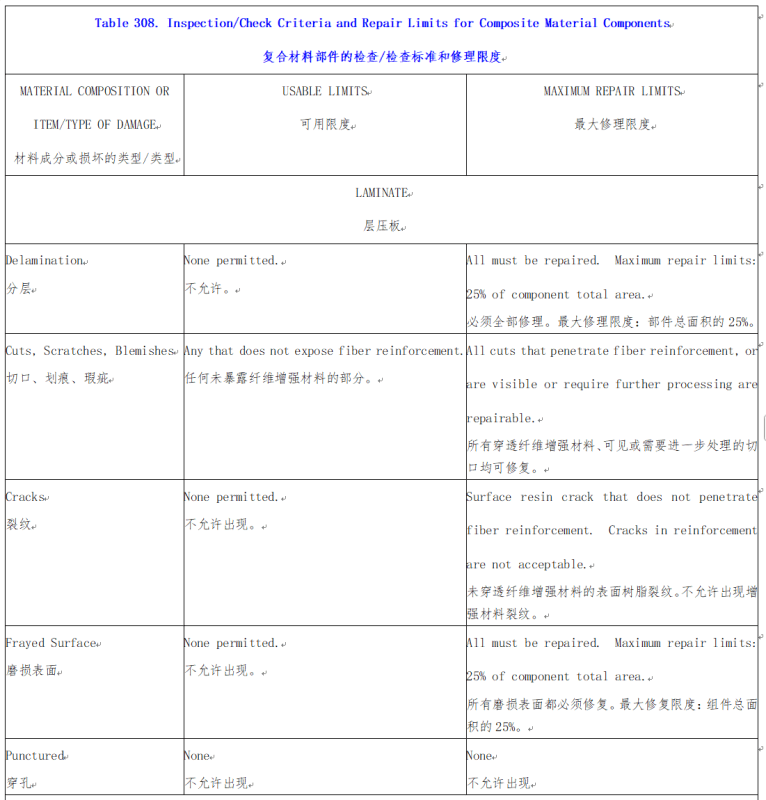

SECTION III – INSPECTION 1. Standard Inspection Practices -N.复合材料部件

N.Composite Material Components复合材料部件(1) Check per Table 308.按照表308进行检查。

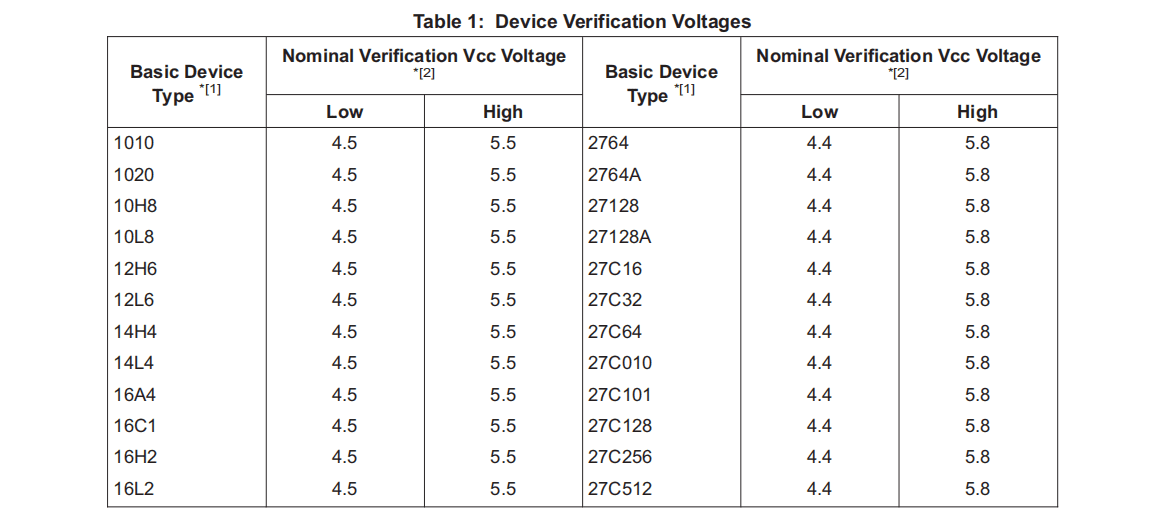

SOPM20-11-08如何编程可编程电路设备

如何编程可编程电路设备HOW TO PROGRAM PROGRAMMABLE CIRCUIT DEVICES 1. INTRODUCTION 介绍 A. The data in this subject gives general procedures to put programs into Boeing-supplied pro...

