分类

子分类

排序

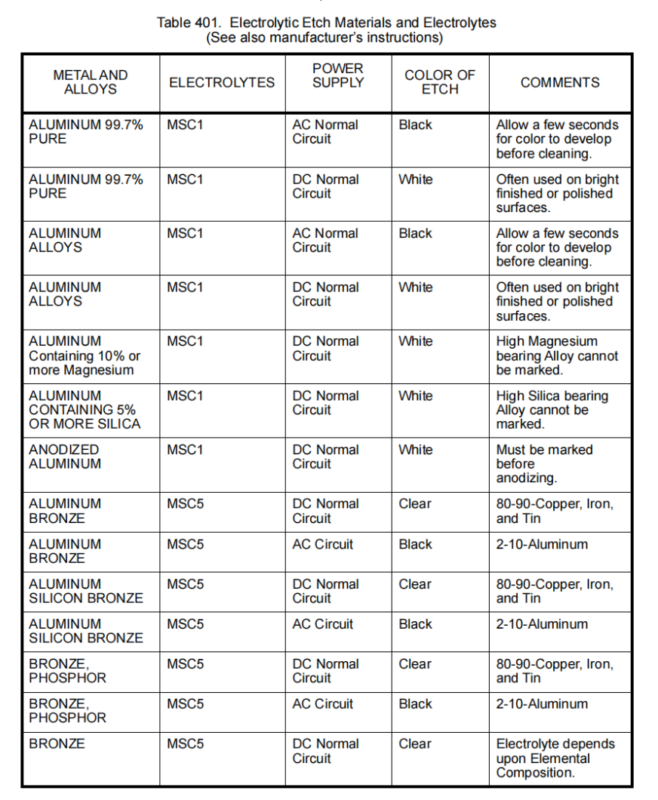

MARKING 标识

CAUTION: DO NOT USE THE MECHANICAL STANDARD PRACTICES MANUAL BY ITSELF. USE IT ONLY AS SPECIFIED IN THE APPLICABLE COMPONENT MAINTENANCE MANUAL OR OTHER FAA-APPROVED DOCUMENTS...

SOPM20-70-01飞机部件的保护、储存和处理

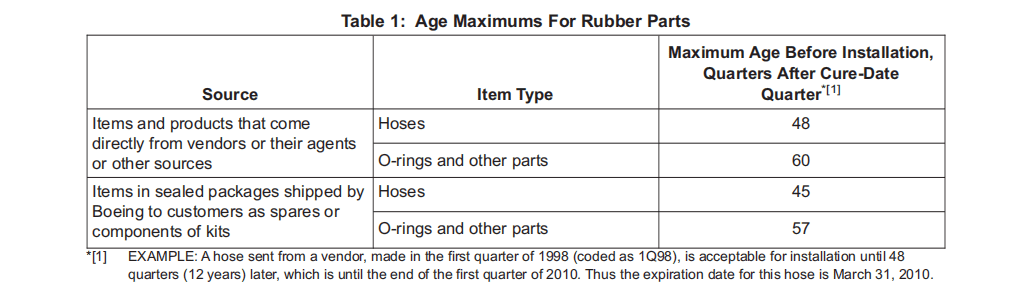

飞机部件的保护、储存和处理PROTECTION, STORAGE AND HANDLING OF AIRPLANE COMPONENTS1. INTRODUCTION 介绍A. The data in this subject comes from Boeing Process Specifications BAC5401, B...

清洁 二 CLEANING

4. Abrasive Cleaning Procedures 磨料清洗程序 A. Deleted. 已删除。 B. Task 1: Dry Abrasive Blast 任务1:干式磨料喷砂 CAUTION: DO NOT USE DRY ABRASIVE BLAST ON SURFACES WITH 63 RA OR...

