分类

子分类

排序

SECTION IV – REPAIR 3. 防护涂料及电镀的修复与应用-G.Method No. 403G:耐磨涂层表面磨损修复

3. Repair and Application of Protective Coatings and Plating 防护涂料及电镀的修复与应用G.Method No. 403G: Abradable Coating Surface Wear RepairMethod No. 403G:耐磨涂层表面磨损修复N...

SECTION IV – REPAIR 3. 防护涂料及电镀的修复与应用-H.Method No. 403H:镀银修复

3. Repair and Application of Protective Coatings and Plating 防护涂料及电镀的修复与应用H.Method No. 403H: Silver Plating RepairMethod No. 403H:镀银修复NOTE: If the type of silver p...

SECTION IV – REPAIR 1.标准修理程序-概述

1.Standard Repair Practices标准修理程序A.General概述The methods and procedures presented are recommended by the manufacturer to facilitate overhaul and repair of a unit. The inform...

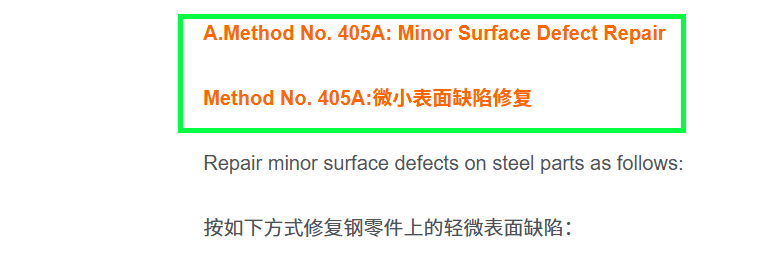

SECTION IV – REPAIR 5.清除钢制零件上的损伤-A.Method No. 405A:微小表面缺陷修复

5.Removing Damage from Steel Parts清除钢制零件上的损伤A.Method No. 405A: Minor Surface Defect RepairMethod No. 405A:微小表面缺陷修复Repair minor surface defects on steel parts as f...

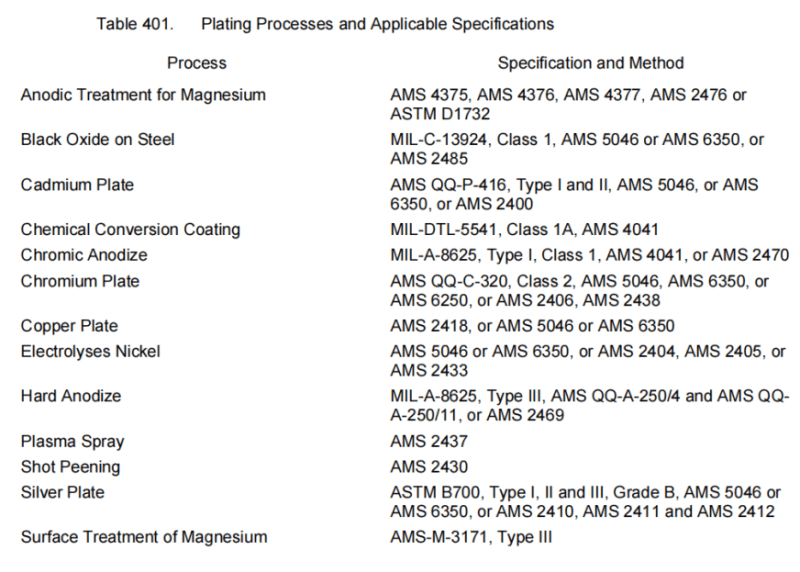

SECTION IV – REPAIR 修理(三)-A.Method No. 403A: Anodized Aluminum and Aluminum-alloy Repair

3. Repair and Application of Protective Coatings and Plating 防护涂料及电镀的修复与应用A.Method No. 403A: Anodized Aluminum and Aluminum-alloy Repair方法403A:阳极氧化铝和铝合金修...

