分类

子分类

排序

HOEYWELL SECTION II – CLEANING 清洁(二)

2. Preparation of Cleaning Solutions 清洁溶液的配制 WARNING: SOLUTIONS USED FOR CLEANING ARE HAZARDOUS. AVOID INHALING FUMES, DUST, OR MIST. AVOID CONTACT WITH SKIN. AFTER PREPARAT...

SECTION IV – REPAIR 修理(二)-溶液制备

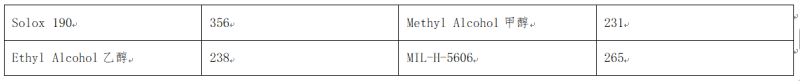

2.Preparation of Solutions溶液制备WARNING: SOLUTIONS USED FOR CLEANING ARE HAZARDOUS. AVOID INHALING FUMES, DUST, OR MIST. AVOID CONTACT WITH SKIN. AFTER PREPARATION, WASH HANDS AN...

SECTION III – INSPECTION 1. Standard Inspection Practices -H. Electrical Component Inspection电气组件检查

H. Electrical Component Inspection 电气组件检查CAUTION: REFER TO APPLICABLE MANUAL PRIOR TO PERFORMING ANY ELECTRICAL CHECKS TO ENSURE THAT CHECKS WILL NOT DAMAGE EQUIPMENT.注意:...

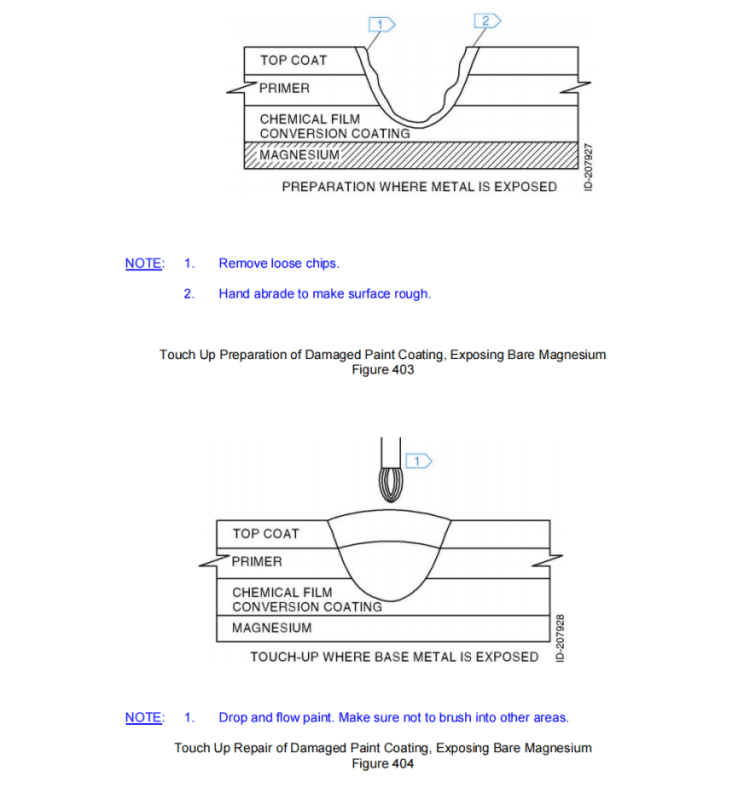

SECTION IV – REPAIR 修理(三)-L.Method No. 403L: Repair of Paint Coatings Damaged Through Primer and Paint Topcoat, Exposing Bare Magnesium – Epoxy-Amine Systems

3. Repair and Application of Protective Coatings and Plating 防护涂料及电镀的修复与应用L.Method No. 403L: Repair of Paint Coatings Damaged Through Primer and Paint Topcoat, Exposin...

SECTION IV – REPAIR 3. 防护涂料及电镀的修复与应用-C.Method No.403C:薄而致密的镀铬零件修复

3. Repair and Application of Protective Coatings and Plating 防护涂料及电镀的修复与应用C.Method No. 403C: Thin Dense Chrome Plated Parts RepairMethod No.403C:薄而致密的镀铬零件修...