SECTION IV – REPAIR 13-电气元件修理

13.Repairing Electrical Components 电气元件修理 NOTE: The following methods are typical only. Refer to applicable manual for unit in work for specific instructions. 注:以下方法仅...

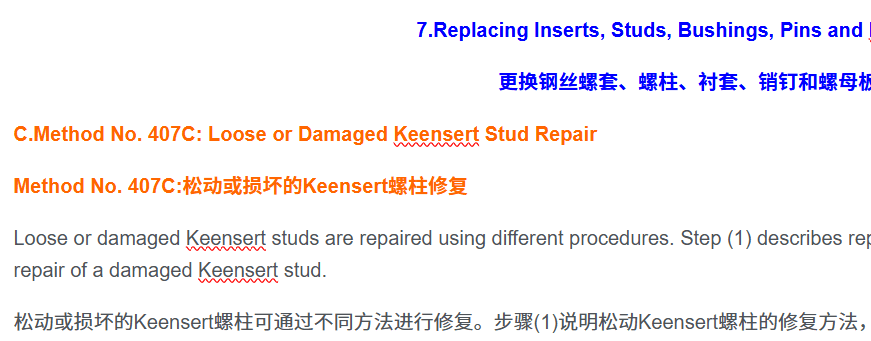

SECTION IV – REPAIR 7-更换钢丝螺套、螺柱、衬套、销钉和螺母板-C.Method No. 407C:松动或损坏的Keensert螺柱修复

7.Replacing Inserts, Studs, Bushings, Pins and Nutplates更换钢丝螺套、螺柱、衬套、销钉和螺母板C.Method No. 407C: Loose or Damaged Keensert Stud RepairMethod No. 407C:松动或损坏的Ke...