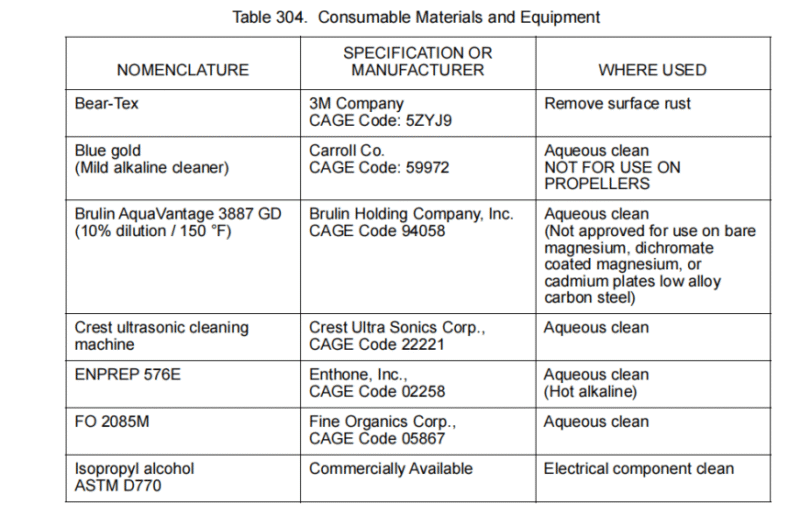

清洁 一 CLEANING

CAUTION: DO NOT USE THE MECHANICAL STANDARD PRACTICES MANUAL BY ITSELF. USE IT ONLY AS SPECIFIED IN THE APPLICABLE COMPONENT MAINTENANCE MANUAL OR OTHER FAA-APPROVED DOCUMENTS. 注...

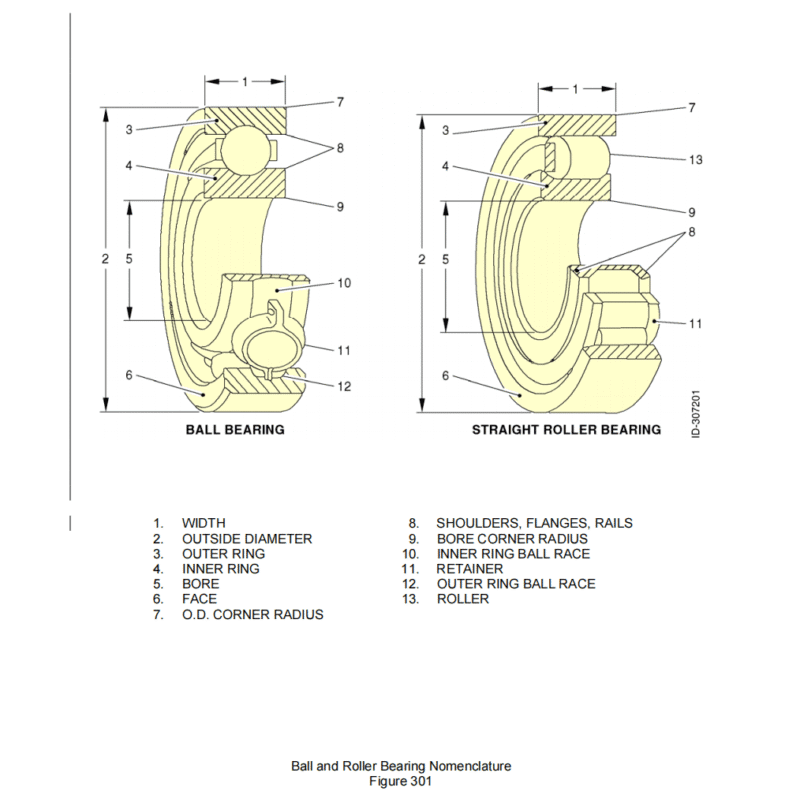

SECTION III – INSPECTION 1. Standard Inspection Practices -E. 轴承检查

E. Bearing Inspection轴承检查(1) Separable Bearings:可分解的轴承。Table 301. Separable Bearing Defect Definitions表301 可分解轴承缺陷的定义Term项目Definition (Description of Defect...

SECTION III – INSPECTION 1. Standard Inspection Practices -H. 电气组件检查

H. Electrical Component Inspection 电气组件检查CAUTION: REFER TO APPLICABLE MANUAL PRIOR TO PERFORMING ANY ELECTRICAL CHECKS TO ENSURE THAT CHECKS WILL NOT DAMAGE EQUIPMENT.注意:...

