分类

子分类

排序

SECTION III – INSPECTION 检查(八)-压降检查:清洁的金属滤芯

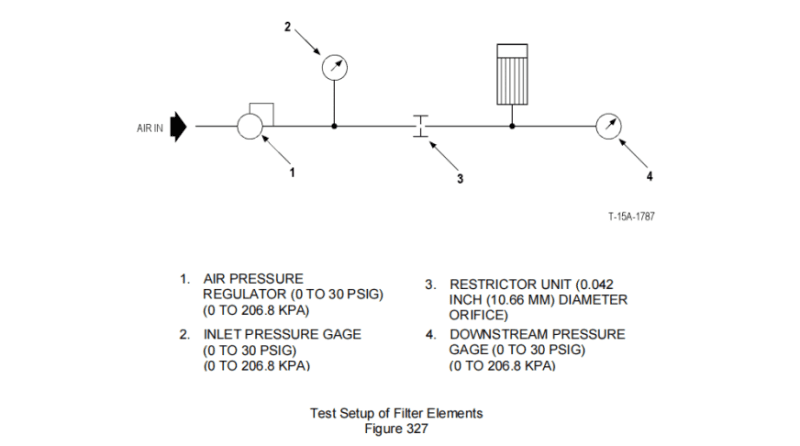

L.Pressure Drop Check: Cleaned Metallic Filter Elements压降检查:清洁的金属滤芯Check pressure drop of cleaned filter element as follows:检查清洁后的滤芯压降,方法如下:NOTE: Check ...

HOEYWELL SECTION II – CLEANING 清洁(四)

