3. Repair and Application of Protective Coatings and Plating

防护涂料及电镀的修复与应用

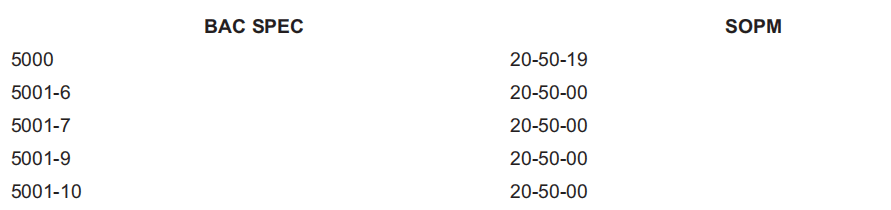

L.Method No. 403L: Repair of Paint Coatings Damaged Through Primer and Paint Topcoat, Exposing Bare Magnesium – Epoxy-Amine Systems

Method No. 403L:修复因底漆和面漆损坏而暴露裸露镁的油漆涂层-环氧胺体系

(1) Remove loose and chipped paint to bare metal.

清除松动和剥落的油漆,露出裸露的金属。

(2) Remove unwanted dust with dry clean compressed air.

用干燥清洁的压缩空气清除不需要的灰尘。

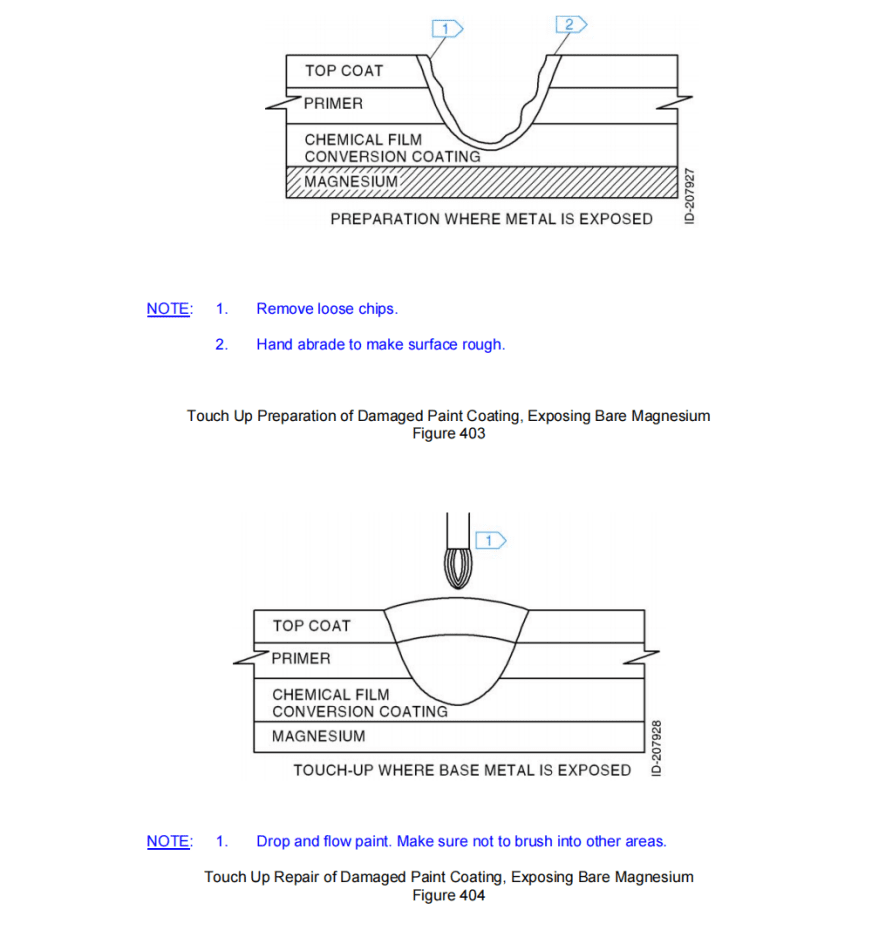

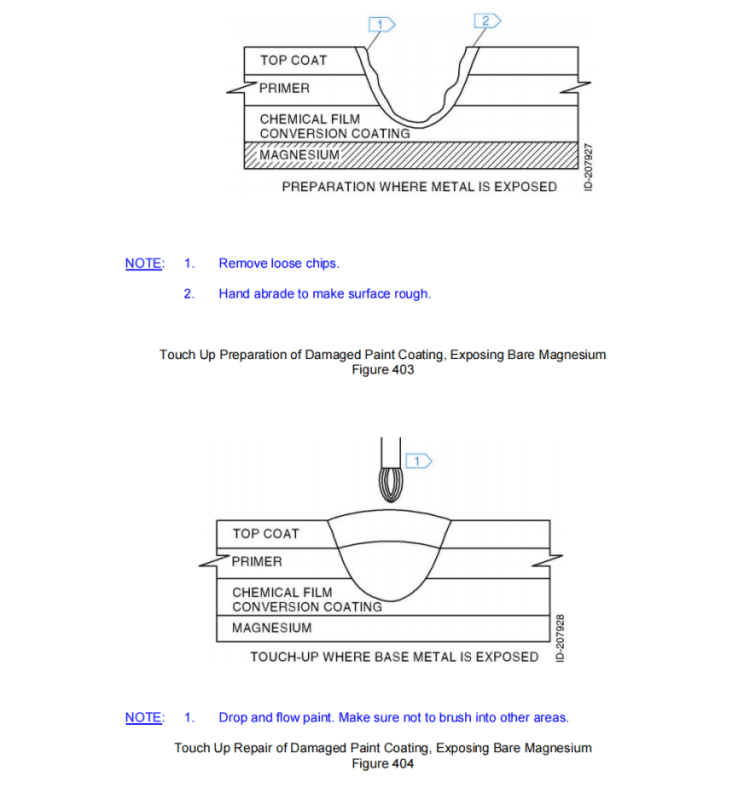

(3) Lightly hand abrade edges of paint to make surface rough. Use a 240-grit (wet-or-dry) abrasive paper C08-0021. Refer to Figures 403 and 404.

轻轻用手磨油漆边缘,使表面粗糙。使用240目(湿或干)砂纸C08-0021。参见图403和404。

(4) Use a cloth soaked with acetone C08-0005, or ketone C04-0003, to clean the surface to be repaired.

用浸有丙酮C08-0005或酮C04-0003的布清洁待修复表面。

WARNING: USE THE CORRECT PERSONAL PROTECTION. THIS CHEMICAL SOLUTION CAN CAUSE SKIN, EYE AND LUNG DAMAGE. THE DANGER AND PRECAUTIONS FOR EACH CHEMICAL IS DIFFERENT.

警告:使用正确的个人防护设备。这个化学品溶液可能造成皮肤、眼睛和肺部损伤。每种化学品的危险和注意事项不同。

(5) Chemical film touch up bare magnesium surfaces. Refer to Method No. 403O. Apply both Dow-1 and Dow-19 solutions.

化学薄膜修补裸露的镁表面。请参考Method No. 403O。同时使用Dow-1和Dow-19溶液。

CAUTION: POT LIFE OF MIXED MATERIALS IS 8 HOURS. ADHERE STRICTLY TO POT LIFE LIMIT OF MIX; MARK TIME AND DATE ON CUP. ABSOLUTELY DO NOT REFRIGERATE OR ADD SOLVENT TO EXTEND TIME.