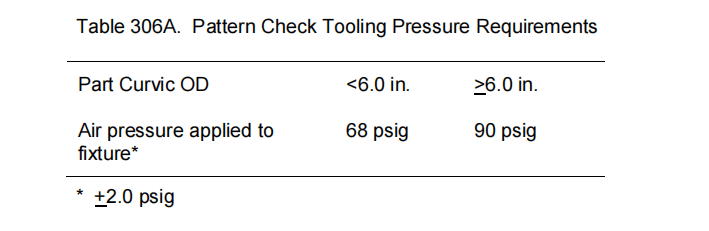

SECTION III – INSPECTION 1. Standard Inspection Practices -I.弧形联轴器检查

I.Curvic Coupling Inspection 弧形联轴器检查NOTE: Nomenclature for curvic coupling is provided in Figure 320.注:图 320 中提供了弧形联轴器的命名。(1) Inspect components with curvic ...

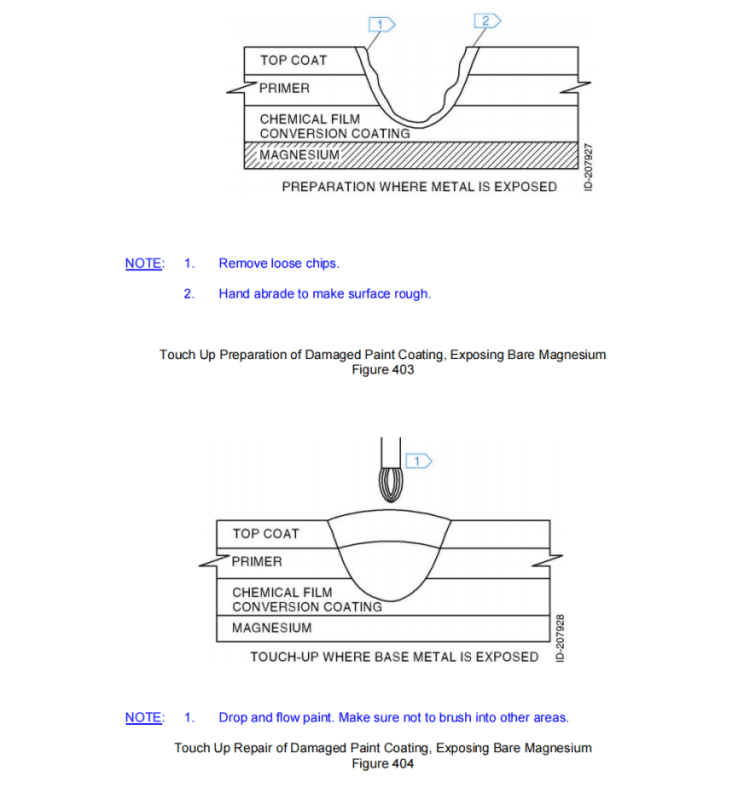

SECTION IV – REPAIR 3. 防护涂料及电镀的修复与应用-L.Method No. 403L: 修复因底漆和面漆损坏而暴露裸露镁的油漆涂层-环氧胺体系

3. Repair and Application of Protective Coatings and Plating 防护涂料及电镀的修复与应用L.Method No. 403L: Repair of Paint Coatings Damaged Through Primer and Paint Topcoat, Exposin...

HOEYWELL INTRODUCTION 介绍

INTRODUCTION介绍 1. General 通用 Information provided in this manual pertains to overhaul and repair processing for parts manufactured by Honeywell Inc., Phoenix, Arizona. 本手册提...

SECTION IV – ASSEMBLY 8-Marman卡箍(联轴器)安装

8.Marman Clamp (Coupling) InstallationMarman卡箍(联轴器)安装(1) Position clamp over mating component flanges as described in applicable manual.参照适用手册说明,将卡箍定位于配合...

SECTION III – INSPECTION 1. Standard Inspection Practices 标准检查施工

SECTION III – INSPECTION第三章 – 检查TABLE OF CONTENTS目录SECTION章节1. Standard Inspection Practices标准检查施工A. General通用B. General Inspection Procedures通用检查程序C. Magn...