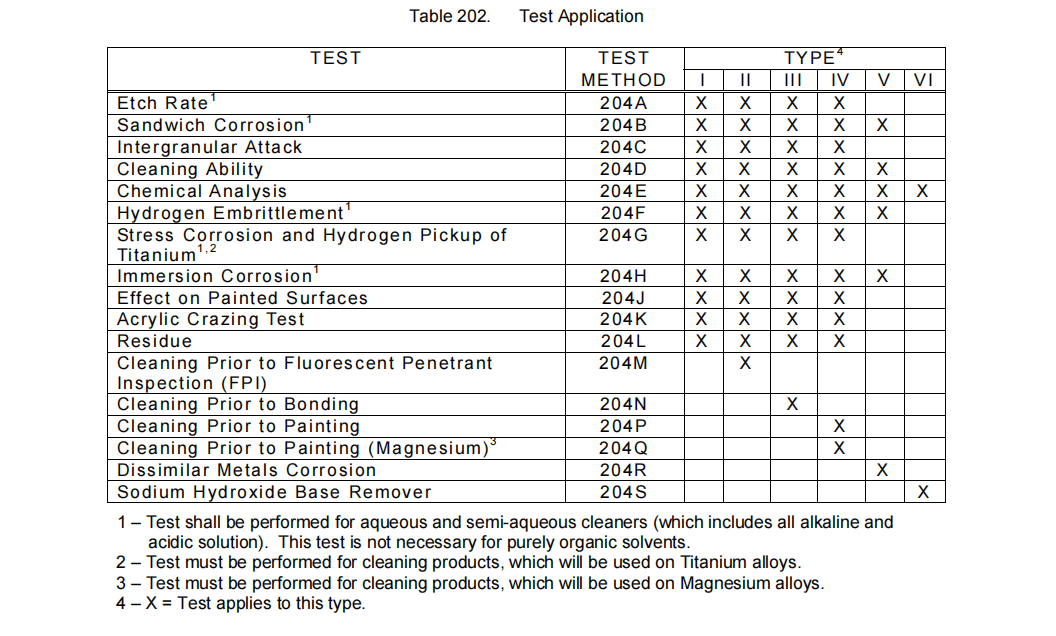

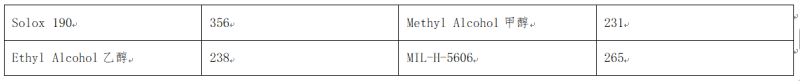

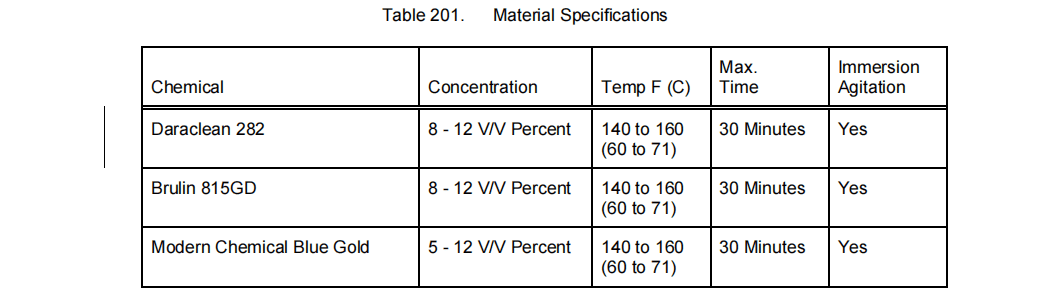

4. Alternate Cleaners 替代清洁剂 A. General 通用 (1) Alternate cleaners may be used in lieu of those specified in Method No. 202A and Method No. 202E. Previously approved alternate...

HOEYWELL SECTION I – DISASSEMBLY分解

SECTION I – DISASSEMBLY分解 TABLE OF CONTENTS 目录 SECTION 章节 1. Standard Disassembly Practices 标准分解操作 A. General 通用 B. Identification of Matched Parts and Sets 识别配合...

HOEYWELL SECTION II – CLEANING 清洁(一)

TABLE OF CONTENTS 目录 SECTION 章节 1. Standard Cleaning Practices 标准清洁规范 A. General 通用 2. Preparation of Cleaning Solutions 清洁溶液的配制 A. Method No. 202A: Alkaline Cle...

HOEYWELL SECTION II – CLEANING 清洁(二)

2. Preparation of Cleaning Solutions 清洁溶液的配制 WARNING: SOLUTIONS USED FOR CLEANING ARE HAZARDOUS. AVOID INHALING FUMES, DUST, OR MIST. AVOID CONTACT WITH SKIN. AFTER PREPARAT...

SECTION III – INSPECTION 检查(三)之齿轮和花键检查

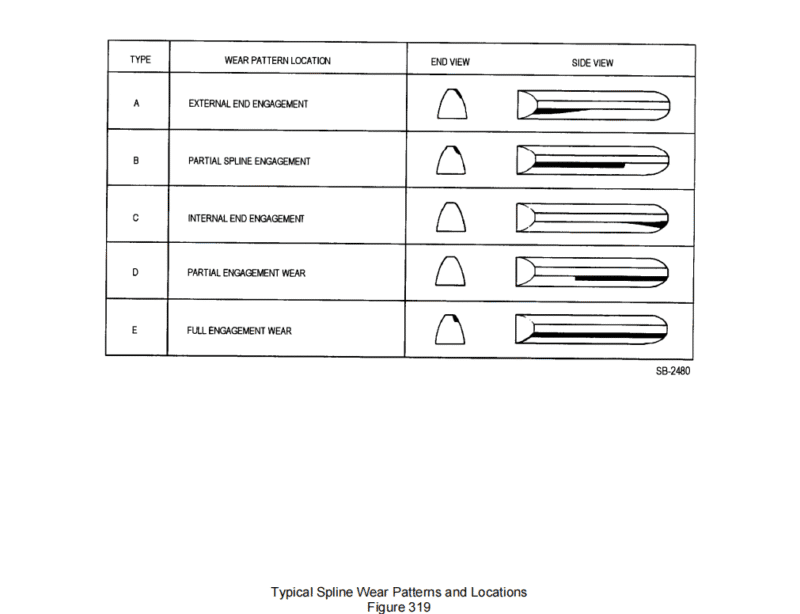

F. Gear and Spline Inspection 齿轮和花键检查 (1) Check gear and spline teeth as follows: 检查齿轮和花键齿,如下所示: (a) Perform visual check using a strong light and a minimum of...

SECTION III – INSPECTION 检查(六)-弧形联轴器检查

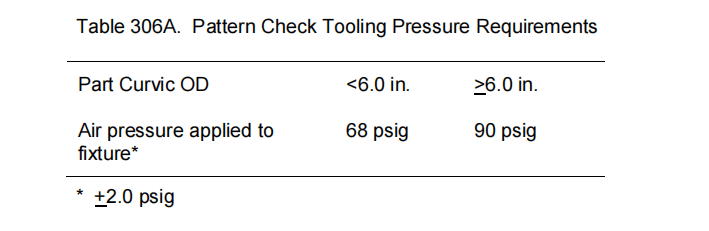

I.Curvic Coupling Inspection 弧形联轴器检查NOTE: Nomenclature for curvic coupling is provided in Figure 320.注:图 320 中提供了弧形联轴器的命名。(1) Inspect components with curvic ...

