分类

子分类

排序

SECTION IV – REPAIR 修理(三)-C.Method No. 403C: Thin Dense Chrome Plated Parts Repair

3. Repair and Application of Protective Coatings and Plating 防护涂料及电镀的修复与应用C.Method No. 403C: Thin Dense Chrome Plated Parts RepairMethod No.403C:薄而致密的镀铬零件修...

SECTION III – INSPECTION 1. Standard Inspection Practices -L.压降检查:清洁的金属滤芯

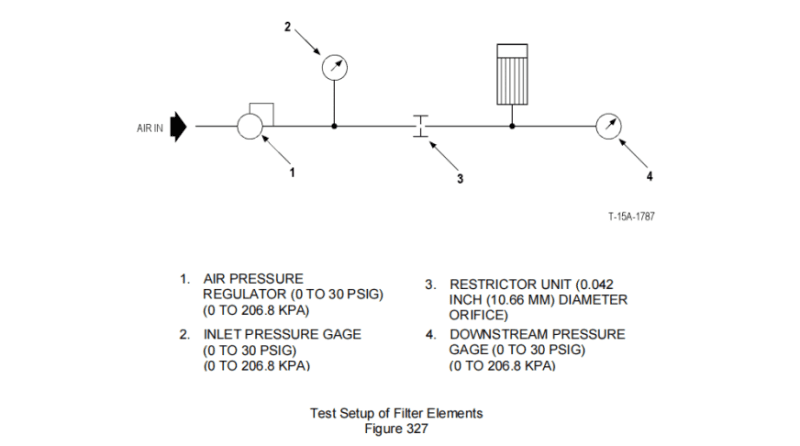

L.Pressure Drop Check: Cleaned Metallic Filter Elements压降检查:清洁的金属滤芯Check pressure drop of cleaned filter element as follows:检查清洁后的滤芯压降,方法如下:NOTE: Check ...

HOEYWELL INTRODUCTION 介绍

INTRODUCTION介绍 1. General 通用 Information provided in this manual pertains to overhaul and repair processing for parts manufactured by Honeywell Inc., Phoenix, Arizona. 本手册提...

SECTION IV – REPAIR 修理(三)-O. Method No. 403O: Chemical Film Touch-Up of Magnesium

3. Repair and Application of Protective Coatings and Plating 防护涂料及电镀的修复与应用O.Method No. 403O: Chemical Film Touch-Up of MagnesiumMethod No. 403O:镁的化学膜修补(1) Remov...

SECTION IV – REPAIR 3. 防护涂料及电镀的修复与应用-F.Method No. 403F:等离子喷涂修复

3. Repair and Application of Protective Coatings and Plating 防护涂料及电镀的修复与应用F.Method No. 403F: Plasma Spray RepairMethod No. 403F:等离子喷涂修复NOTE: Electric Arc Metal...

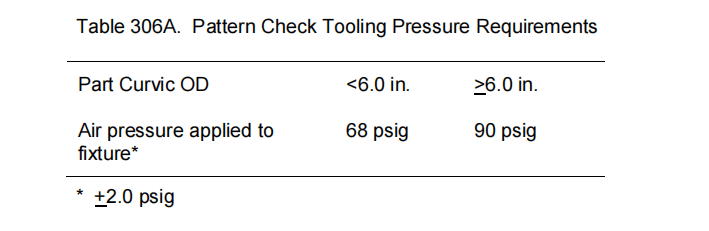

SECTION III – INSPECTION 检查(六)-弧形联轴器检查

I.Curvic Coupling Inspection 弧形联轴器检查NOTE: Nomenclature for curvic coupling is provided in Figure 320.注:图 320 中提供了弧形联轴器的命名。(1) Inspect components with curvic ...