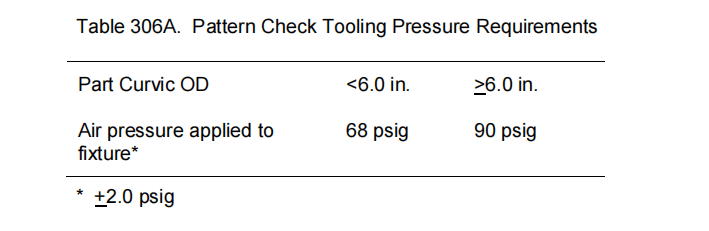

SECTION III – INSPECTION 1. Standard Inspection Practices -I.Curvic Coupling Inspection弧形联轴器检查

I.Curvic Coupling Inspection 弧形联轴器检查NOTE: Nomenclature for curvic coupling is provided in Figure 320.注:图 320 中提供了弧形联轴器的命名。(1) Inspect components with curvic ...

SECTION IV – REPAIR 3. 防护涂料及电镀的修复与应用-D.Method No.403D:金属喷涂修复

3. Repair and Application of Protective Coatings and Plating 防护涂料及电镀的修复与应用D.Method No. 403D: Metal Spray RepairMethod No.403D:金属喷涂修复NOTE: Electric Arc Spray and...

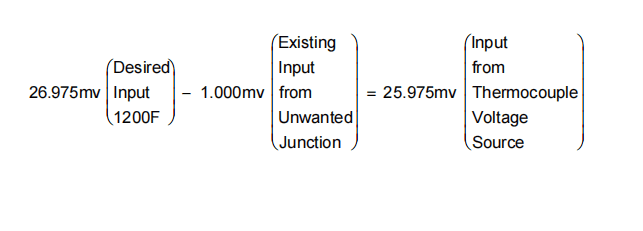

SECTION III – INSPECTION 1. Standard Inspection Practices -M.用于电子设备校准和检查的热电偶模拟器

M.Thermocouple Simulators for Calibration and Checkout of Electronic Equipment 用于电子设备校准和检查的热电偶模拟器(1) For test purposes in simulating a thermocouple, a common and ...