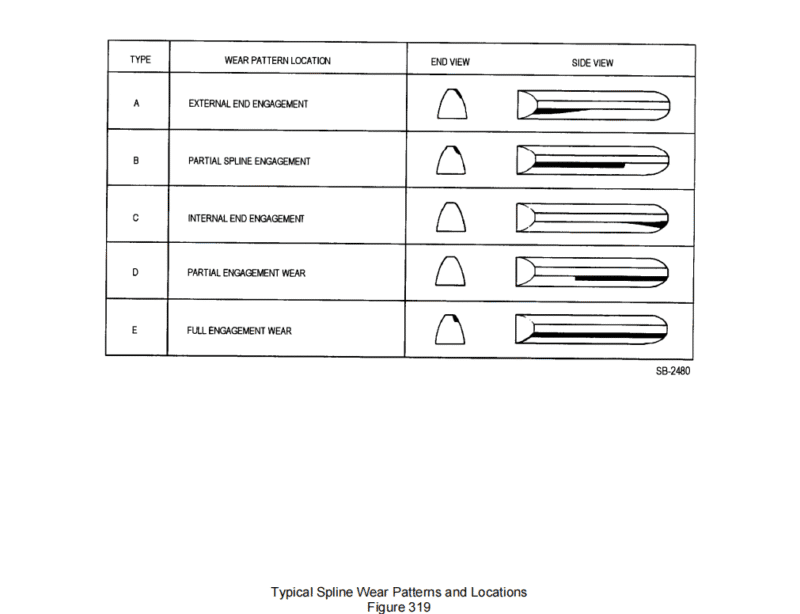

SECTION III – INSPECTION 检查(三)之齿轮和花键检查

F. Gear and Spline Inspection 齿轮和花键检查 (1) Check gear and spline teeth as follows: 检查齿轮和花键齿,如下所示: (a) Perform visual check using a strong light and a minimum of...

SECTION IV – REPAIR 5.清除钢制零件上的损伤-C.Method No. 405C: 使用玻璃珠喷丸修复密封直径(唇形密封面)

5.Removing Damage from Steel Parts清除钢制零件上的损伤C.Method No. 405C: Seal Diameter (Lip Seal Surface) Repair Using Glass Bead PeeningMethod No. 405C: 使用玻璃珠喷丸修复密封直径...

SECTION IV – REPAIR 3. 防护涂料及电镀的修复与应用-N.Method No. 403N: 铝的化学膜修补

3. Repair and Application of Protective Coatings and Plating 防护涂料及电镀的修复与应用N.Method No. 403N: Chemical Film Touch-Up of AluminumMethod No. 403N: 铝的化学膜修补(1) Remov...

SECTION IV – REPAIR 修理(三)-A.Method No. 403A: Anodized Aluminum and Aluminum-alloy Repair

3. Repair and Application of Protective Coatings and Plating 防护涂料及电镀的修复与应用A.Method No. 403A: Anodized Aluminum and Aluminum-alloy Repair方法403A:阳极氧化铝和铝合金修...

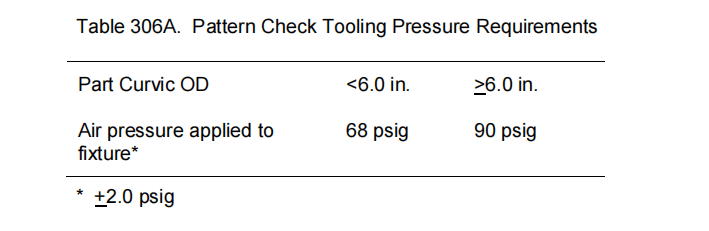

SECTION III – INSPECTION 1. Standard Inspection Practices -I.Curvic Coupling Inspection弧形联轴器检查

I.Curvic Coupling Inspection 弧形联轴器检查NOTE: Nomenclature for curvic coupling is provided in Figure 320.注:图 320 中提供了弧形联轴器的命名。(1) Inspect components with curvic ...