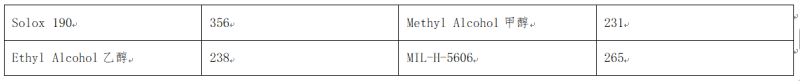

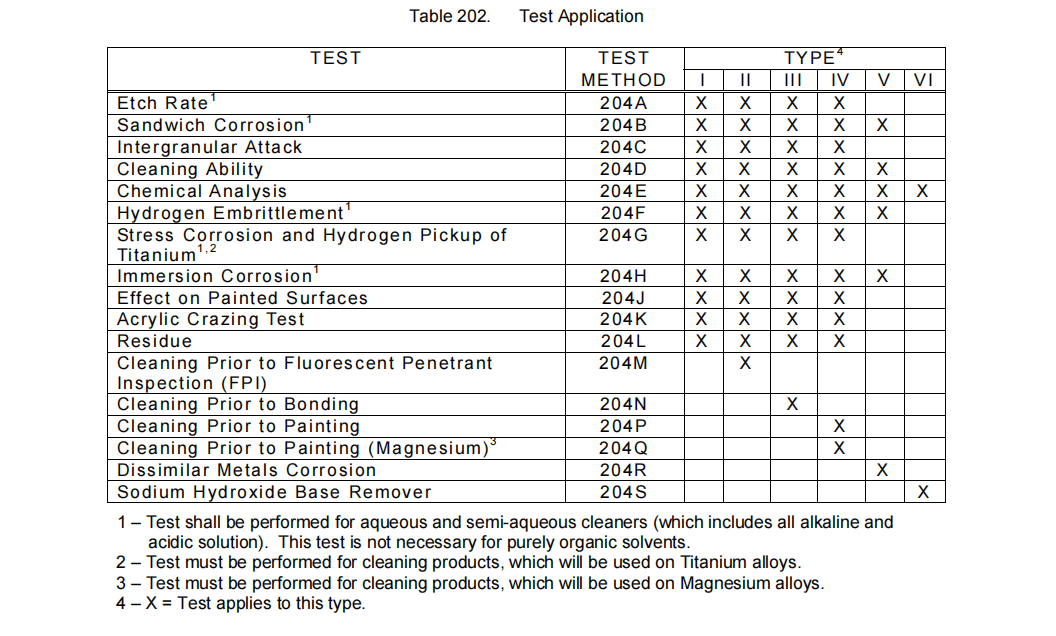

HOEYWELL SECTION II – CLEANING 2. 清洁溶液的配制

2. Preparation of Cleaning Solutions 清洁溶液的配制WARNING: SOLUTIONS USED FOR CLEANING ARE HAZARDOUS. AVOID INHALING FUMES, DUST, OR MIST. AVOID CONTACT WITH SKIN. AFTER PREPARATI...

SECTION IV – REPAIR 6 -修理镁零件-C.Method No. 406C:镁合金零件的沟槽和划伤修复

6.Repairing Magnesium Parts修理镁零件C.Method No. 406C: Magnesium-Alloy Parts Gouge and Scoring RepairMethod No. 406C:镁合金零件的沟槽和划伤修复Repair minor damage to magnesium-all...

SECTION IV – REPAIR 修理(三)-D.Method No. 403D: Metal Spray Repair

3. Repair and Application of Protective Coatings and Plating 防护涂料及电镀的修复与应用D.Method No. 403D: Metal Spray RepairMethod No.403D:金属喷涂修复NOTE: Electric Arc Spray and...

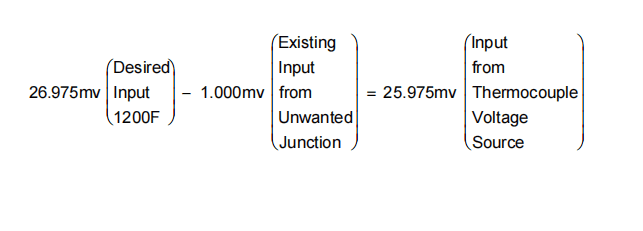

SECTION III – INSPECTION 1. Standard Inspection Practices -M.用于电子设备校准和检查的热电偶模拟器

M.Thermocouple Simulators for Calibration and Checkout of Electronic Equipment 用于电子设备校准和检查的热电偶模拟器(1) For test purposes in simulating a thermocouple, a common and ...