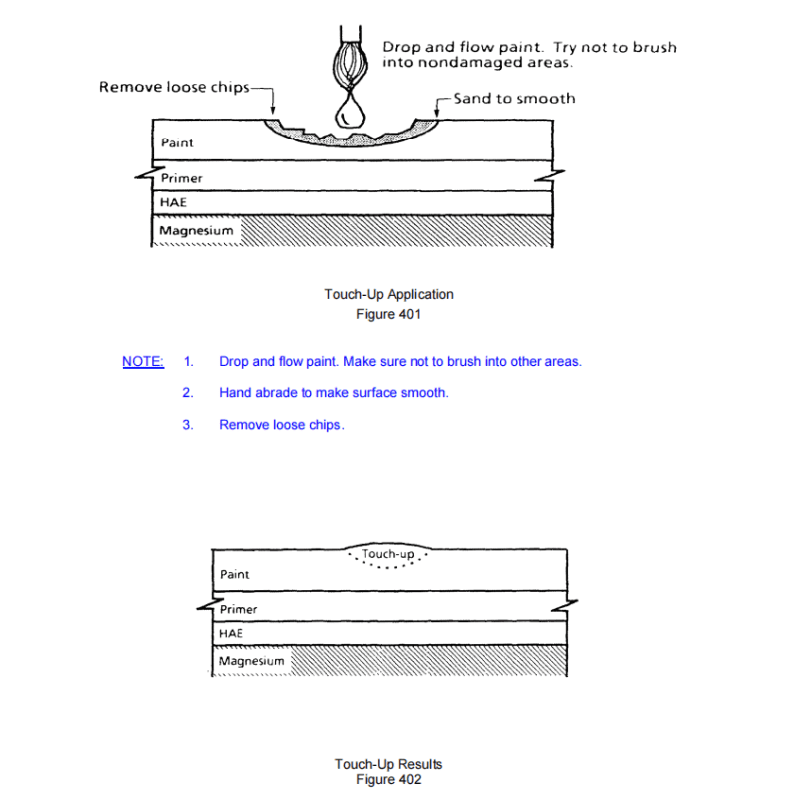

SECTION IV – REPAIR 3. 防护涂料及电镀的修复与应用-K.Method No. 403K:修复受损的油漆涂层-环氧胺体系

3. Repair and Application of Protective Coatings and Plating 防护涂料及电镀的修复与应用K.Method No. 403K: Repair of Damaged Paint Coatings - Epoxy-Amine SystemsMethod No. 403K:修复...

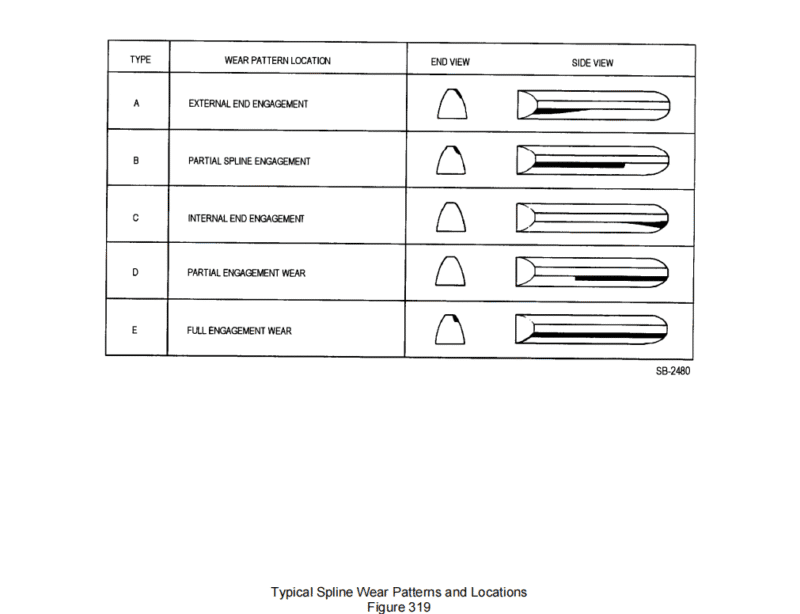

SECTION III – INSPECTION 1. Standard Inspection Practices -F. 齿轮和花键检查

F. Gear and Spline Inspection 齿轮和花键检查(1) Check gear and spline teeth as follows:检查齿轮和花键齿,如下所示:(a) Perform visual check using a strong light and a minimum of 5 ...

SECTION IV – REPAIR 3. 防护涂料及电镀的修复与应用-C.Method No.403C:薄而致密的镀铬零件修复

3. Repair and Application of Protective Coatings and Plating 防护涂料及电镀的修复与应用C.Method No. 403C: Thin Dense Chrome Plated Parts RepairMethod No.403C:薄而致密的镀铬零件修...

SECTION IV – REPAIR 3. 防护涂料及电镀的修复与应用-D.Method No.403D:金属喷涂修复

3. Repair and Application of Protective Coatings and Plating 防护涂料及电镀的修复与应用D.Method No. 403D: Metal Spray RepairMethod No.403D:金属喷涂修复NOTE: Electric Arc Spray and...