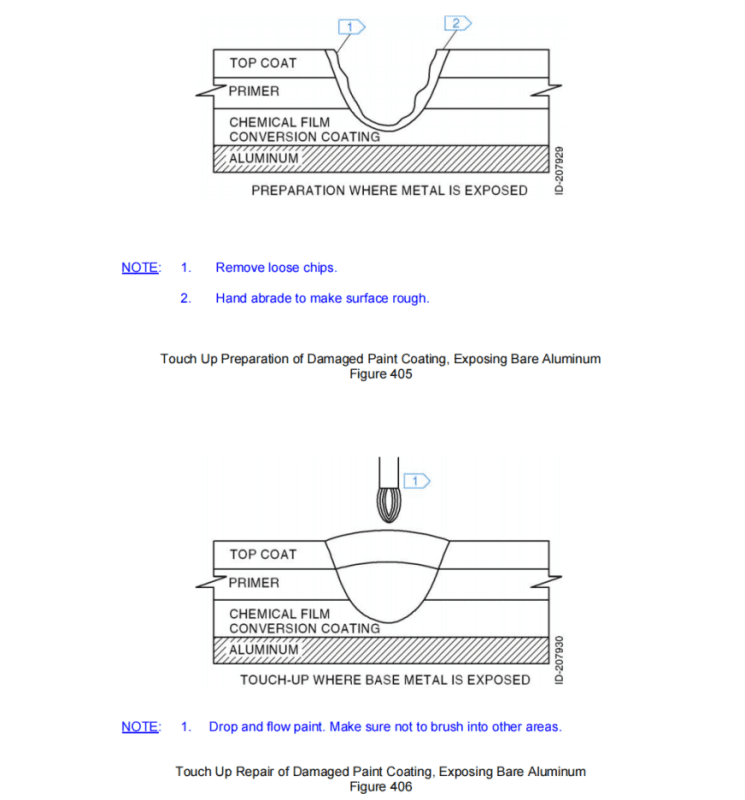

SECTION IV – REPAIR 修理(三)-M.Method No. 403M: Repair of Paint Coatings Damaged Through Primer and Paint Topcoat, Exposing Bare Aluminum – Epoxy-Amine Systems

3. Repair and Application of Protective Coatings and Plating 防护涂料及电镀的修复与应用M.Method No. 403M: Repair of Paint Coatings Damaged Through Primer and Paint Topcoat, Exposin...

SECTION IV – REPAIR 3. 防护涂料及电镀的修复与应用-D.Method No.403D:金属喷涂修复

3. Repair and Application of Protective Coatings and Plating 防护涂料及电镀的修复与应用D.Method No. 403D: Metal Spray RepairMethod No.403D:金属喷涂修复NOTE: Electric Arc Spray and...

SECTION III – INSPECTION 检查(四)-目视检查Visual Inspection

G. Visual Inspection 目视检查 (1) General Information 通用信息 (a) Visual inspection involves viewing the part for general appearance in an effort to locate conditions, which cause...

SECTION IV – REPAIR 6 -修理镁零件-A.Method No. 406A:轻微损坏修理

6.Repairing Magnesium Parts修理镁零件A.Method No. 406A: Minor Damage RepairMethod No. 406A:轻微损坏修理NOTE: Refer to Method No. 403L for repair of paint coatings for magnesium par...

SECTION IV – REPAIR 3. 防护涂料及电镀的修复与应用-O. Method No. 403O:镁的化学膜修补

3. Repair and Application of Protective Coatings and Plating 防护涂料及电镀的修复与应用O.Method No. 403O: Chemical Film Touch-Up of MagnesiumMethod No. 403O:镁的化学膜修补(1) Remov...

SECTION IV – REPAIR 修理(三)-B.Method No. 403B: Hard Chrome Plated Parts Repair

3. Repair and Application of Protective Coatings and Plating 防护涂料及电镀的修复与应用B.Method No. 403B: Hard Chrome Plated Parts Repair方法编号403B:硬铬镀件修复NOTE: Hard chrome...

SECTION III – INSPECTION 1. Standard Inspection Practices -K.过滤器气泡点检查

K.Bubble Point Check for Filters过滤器气泡点检查(1) Perform bubble point test on filter in accordance with MIL-F-5504B.根据MIL-F-5504B对过滤器进行气泡点测试。(a) The largest pore s...

SECTION IV – REPAIR 修理(三)-Method No. 403N: Chemical Film Touch-Up of Aluminum

3. Repair and Application of Protective Coatings and Plating 防护涂料及电镀的修复与应用N.Method No. 403N: Chemical Film Touch-Up of AluminumMethod No. 403N: 铝的化学膜修补(1) Remov...

SECTION IV – REPAIR 3. 防护涂料及电镀的修复与应用-E.Method No. 403E:干膜润滑剂修复

3. Repair and Application of Protective Coatings and Plating 防护涂料及电镀的修复与应用E.Method No. 403E: Dry-film Lubricant RepairMethod No. 403E:干膜润滑剂修复Dry-film lubricant...

SECTION III – INSPECTION 检查(五)-电气组件检查

H. Electrical Component Inspection 电气组件检查CAUTION: REFER TO APPLICABLE MANUAL PRIOR TO PERFORMING ANY ELECTRICAL CHECKS TO ENSURE THAT CHECKS WILL NOT DAMAGE EQUIPMENT.注意:...

HOEYWELL SECTION II – CLEANING 1. 标准清洁程序-通用

TABLE OF CONTENTS 目录SECTION 章节1. Standard Cleaning Practices标准清洁规范A. General通用2. Preparation of Cleaning Solutions清洁溶液的配制A. Method No. 202A: Alkaline Cleaning So...

SECTION IV – REPAIR 6 -修理镁零件-B.Method No. 406B:镁合金零件严重损坏修复

6.Repairing Magnesium Parts修理镁零件B.Method No. 406B: Magnesium-Alloy Parts Heavy Damage RepairMethod No. 406B:镁合金零件严重损坏修复Repair minor damage to magnesium-alloy parts ...