7.Replacing Inserts, Studs, Bushings, Pins and Nutplates

更换钢丝螺套、螺柱、衬套、销钉和螺母板

J.Method No. 407J: Loose, Worn or Damaged Nutplate (Welded) Replacement

Method No. 407J: 松动、磨损或损坏的螺母板(焊接式)更换

Replace loose, worn, or damaged welded nutplate as follows:

按以下步骤更换松动、磨损或损坏的焊接式螺母板:

(1) Replace nutplate with GTAW weld.

采用钨极惰性气体保护焊(GTAW)进行螺母板更换。

CAUTION: EXERCISE CARE NOT TO DAMAGE BASIC PART WHILE REMOVING RIVET.

注意:拆卸铆钉时务必小心,避免损坏基体零件。

(a) Remove damaged nutplates.

拆除损坏的螺母板。

(b) Procure new nutplates.

采购新螺母板。

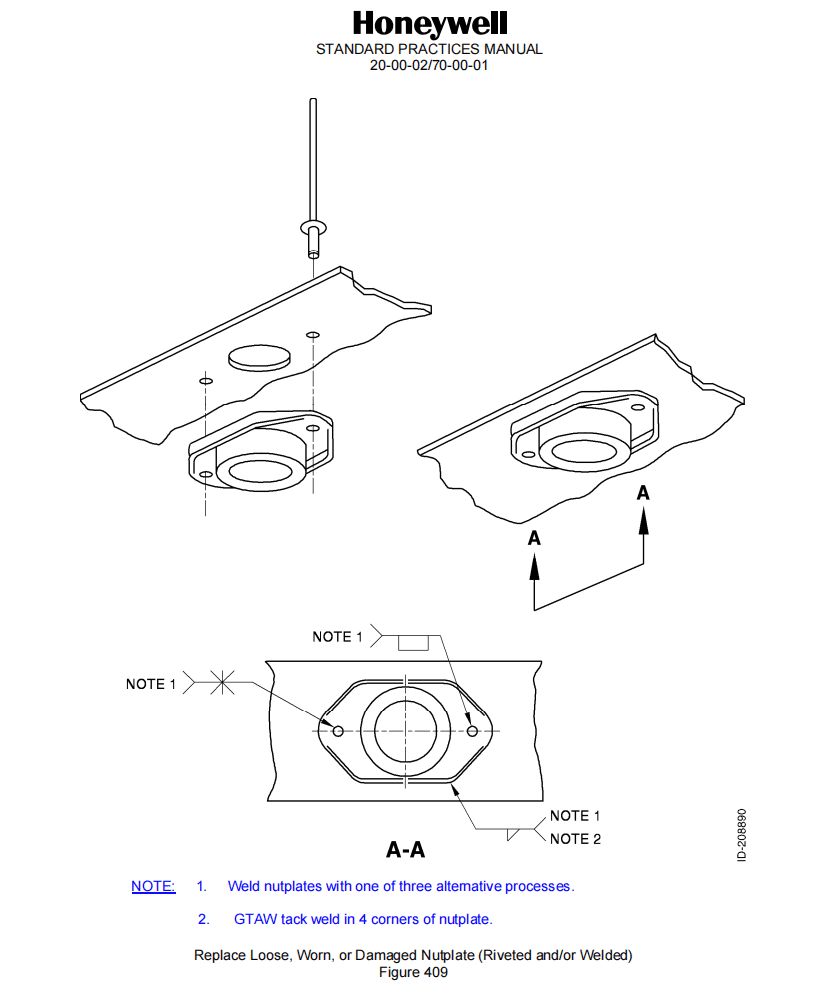

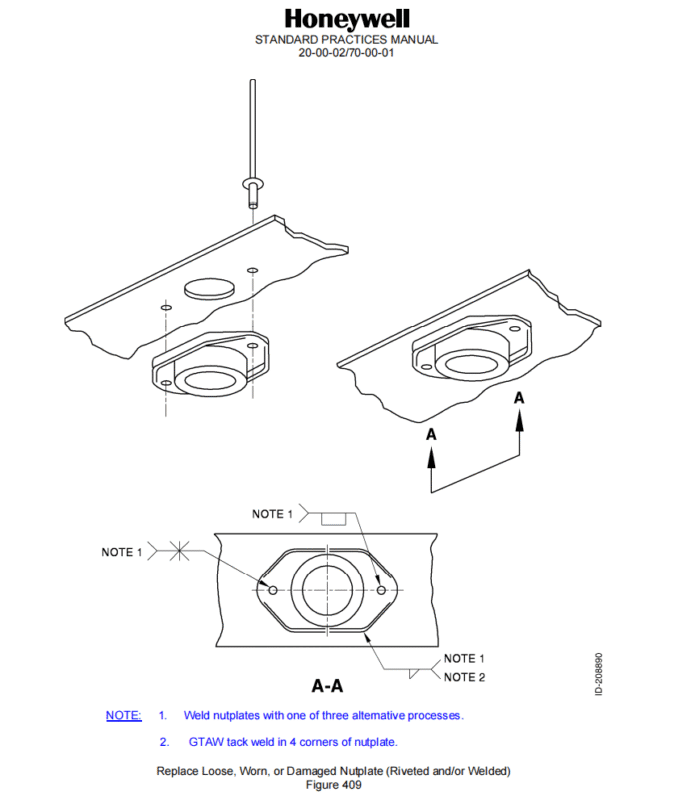

(c) Put nutplate in correct location as specified in applicable manual. Refer to Figure 409 as reference.

参照适用手册规定将螺母板安装至正确位置。参见图409作为参考。

(d) GTAW weld new nutplate. Refer to Method No. 411A, 411B, or 411C. Refer to Figure 409 as reference only.

对新螺母板进行GTAW焊接。参照方法编号411A、411B或411C。图409仅供参考。

CAUTION: AFTER WELDING, LET TEMERATURE OF THE PART SLOWLY DECREASE TO ROOM TEMERATURE.

注意:焊接后,需使零件温度缓慢降至室温。

1 GTAW weld nutplates with weld filler metal specified in applicable manual.

使用适用手册规定的焊料进行GTAW焊螺母板。

NOTE: Make sure nutplate is well aligned to original diameter.

注:确保螺母板与原始直径对齐良好。

2 Hand finish repaired surfaces.

手工修整修复表面。

(2) Replace nutplate with Resistance weld.

采用电阻焊更换螺母板。

CAUTION: EXERCISE CARE NOT TO DAMAGE BASIC PART WHILE REMOVING RIVET.

注意:拆卸铆钉时须小心避免损伤基体零件。

(a) Remove damaged nutplates.