HOEYWELL SECTION I – DISASSEMBLY分解

SECTION I – DISASSEMBLY分解 TABLE OF CONTENTS 目录 SECTION 章节 1. Standard Disassembly Practices 标准分解操作 A. General 通用 B. Identification of Matched Parts and Sets 识别配合...

SECTION IV – REPAIR 4.修理铝制零件-A.Method No. 404A:轻微表面缺陷修复

4.Repairing Aluminum Parts修理铝制零件A.Method No. 404A: Minor Surface Defect RepairMethod No. 404A:轻微表面缺陷修复Repair minor surface defects on aluminum-alloy parts as follows:...

SECTION IV – REPAIR 3. 防护涂料及电镀的修复与应用-G.Method No. 403G:耐磨涂层表面磨损修复

3. Repair and Application of Protective Coatings and Plating 防护涂料及电镀的修复与应用G.Method No. 403G: Abradable Coating Surface Wear RepairMethod No. 403G:耐磨涂层表面磨损修复N...

SECTION III – INSPECTION 检查(七)-过滤器气泡点检查

K.Bubble Point Check for Filters过滤器气泡点检查(1) Perform bubble point test on filter in accordance with MIL-F-5504B.根据MIL-F-5504B对过滤器进行气泡点测试。(a) The largest pore s...

HOEYWELL SECTION II – CLEANING 3. Standard Cleaning Methods 标准清洁方法

3. Standard Cleaning Methods 标准清洁方法 CAUTION: SPECIFIED CLEANING METHODS OUTLINED MUST BE FOLLOWED. THE VARIOUS SOLUTIONS AND MATERIALS SPECIFIED IN THE CLEANING METHODS CAN B...

SECTION IV – REPAIR 修理(三)-E.Method No. 403E: Dry-film Lubricant Repair

3. Repair and Application of Protective Coatings and Plating 防护涂料及电镀的修复与应用E.Method No. 403E: Dry-film Lubricant RepairMethod No. 403E:干膜润滑剂修复Dry-film lubricant...

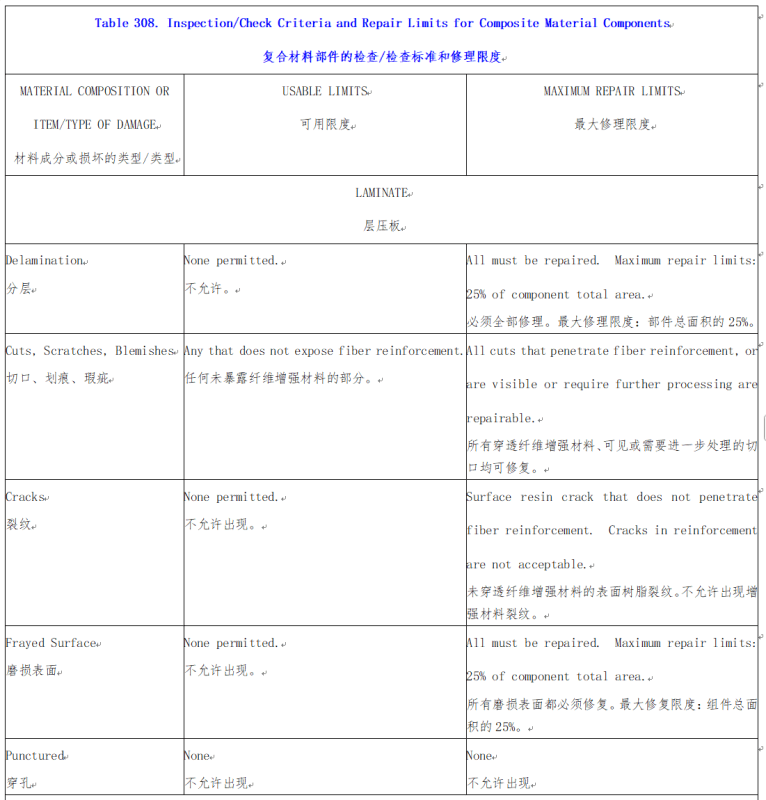

SECTION III – INSPECTION 1. Standard Inspection Practices -N.复合材料部件

N.Composite Material Components复合材料部件(1) Check per Table 308.按照表308进行检查。

HOEYWELL SECTION II – CLEANING 清洁(一)

