutions

任务2:使用水溶液的压力清洗机

(1) Before washing, parts should be wiped to remove excess grease, oil, dirt, etc.

清洗前需擦拭零件表面,清除多余油脂、油污、泥垢等。

(2) Position the parts in the applicable basket or fixture to prevent metal to metal contact.

将零件置于适配篮筐或夹具中,避免金属间直接接触。

CAUTION: TO PREVENT DAMAGE, MAKE SURE PARTS DO NOT COME INTO METAL-TO-METAL CONTACT WITH OTHER PARTS OR THE PROCESSING EQUIPMENT. USE ONLY PLASTIC OR PLASTIC-COATED BASKETS OR SEPARATORS.

注意:为防止损坏,确保零件与其他部件或加工设备间无金属直接接触。仅使用塑料或塑料涂层篮筐/隔板。

(3) Position the basket or fixture in the pressure washer.

将篮筐或夹具放入高压清洗机。

(4) Refer to Table 302 for the recommended temperatures and solutions.

参照表302选择推荐温度及溶液。

(5) For aluminum parts, move them periodically to prevent pitting.

铝制零件需定期移动以防点蚀。

NOTE: Maintenance personnel must use the specified consumable material for the specified task. These consumable materials are known to agree with all of the design and qualification requirements. Only approved materials engineering personnel can make equivalent consumable material decisions. These materials are used at the risk of the organization who makes the decision.

注:维护人员必须使用指定任务的专用耗材。这些耗材已通过所有设计与资质要求验证。仅经批准的材料工程人员可决定使用等效耗材,相关组织需自行承担使用风险。

![图片[2]-清洁 一 CLEANING-航修札记](https://www.aeroacm.com/wp-content/uploads/2025/12/20251213233328169-word-image-11497-2.png)

(6) If the pressure washer has a center nozzle, make sure there is clearance for the center nozzle to move through the middle of the parts.

若高压清洗机配备中心喷嘴,确保其在零件中央移动时留有足够间隙。

(7) Make sure that all of the parts are secure and that they do not touch each other.

确保所有零件固定稳固且互不接触。

(8) Close the pressure washer door.

关闭高压清洗机门。

(9) Make sure the tanks are at the correct temperature.

确认储液罐处于正确温度。

(10) Make sure the chip screens are clear of debris.

确保切屑过滤网无杂物堵塞。

(11) Refer to the manufacturer’s user instructions to correctly operate the pressure washer machine.

参照制造商使用说明正确操作高压清洗机。

(12) Use the data that follows to adjust the cycle time:

依据下列数据调整清洗周期:

(a) The size of the load to be cleaned.

待清洗工件的尺寸。

(b) The amount of contamination on the parts.

零件上的污染程度。

(13) After the cycle finish is complete:

循环结束后:

WARNING: CAREFULLY OPEN THE PRESSURE WASHER DOOR BECAUSE HOT STEAM WILL EXIT THE WASHER. WEAR PROTECTIVE GLOVES WHEN YOU TOUCH THE PARTS.

警告:开启高压清洗机门时需谨慎操作,因高温蒸汽将从设备内逸出。接触零件时务必佩戴防护手套。

(a) Open the pressure washer door.

打开高压清洗机门。

(b) Inspect the parts to make sure they are clean.

检查零件确保清洁。

WARNING: WHEN YOU USE COMPRESSED AIR TO CLEAN OR DRY PARTS, MAKE SURE THAT THE PRESSURE IS NOT MORE THAN 30 POUNDS PER SQUARE INCH (207 KILOPASCALS). DO NOT DIRECT THE AIRSTREAM AT PERSONNEL OR LIGHT OBJECTS. PUT ON GOGGLES OR A FACE SHIELD TO PROTECT YOUR EYES. THIS WILL HELP TO PREVENT INJURIES TO PERSONNEL OR DAMAGE TO THE EQUIPMENT. IF YOU HAVE AN EYE INJURY, GET MEDICAL ATTENTION.

警告:使用压缩空气清洁或干燥零件时,确保压力不超过每平方英寸30磅(207千帕)。切勿将气流直接吹向人员或易燃物体。佩戴护目镜或面罩保护双眼。此举可有效避免人员受伤或设备损坏。若发生眼部损伤,请立即就医。

(14) If parts are adequately clean, remove them from pressure washer. Use a low pressure air gun with clean, dry oil-free air to remove any water.

若零件清洁度达标,将其移出高压清洗机。使用低压气枪配合洁净干燥的无油压缩空气吹除残留水分。

D. Task 3: Hot Alkaline Soak Using Orthosil F2

任务3:Orthosil F2热碱性浸泡

WARNING: CARE SHOULD BE TAKEN TO AVOID EYE AND SKIN CONTACT WHEN YOU CLEAN WITH ALKALI SOLUTIONS. SAFETY GOGGLES, GLOVES AND APRONS SHOULD BE WORN.

警告:使用碱性溶液清洗时,务必避免溶液接触眼睛和皮肤。必须佩戴安全护目镜、手套及防护围裙。

NOTE: Use this process to soak clean steel of any hardness, stainless steels, titanium, copper and brass. This process does not use electrolysis.

注:本工艺适用于浸泡清洁任何硬度的钢材、不锈钢、钛、铜及黄铜。此过程不涉及电解作用。

(1) You do not have to degrease the parts unless the parts are very oily.

除非零件严重油污,否则无需预先脱脂。

(2) Refer to Table 303 for the correct temperatures and solutions.

参照表303选择正确温度及溶液配比。

CAUTION: TO AVOID EXCESSIVE FOAMING WHEN MIXING SOLUTION, ORTHOSIL F2 MUST BE ADDED TO WATER AND NOT WATER INTO ORTHOSIL F2.

注意:为避免混合溶液时产生过量泡沫,必须将Orthosil F2加入水中,而非将水加入Orthosil F2。

![图片[3]-清洁 一 CLEANING-航修札记](https://www.aeroacm.com/wp-content/uploads/2025/12/20251213233328880-word-image-11497-3.png)

(3) Put the part fully into the hot alkali solution for 5 to 10 minutes until all deposits are removed from parts.

将零件完全浸入热碱溶液中5至10分钟,直至清除所有沉积物。

(4) Flush the part in a cold water rinse.

用冷水冲洗零件。

(5) Flush the part in a hot, 150-170F (66-77C), water rinse.

用150-170°F(66-77°C)热水冲洗零件。

WARNING: WHEN YOU USE COMPRESSED AIR TO CLEAN OR DRY PARTS, MAKE SURE THAT THE PRESSURE IS NOT MORE THAN 30 POUNDS PER SQUARE INCH (207 KILOPASCALS). DO NOT DIRECT THE AIRSTREAM AT PERSONNEL OR LIGHT OBJECTS. PUT ON GOGGLES OR A FACE SHIELD TO PROTECT YOUR EYES. THIS WILL HELP TO PREVENT INJURIES TO PERSONNEL OR DAMAGE TO THE EQUIPMENT. IF YOU HAVE AN EYE INJURY, GET MEDICAL ATTENTION.

警告:使用压缩空气清洁或干燥零件时,确保压力不超过30磅/平方英寸(207千帕)。切勿将气流直接吹向人员或易燃物体。佩戴护目镜或面罩保护眼睛。此举可避免人员受伤或设备损坏。若发生眼部损伤,请立即就医。

(6) Use a low pressure air gun with clean, dry oil-free air to remove any water.

使用低压气枪配合洁净干燥的无油压缩空气清除残留水分。

(7) Make sure parts are clean and dry.

确保零件清洁干燥。

暂无评论内容