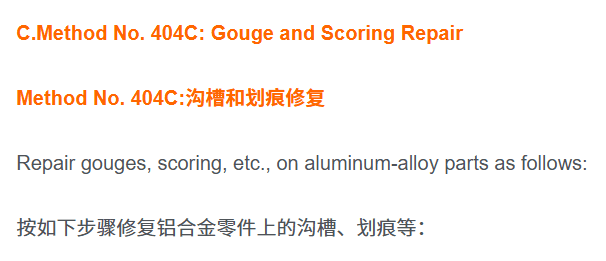

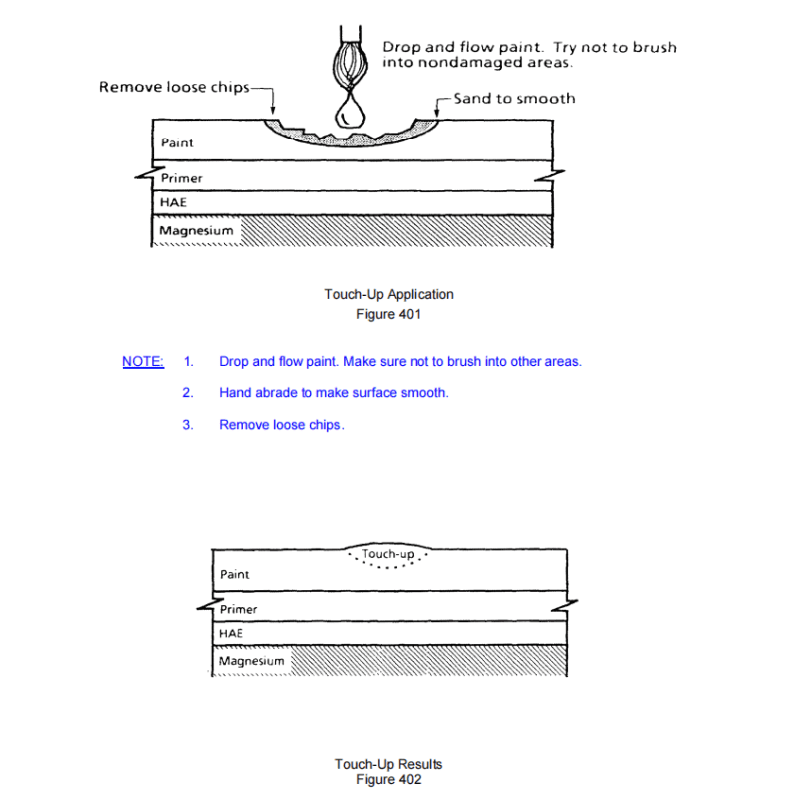

SECTION IV – REPAIR 4. 修理铝制零件-C.Method No. 404C:沟槽和划痕修复

4. Repairing Aluminum Parts 修理铝制零件C.Method No. 404C: Gouge and Scoring RepairMethod No. 404C:沟槽和划痕修复Repair gouges, scoring, etc., on aluminum-alloy parts as follows:按...

SECTION III – INSPECTION 检查 1. Standard Inspection Practices 标准检查施工

SECTION III – INSPECTION第三章 – 检查TABLE OF CONTENTS目录SECTION章节1. Standard Inspection Practices标准检查施工A. General通用B. General Inspection Procedures通用检查程序C. Magn...

SECTION IV – REPAIR 修理(三)-H.Method No. 403H: Silver Plating Repair

3. Repair and Application of Protective Coatings and Plating 防护涂料及电镀的修复与应用H.Method No. 403H: Silver Plating RepairMethod No. 403H:镀银修复NOTE: If the type of silver p...

SECTION IV – REPAIR 3. 防护涂料及电镀的修复与应用-K.Method No. 403K:修复受损的油漆涂层-环氧胺体系

3. Repair and Application of Protective Coatings and Plating 防护涂料及电镀的修复与应用K.Method No. 403K: Repair of Damaged Paint Coatings - Epoxy-Amine SystemsMethod No. 403K:修复...

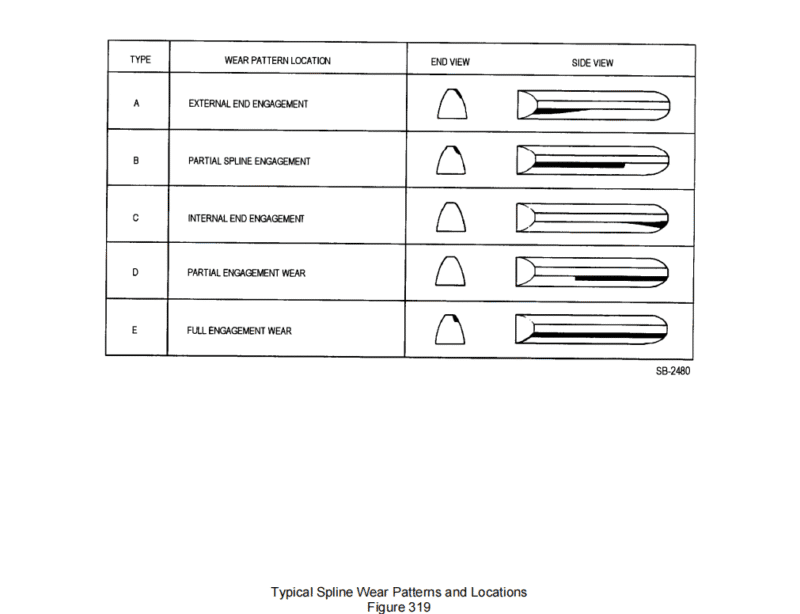

SECTION III – INSPECTION 1. Standard Inspection Practices -F. 齿轮和花键检查

F. Gear and Spline Inspection 齿轮和花键检查(1) Check gear and spline teeth as follows:检查齿轮和花键齿,如下所示:(a) Perform visual check using a strong light and a minimum of 5 ...