SECTION VI – PACKAGING – 包装(完)

SECTION VI - PACKAGING包装 1.General概述Refer to applicable manual for unit in work for general packaging procedures. For APUs, refer to Service Bulletin 49-7997 for Preservation ...

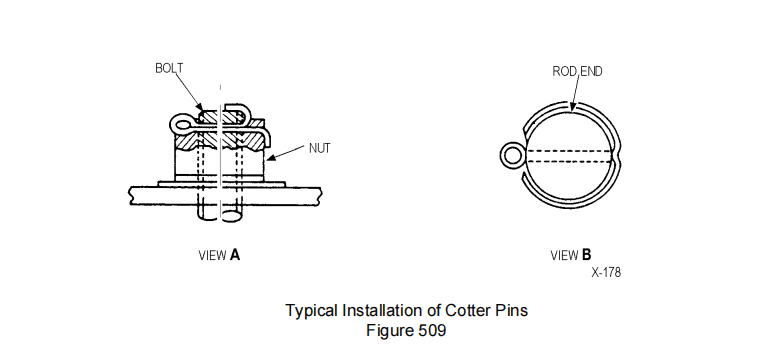

SECTION IV – ASSEMBLY 7 -开口销与键形垫圈

7.Cotter Pins and Key Washers开口销与键形垫圈CAUTION: COTTER PINS ARE NOT REUSABLE. INSTALL NEW COTTER PIN AS SPECIFIED IN APPLICABLE MANUAL FOR UNIT IN WORK.注意:开口销不可重复使...

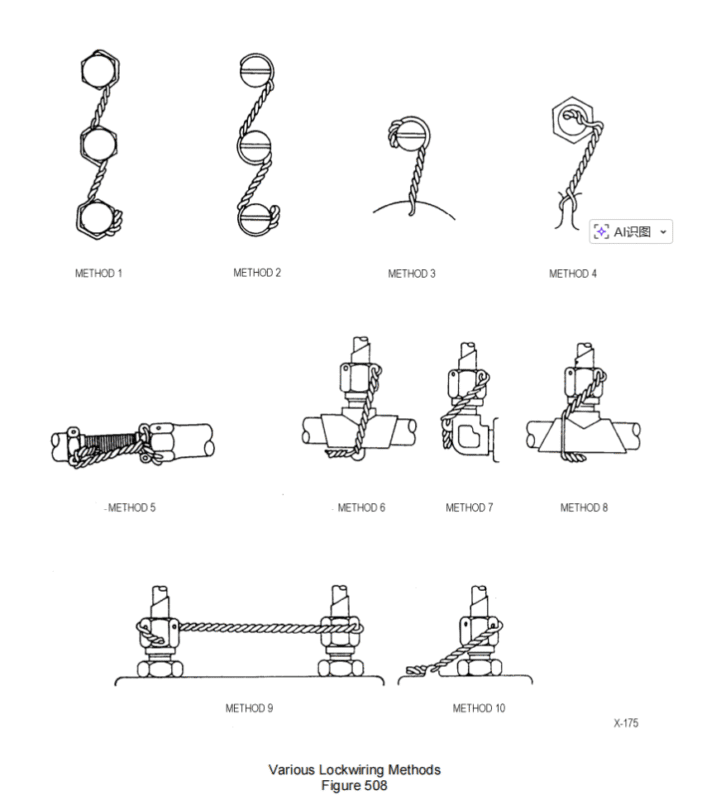

SECTION IV – ASSEMBLY 6 -保险丝安装与技术

6.Lockwire Installation and Techniques保险丝安装与技术A.General概述Appropriate diameter lockwire (specified in Aerospace Standard 567) is installed using the following techniques a...

