3. Repair and Application of Protective Coatings and Plating

防护涂料及电镀的修复与应用

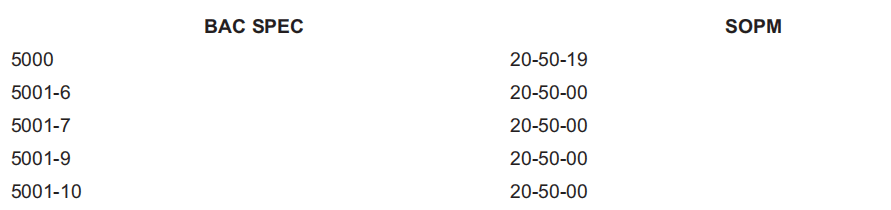

H.Method No. 403H: Silver Plating Repair

Method No. 403H:镀银修复

NOTE: If the type of silver plating is not specified in applicable manual, Type I, II, or III is acceptable.

注:如果适用手册中未规定银镀层类型,则I、II或III型均可接受。

NOTE: Plating thickness, unless otherwise specified in applicable manual, must be 0.0005 inch (0.013 mm) minimum on all surfaces on which silver is functionally necessary.

注:除非适用手册中另有规定,否则所有功能上需要银的表面的镀层厚度至少应为0.0005英寸(0.013 mm)。

Silver plating types:

银镀层类型

Type I – Matte Deposits without luster comparable to those normally obtained from silver-cyanide plating solutions operated with brighteners.

I类-无光泽的哑光沉积物,与使用增白剂的银氰化物电镀溶液通常获得的沉积物相当。

Type II – Semi-bright Semi-lustrous deposits comparable to those normally obtained from silver-cyanide plating solutions operated with brighteners.

II类-半光亮半光泽沉积物,与使用增白剂的氰化银电镀溶液中通常获得的沉积物相当。

Type III – Bright Sometimes obtained by polishing or by use of brightener.

III型-亮色,有时通过抛光或使用增白剂获得。

Silver plating grades:

银镀层等级

Grade A-With supplementary tarnish-resistant treatment (chromate treated).

A级-补充防变色处理(铬酸盐处理)。

Grade B-Without supplementary tarnish-resistant treatment. Repair silver plated parts as follows:

B级——未进行额外防变色处理。按如下方式修复镀银部件:

WARNING: USE THE CORRECT PERSONAL PROTECTION. PROCEDURES THAT NEED GRIND/MACHINE WORK WILL CAUSE LOOSE PARTICLES THAT CAN GET IN YOUR EYES.

警告:使用正确的个人防护设备。需要研磨/机械加工的程序会产生松散颗粒,可能进入眼睛。

(1) Machine surface to remove damage or all remaining plating. Surface finish must be 80 microinches (2 micrometers) or better.

机器表面以去除损坏或所有剩余的镀层。表面光洁度必须达到80微英寸(2微米)或更好。

NOTE: Make sure minimum stock material is removed. Do not machine more than the limits specified in applicable manual.

注:确保移除最低库存材料。请勿加工超过适用手册中规定的限制。

(2) Clean the part. Refer to SECTION II – CLEANING.

清洁零件。请参阅第II节-清洁。

(3) If necessary, perform magnetic particle or fluorescent penetrant inspection. No cracks are permitted. Refer to SECTION III – INSPECTION.

必要时,进行磁粉或荧光探伤检查。不允许存在裂纹。请参阅第III节——检验。

(4) Clean the part. Refer to SECTION II – CLEANING.

清洁部件。请参阅第II节-清洁。

(5) Mask all areas not to be silver plated.

遮盖所有非镀银区域。

CAUTION: WHEN THE BASE METAL IS ROCKWELL C40 OR HARDER, THE PART SHALL BE STRESS-RELIEVED AT 300˚F (149˚C) FOR TWO HOURS PRIOR TO PLATING.

注意:当基体金属为罗氏C40或更硬时,应在电镀前将零件在300˚F(149˚C)下进行应力消除处理两小时。

(6) Apply silver plating to surfaces of the part. Refer to ASTM B700, for necessary plating thickness.

在零件表面进行银镀,必要的镀层厚度请参考ASTM B700。

(7) Remove masking material.

移除遮蔽材料

WARNING: USE THE CORRECT PERSONAL PROTECTION. HEATED PARTS WILL CAUSE BURNS.

警告:使用正确的个人防护装置。加热零件会造成灼伤。

CAUTION: WHEN THE BASE METAL IS ROCKWELL C40 OR HARDER, THE PART MUST BE HYDROGEN-EMBRITTLEMENT-RELIEVED WITHIN FOUR HOURS AFTER PLATING.

注意:当基体金属为罗氏C40或更硬时,必须在电镀后四小时内对部件进行氢脆消除。

(8) Stress relieve silver plating on parts as follows. Refer to applicable manual.

零件上的应力消除电镀如下所示。请参阅适用手册。

(a) For parts with Rockwell C40-54 hardness, stress relieve for three hours at 365 to 385˚F (185 to 196˚C).

对于洛氏硬度为C40-54的零件,在365至385˚F(185至196˚C)下进行3小时的应力消除。

(b) For parts with Rockwell C55 and harder, stress relieve for five hours at 265 to 285˚F (129 to 141˚C).

对于采用洛氏C55或更硬的零件,需在265至285˚F(129至141˚C)下进行5小时的应力消除。

(9) Visually check plating for quality, coating thickness, roughness, adhesion, and solderability. Refer to ASTM B700.

目视检查电镀层的质量、涂层厚度、粗糙度、附着力和可焊性。参考ASTM B700。

(10) Store silver plated part in a container to prevent entrance of sulphur-bearing atmosphere.

将镀银零件存放在容器中,以防止含硫气氛进入。

暂无评论内容