SECTION IV – REPAIR 修理(三)-I.Method No. 403I: Electroless Nickel Plating

3. Repair and Application of Protective Coatings and Plating 防护涂料及电镀的修复与应用I.Method No. 403I: Electroless Nickel PlatingMethod No. 403I:化学镀镍CAUTION: BECAUSE OF MASK...

SECTION IV – REPAIR 3. 防护涂料及电镀的修复与应用-C.Method No.403C:薄而致密的镀铬零件修复

3. Repair and Application of Protective Coatings and Plating 防护涂料及电镀的修复与应用C.Method No. 403C: Thin Dense Chrome Plated Parts RepairMethod No.403C:薄而致密的镀铬零件修...

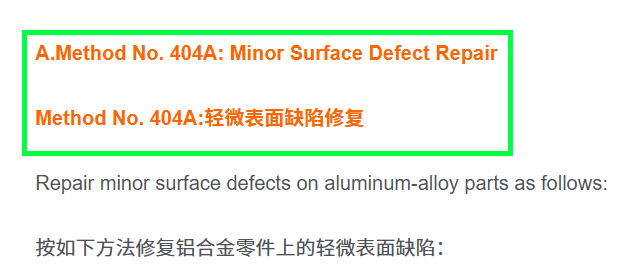

SECTION IV – REPAIR 4.修理铝制零件-A.Method No. 404A:轻微表面缺陷修复

4.Repairing Aluminum Parts修理铝制零件A.Method No. 404A: Minor Surface Defect RepairMethod No. 404A:轻微表面缺陷修复Repair minor surface defects on aluminum-alloy parts as follows:...

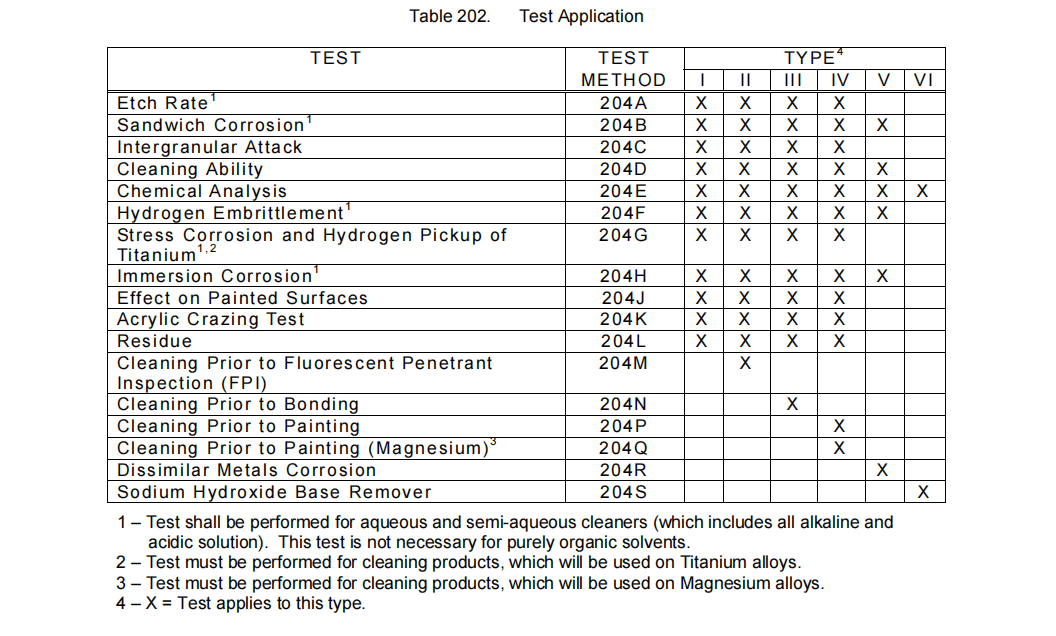

HOEYWELL SECTION II – CLEANING 3. Standard Cleaning Methods 标准清洁方法

3. Standard Cleaning Methods 标准清洁方法 CAUTION: SPECIFIED CLEANING METHODS OUTLINED MUST BE FOLLOWED. THE VARIOUS SOLUTIONS AND MATERIALS SPECIFIED IN THE CLEANING METHODS CAN B...