SECTION III – INSPECTION 检查(七)-过滤器气泡点检查

K.Bubble Point Check for Filters过滤器气泡点检查(1) Perform bubble point test on filter in accordance with MIL-F-5504B.根据MIL-F-5504B对过滤器进行气泡点测试。(a) The largest pore s...

HOEYWELL INTRODUCTION 介绍

INTRODUCTION介绍 1. General 通用 Information provided in this manual pertains to overhaul and repair processing for parts manufactured by Honeywell Inc., Phoenix, Arizona. 本手册提...

SECTION III – INSPECTION 检查(二)之轴承检查

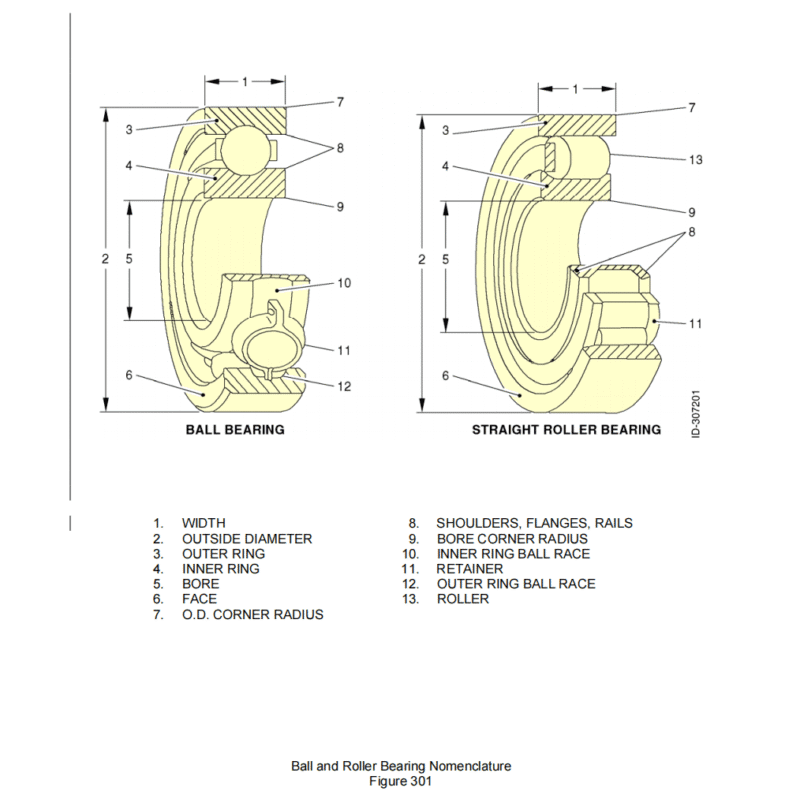

E. Bearing Inspection 轴承检查 (1) Separable Bearings: 可分解的轴承。 Table 301. Separable Bearing Defect Definitions 表301 可分解轴承缺陷的定义 Term 项目 Definition (Description o...

SECTION III – INSPECTION 检查(四)-目视检查Visual Inspection

G. Visual Inspection 目视检查 (1) General Information 通用信息 (a) Visual inspection involves viewing the part for general appearance in an effort to locate conditions, which cause...

SECTION III – INSPECTION 检查(五)-电气组件检查

H. Electrical Component Inspection 电气组件检查CAUTION: REFER TO APPLICABLE MANUAL PRIOR TO PERFORMING ANY ELECTRICAL CHECKS TO ENSURE THAT CHECKS WILL NOT DAMAGE EQUIPMENT.注意:...

SECTION IV – REPAIR 6 -修理镁零件-A.Method No. 406A:轻微损坏修理

6.Repairing Magnesium Parts修理镁零件A.Method No. 406A: Minor Damage RepairMethod No. 406A:轻微损坏修理NOTE: Refer to Method No. 403L for repair of paint coatings for magnesium par...

SECTION IV – REPAIR 修理(三)-O. Method No. 403O: Chemical Film Touch-Up of Magnesium

3. Repair and Application of Protective Coatings and Plating 防护涂料及电镀的修复与应用O.Method No. 403O: Chemical Film Touch-Up of MagnesiumMethod No. 403O:镁的化学膜修补(1) Remov...

SECTION III – INSPECTION 检查(一)

SECTION III – INSPECTION第三章 – 检查 TABLE OF CONTENTS 目录 SECTION 章节 1. Standard Inspection Practices 标准检查施工 A. General 通用 B. General Inspection Procedures 通用检查...