注意:混合材料的罐装寿命为8小时。严格遵守混合材料的罐装寿命限制;在杯上标记时间和日期。绝对不要冷藏或添加溶剂以延长时间。

(6) Touch up damaged coatings with an airbrush or soft brush. Do not use cotton swabs. Airbrushing is the recommended method. Refer to Figures 403 and 404.

用喷雾器或软毛刷修补受损的涂层。请勿使用棉签。推荐采用喷雾器处理,参见图403和404。

(a) Refer to applicable manual for required primer and paint topcoat.

有关所需的底漆和面漆,请参考适用的手册。

(b) Mix base resin and catalyst thinner fully and let 45 minutes reaction time before you apply the mixture.

充分混合基础树脂和催化剂稀释剂,然后在涂覆混合物前等待45分钟的反应时间。

(c) Apply primer and paint topcoat. Refer to manufacturer recommendations.

涂底漆和面漆。请参考制造商建议。

NOTE: For mixture and cure of paint, refer to the applicable paint specification. Mix materials at room temperature (67 to 87°F (19 to 31°C)).

注:关于油漆的混合和固化,请参考适用的油漆规范。在室温(67 to 87°F (19 to 31°C))下混合材料。

(7) Dry painted part at room temperature for 60 minutes before curing of painted part.

在涂漆部件固化前,将干燥的涂漆部件在室温下放置60分钟。

(8) Cure paint with a heat gun.

用热风枪固化油漆。

(a) Let a 10 to 12 inch (254 to 305 mm) distance from the end of heat gun to the painted surface, at maximum temperature of 200˚F (93˚C).

在最高温度为200˚F(93˚C)时,使热风枪末端与被涂表面之间的距离为10至12英寸(254至305 mm)。

(b) Use heat during 30 to 45 minutes to cure part. Paint must be fully cured before packaging the part.

使用热固化零件30至45分钟。零件包装前必须确保油漆完全固化。

暂无评论内容