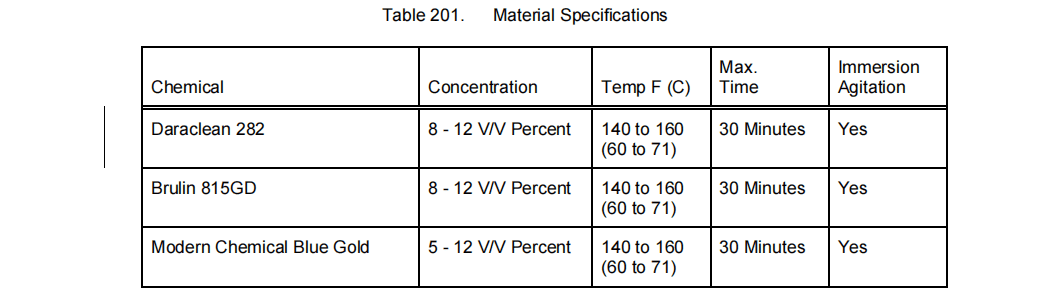

HOEYWELL SECTION II – CLEANING 2. 清洁溶液的配制

2. Preparation of Cleaning Solutions 清洁溶液的配制WARNING: SOLUTIONS USED FOR CLEANING ARE HAZARDOUS. AVOID INHALING FUMES, DUST, OR MIST. AVOID CONTACT WITH SKIN. AFTER PREPARATI...

HOEYWELL SECTION II – CLEANING 3. Standard Cleaning Methods 标准清洁方法

3. Standard Cleaning Methods 标准清洁方法 CAUTION: SPECIFIED CLEANING METHODS OUTLINED MUST BE FOLLOWED. THE VARIOUS SOLUTIONS AND MATERIALS SPECIFIED IN THE CLEANING METHODS CAN B...

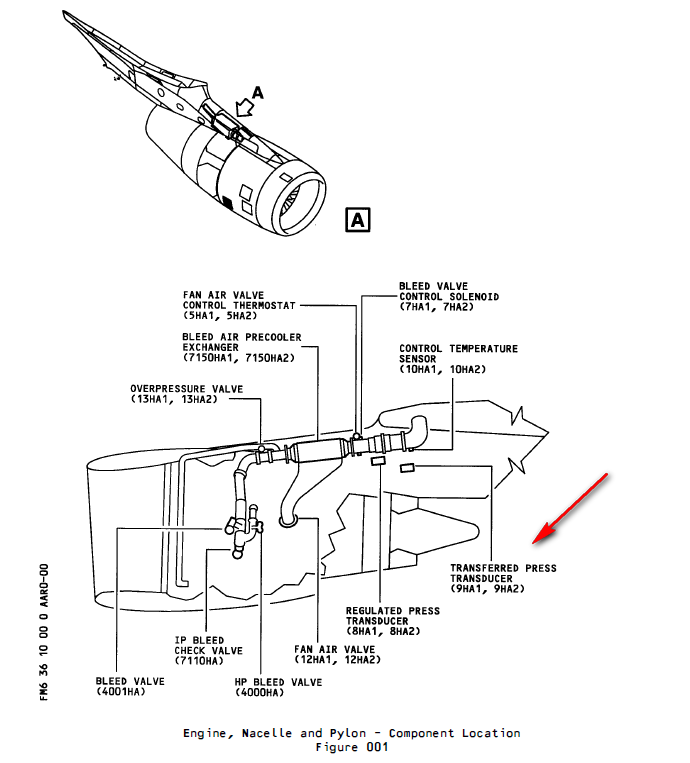

ZRA380-00 PRESSURE TRANSDUCER

一、名称PRESSURE TRANSDUCER压力传感器二、件号ZRA1990030,ZRA380-00,ZRA691-00三、章节号36-11-08四、适用机型A319/320/321/330/340五、系统36-PNEUMATIC气动六、安装位置发动机吊架七、部件...

SECTION IV – REPAIR 4. 修理铝制零件-D.Method No. 404D:燃油和滑油泵铝制壳体表面修复

4. Repairing Aluminum Parts 修理铝制零件D.Method No. 404D: Fuel and Oil Pump Aluminum Housing Surface RepairMethod No. 404D:燃油和滑油泵铝制壳体表面修复Repair worn and/or damaged s...