SECTION IV – REPAIR 修理(三)-Method No. 403N: Chemical Film Touch-Up of Aluminum

3. Repair and Application of Protective Coatings and Plating 防护涂料及电镀的修复与应用N.Method No. 403N: Chemical Film Touch-Up of AluminumMethod No. 403N: 铝的化学膜修补(1) Remov...

SECTION IV – REPAIR 3. 防护涂料及电镀的修复与应用-O. Method No. 403O:镁的化学膜修补

3. Repair and Application of Protective Coatings and Plating 防护涂料及电镀的修复与应用O.Method No. 403O: Chemical Film Touch-Up of MagnesiumMethod No. 403O:镁的化学膜修补(1) Remov...

HOEYWELL SECTION II – CLEANING 清洁(三)

3. Standard Cleaning Methods 标准清洁方法 CAUTION: SPECIFIED CLEANING METHODS OUTLINED MUST BE FOLLOWED. THE VARIOUS SOLUTIONS AND MATERIALS SPECIFIED IN THE CLEANING METHODS CAN B...

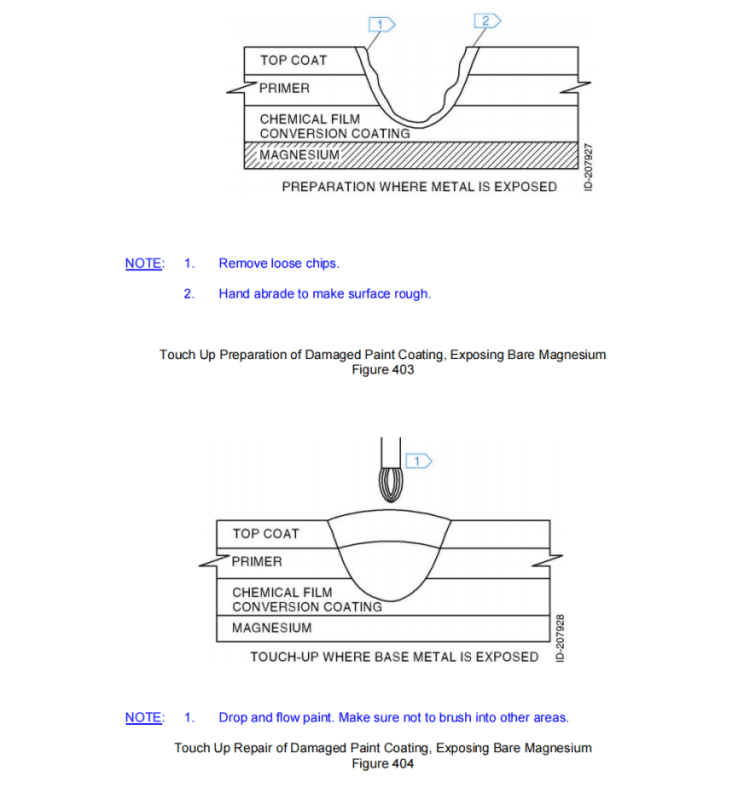

SECTION IV – REPAIR 修理(三)-L.Method No. 403L: Repair of Paint Coatings Damaged Through Primer and Paint Topcoat, Exposing Bare Magnesium – Epoxy-Amine Systems

3. Repair and Application of Protective Coatings and Plating 防护涂料及电镀的修复与应用L.Method No. 403L: Repair of Paint Coatings Damaged Through Primer and Paint Topcoat, Exposin...

SECTION IV – REPAIR 6 -修理镁零件-B.Method No. 406B:镁合金零件严重损坏修复

6.Repairing Magnesium Parts修理镁零件B.Method No. 406B: Magnesium-Alloy Parts Heavy Damage RepairMethod No. 406B:镁合金零件严重损坏修复Repair minor damage to magnesium-alloy parts ...

SECTION IV – REPAIR 6 -修理镁零件-C.Method No. 406C:镁合金零件的沟槽和划伤修复

6.Repairing Magnesium Parts修理镁零件C.Method No. 406C: Magnesium-Alloy Parts Gouge and Scoring RepairMethod No. 406C:镁合金零件的沟槽和划伤修复Repair minor damage to magnesium-all...

SECTION IV – REPAIR 3.防护涂料及电镀的修复与应用-J.Method No. 403J: 选择性电镀

3. Repair and Application of Protective Coatings and Plating 防护涂料及电镀的修复与应用J.Method No. 403J: Selective ElectroplatingMethod No. 403J:选择性电镀NOTE: If parts out of ap...