SECTION IV – ASSEMBLY 5 -扭矩要求

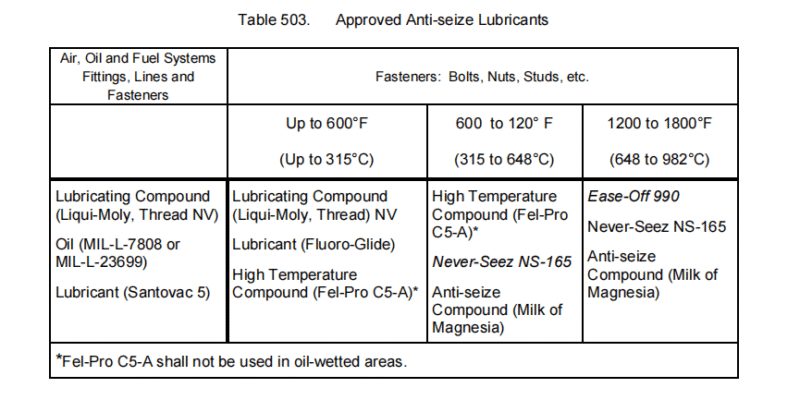

5. Torque Requirements 扭矩要求 Torque requirements for air, oil and fuel system components depend on the type of parts being fastened or tightened. 空气、滑油及燃油系统组件的扭矩...

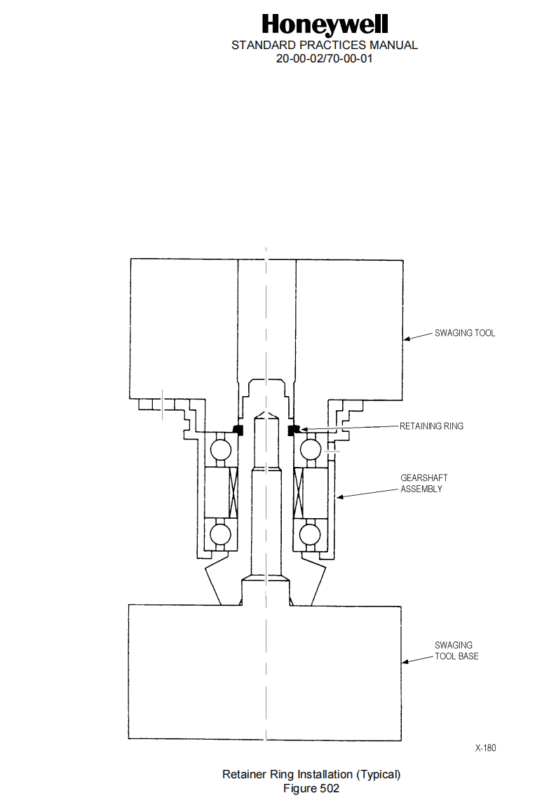

SECTION IV – ASSEMBLY 4-压装过盈配合零件

4.Pressing Interference Fit Parts压装过盈配合零件CAUTION: DURING ASSEMBLY OF SOME UNITS, CLOSE TOLERANCE FITS REQUIRE THAT A PART WILL EITHER HAVE TO BE COLD SOAKED OR HEATED IN OR...

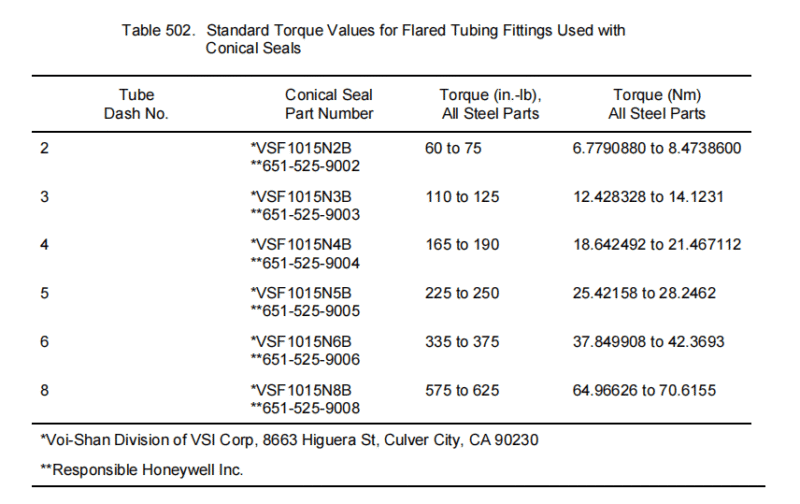

SECTION IV – ASSEMBLY 3-锥形密封件

3.Conical Seal锥形密封件NOTE: Conical seals are used at specific locations during engine production to preclude leakage. However, conical seals may be used at any flared tubing fit...