拆除损坏的螺母板。

(b) Procure nutplates.

采购螺母板。

(c) Put nutplate in the correct location. Refer to Figure 409 as reference.

将螺母板置于正确位置。参照图409作为参考。

(d) Resistance weld new nutplates. Refer to AWSD17.2-D17.2M, Class C.

对新螺母板进行电阻焊。参照AWSD17.2-D17.2M, Class C 。

CAUTION: AFTER WELDING, LET TEMERATURE OF THE PART SLOWLY DECEASE TO ROOM TEMERATURE.

注意:焊接后需使零件温度缓慢降至室温。

1 Hand finish repaired surfaces.

手工修整修复表面。

NOTE: Make sure nutplate is well aligned to original diameter.

注:确保螺母板与原始直径对齐良好。

(3) Replace nutplate with GTAW tack weld.

采用钨极惰性气体保护焊(GTAW)点焊固定螺母板。

CAUTION: EXERCISE CARE NOT TO DAMAGE BASIC PART WILE REMOVING RIVET.

注意:拆除铆钉时务必小心,避免损坏基体零件。

(a) Remove damaged nutplates.

拆除损坏螺母板。

(b) Procure new nutplates.

采购新螺母板。

(c) Put nutplate in the correct location. Refer to Figure 409 as reference.

将螺母板置于正确位置。参照图409作为参考。

(d) GTAW tack weld new nutplates. Refer to Method No. 411A, 411B, or 411C. Refer to Figure 409 as reference only.

对新螺母板进行GTAW点焊。参照方法编号411A、411B或411C。图409仅供参考。

CAUTION: AFTER WELDING, LET TEMPERATURE OF THE PART SLOWLY DECREASE TO ROOM TEMPERATURE.

注意:焊接后,零件温度须缓慢降至室温。

1 GTAW tack weld nutplates in 4 corners of nutplate. Diameter tack and filler metal must be as specified in applicable manual.

在螺母板四角采用钨极惰性气体保护焊(GTAW)进行点焊。点焊直径及填充金属须符合相关手册规定。

NOTE: Make sure nutplate is well aligned to original diameter.

注:确保螺母板与原始直径对齐良好。

2 Hand finish repaired surfaces.

手工修整修复表面。

暂无评论内容