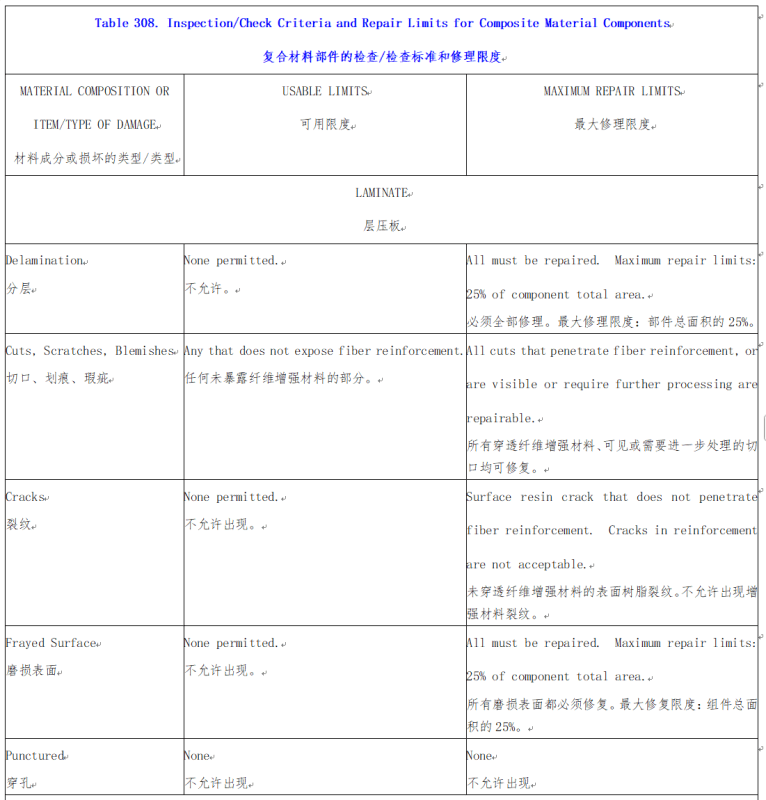

SECTION III – INSPECTION 1. Standard Inspection Practices -N.复合材料部件

N.Composite Material Components复合材料部件(1) Check per Table 308.按照表308进行检查。

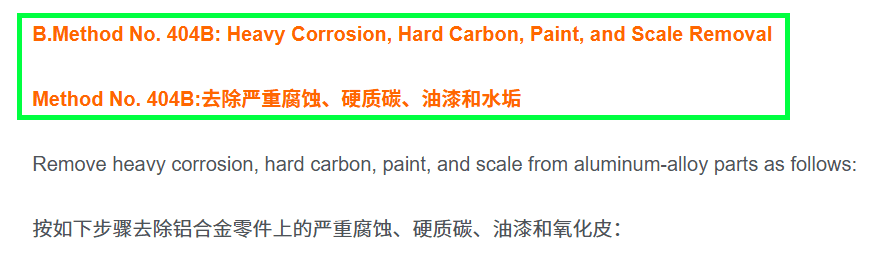

SECTION IV – REPAIR 4. 修理铝制零件-B.Method No. 404B: 去除严重腐蚀、硬质碳、油漆和水垢

4. Repairing Aluminum Parts 修理铝制零件B.Method No. 404B: Heavy Corrosion, Hard Carbon, Paint, and Scale RemovalMethod No. 404B:去除严重腐蚀、硬质碳、油漆和水垢Remove heavy corros...