SECTION IV – REPAIR 5.清除钢制零件上的损伤-A.Method No. 405A:微小表面缺陷修复

5.Removing Damage from Steel Parts清除钢制零件上的损伤A.Method No. 405A: Minor Surface Defect RepairMethod No. 405A:微小表面缺陷修复Repair minor surface defects on steel parts as f...

SECTION IV – REPAIR 5.清除钢制零件上的损伤-B.Method No. 405B:去除严重腐蚀、硬碳、油漆和氧化皮

5.Removing Damage from Steel Parts清除钢制零件上的损伤B.Method No. 405B: Heavy Corrosion, Hard Carbon, Paint, and Scale RemovalMethod No. 405B:去除严重腐蚀、硬碳、油漆和氧化皮Remov...

1266-100 DIFFERENTIAL PRESSURE SWITCH

一、名称DIFFERENTIAL PRESSURE SWITCH压差开关二、件号1266-100三、章节号52-73-12四、适用机型A320五、系统52-DOORS舱门六、安装位置811 客舱门和应急门位置七、部件原理压差开关主要是感应法...

SECTION IV – REPAIR 14-零件重新标记

14. Remarking Parts 零件重新标记Before to start cleaning, locate the marks that can be removed by the cleaning and repainting process. Those marks must be identified and recorded. ...

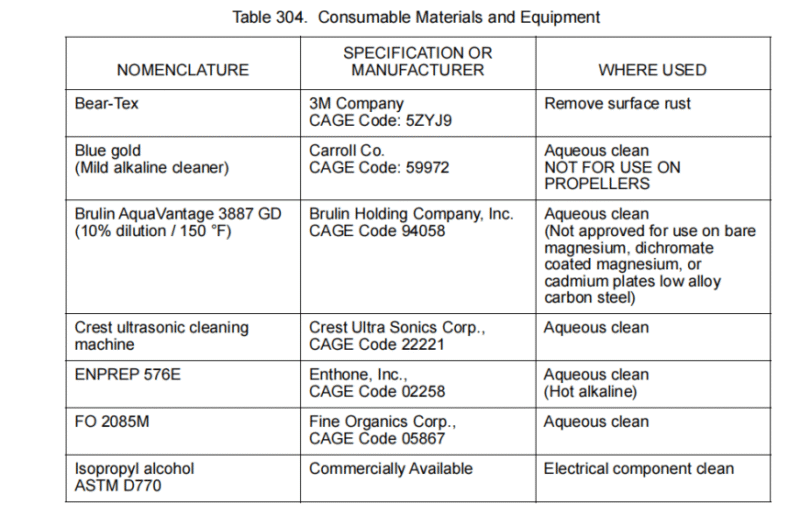

SECTION IV – REPAIR 2.溶液制备

2.Preparation of Solutions溶液制备WARNING: SOLUTIONS USED FOR CLEANING ARE HAZARDOUS. AVOID INHALING FUMES, DUST, OR MIST. AVOID CONTACT WITH SKIN. AFTER PREPARATION, WASH HANDS AN...

SECTION IV – REPAIR 3. 防护涂料及电镀的修复与应用-A.Method No. 403A: 阳极氧化铝和铝合金修复

3. Repair and Application of Protective Coatings and Plating 防护涂料及电镀的修复与应用A.Method No. 403A: Anodized Aluminum and Aluminum-alloy RepairMethod No. 403A: 阳极氧化铝和铝...

清洁 二 CLEANING

4. Abrasive Cleaning Procedures 磨料清洗程序 A. Deleted. 已删除。 B. Task 1: Dry Abrasive Blast 任务1:干式磨料喷砂 CAUTION: DO NOT USE DRY ABRASIVE BLAST ON SURFACES WITH 63 RA OR...

SECTION IV – REPAIR 3. 防护涂料及电镀的修复与应用-E.Method No. 403E:干膜润滑剂修复

3. Repair and Application of Protective Coatings and Plating 防护涂料及电镀的修复与应用E.Method No. 403E: Dry-film Lubricant RepairMethod No. 403E:干膜润滑剂修复Dry-film lubricant...