TABLE OF CONTENTS 目录 SECTION 章节 1. Standard Cleaning Practices 标准清洁规范 A. General 通用 2. Preparation of Cleaning Solutions 清洁溶液的配制 A. Method No. 202A: Alkaline Cle...

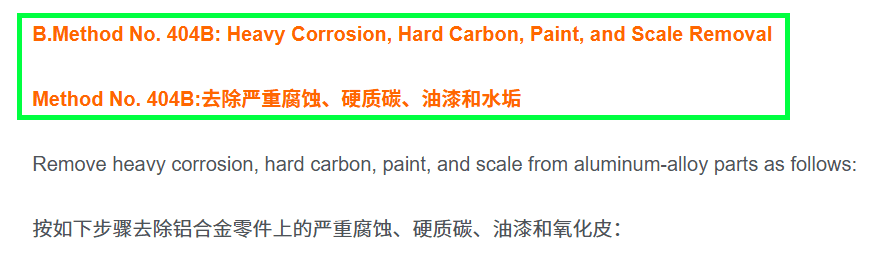

SECTION IV – REPAIR 4. 修理铝制零件-B.Method No. 404B: 去除严重腐蚀、硬质碳、油漆和水垢

4. Repairing Aluminum Parts 修理铝制零件B.Method No. 404B: Heavy Corrosion, Hard Carbon, Paint, and Scale RemovalMethod No. 404B:去除严重腐蚀、硬质碳、油漆和水垢Remove heavy corros...

SECTION IV – REPAIR 3. 防护涂料及电镀的修复与应用-H.Method No. 403H:镀银修复

3. Repair and Application of Protective Coatings and Plating 防护涂料及电镀的修复与应用H.Method No. 403H: Silver Plating RepairMethod No. 403H:镀银修复NOTE: If the type of silver p...

SECTION III – INSPECTION 检查(八)-压降检查:清洁的金属滤芯

L.Pressure Drop Check: Cleaned Metallic Filter Elements压降检查:清洁的金属滤芯Check pressure drop of cleaned filter element as follows:检查清洁后的滤芯压降,方法如下:NOTE: Check ...

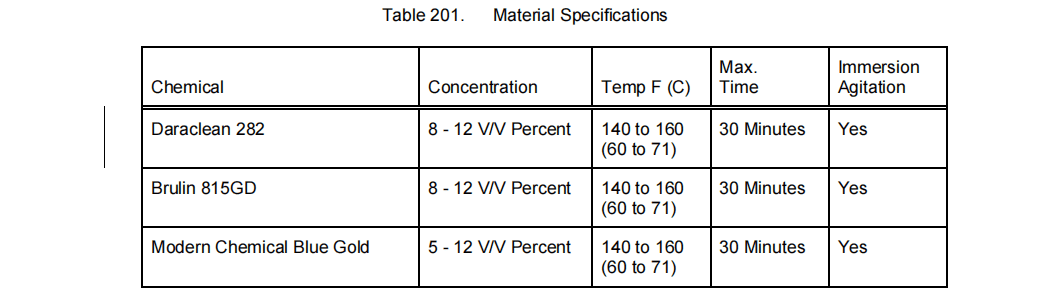

HOEYWELL SECTION II – CLEANING 4. 替代清洁剂

4. Alternate Cleaners 替代清洁剂A. General通用(1) Alternate cleaners may be used in lieu of those specified in Method No. 202A and Method No. 202E. Previously approved alternates a...