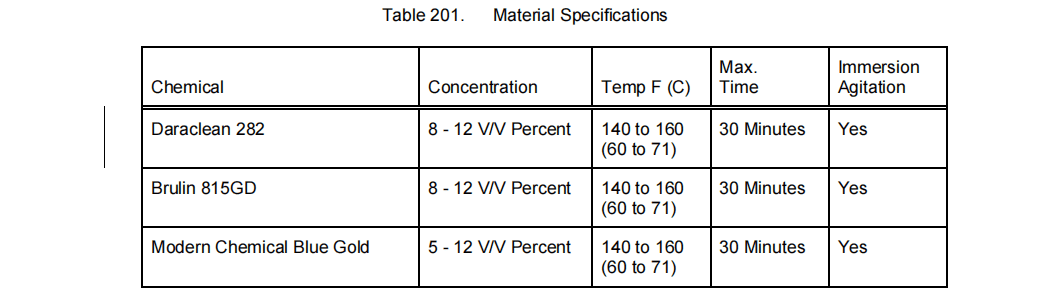

HOEYWELL SECTION II – CLEANING 4. 替代清洁剂

4. Alternate Cleaners 替代清洁剂A. General通用(1) Alternate cleaners may be used in lieu of those specified in Method No. 202A and Method No. 202E. Previously approved alternates a...

SECTION IV – REPAIR 3. 防护涂料及电镀的修复与应用-I.Method No. 403I:化学镀镍

3. Repair and Application of Protective Coatings and Plating 防护涂料及电镀的修复与应用I.Method No. 403I: Electroless Nickel PlatingMethod No. 403I:化学镀镍CAUTION: BECAUSE OF MASK...

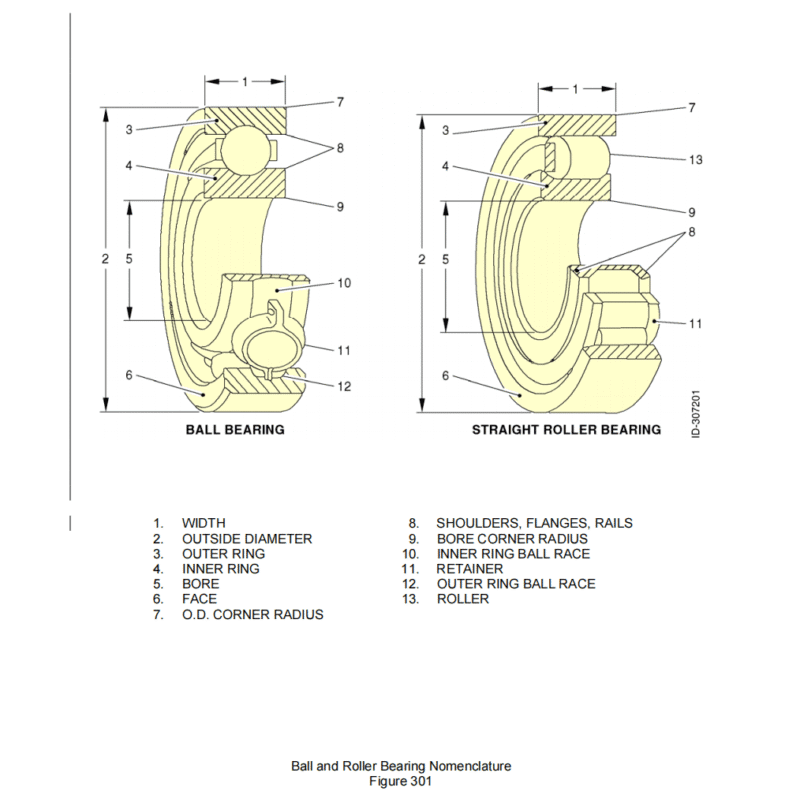

SECTION III – INSPECTION 1. Standard Inspection Practices -E. Bearing Inspection轴承检查

E. Bearing Inspection轴承检查(1) Separable Bearings:可分解的轴承。Table 301. Separable Bearing Defect Definitions表301 可分解轴承缺陷的定义Term项目Definition (Description of Defect...